Disinfection using UV

UV-C light (200–280 nm) is also known as ultraviolet germicidal radiation and is commonly used to sterilize equipment’s and create sterile environments, as well as to inactivate microorganisms in the food and water industries. Since 1909, UV-C radiation has been used to disinfect drinking water, and it is a safe and effective method. Waterborne pathogens in drinking water have varying degrees of susceptibility to UV radiation, with bacteria and protozoa being the most susceptible, followed by viruses, bacterial spores, Adenovirus (the only virus with minimal sensitivity to UV), and algae, which are the least sensitive.

UV disinfection systems are utilized in a variety of applications, from the purification of drinking water in individual households to the disinfection of whole municipal water supplies to the treatment of industrial wastes. UV water treatment is widely regarded as a safer and more cost-effective method of disinfecting wastewater in industrial settings.

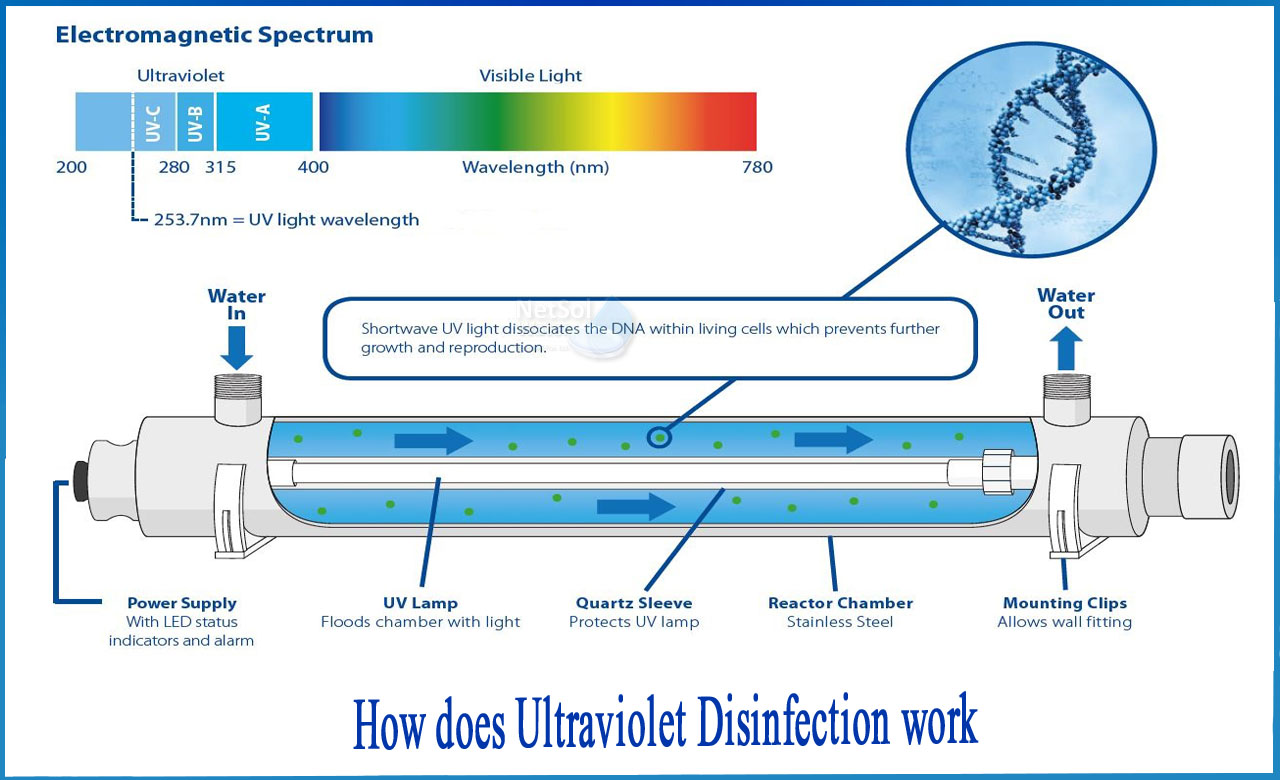

Components of a UV disinfection system

The UV disinfectant system consists of four basic components, each of which play a significant function in disinfection. The next sections go through the specifics of these components.

1: Reactor chamber:In most applications, the reactor chamber is an enclosed structure composed of stainless steel. The reactor chamber is the casing that holds the UV disinfectant system's other three main components. The whole water purifying process takes place within this reactor chamber. The chambers come in a variety of forms and port sizes, depending on the UV disinfectant system's needed flow rate. Regardless of the aesthetics of the reactor chambers, they all serve the same purpose: to support or enclose the assembly.

2: UV Lamp: As part of a UV disinfection system, the UV lamp is unquestionably the most critical component. The UV lamps are used to disinfect the system by emitting the germicidal UV-C wavelength. UV lights contain mercury, which may pose a health risk to humans, but only in trace amounts, about the size of a bead. These lamps have filaments, much as ordinary bulbs, that create an electric current. The mercury inside the lamp is heated by the current, which evaporates but stays in the air inside the lamp. This vaporized mercury aids in the production of electrical arcs, which emit UV rays of varying intensities, which are used to disinfect water. UV lamps come in different forms as:

-Standard UV lamps: Low-pressure UV lamps are utilized in residential water treatment equipment and are known as standard UV lamps.

-High output UV lamps:UV lamps with a high output but low pressure is known as high output UV lamp. These lights have a high flow rate yet have a smaller footprint. These lamps are utilized in water disinfection applications with a high or moderate capacity.

-Amalgam UV lamps:UV lamps that employ vaporized mercury to boost the intensity of UV light are known as amalgam UV lamps. In commercial UV disinfection systems, these lamps are employed.

3: The Quartz Sleeve: The UV light is protected by the quartz sleeve. To keep the lightsecure from the flow of water, it is fitted inside this long cylindrical glass tube.

4: Ballast/Controller Unit: The ballast is a control unit that ensures that the UV lamp's electrical output is maintained. The strength of the radiations varies depending on the control unit's electrical supply.

How does Ultraviolet disinfection work?

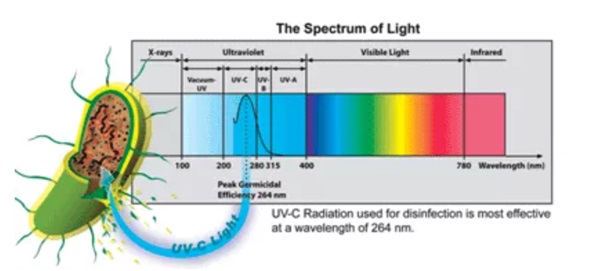

UV light disinfects by entering microbes and destroying their DNA in UV water disinfection technology. Because DNA plays such an essential part in the activities and reproduction of organisms, deleting it hinders them from being active and proliferating. UV radiation (wavelength 240-280 nm) is also present in very modest amounts in natural sunshine. With the aid of high mercury discharge lamps, also known as UV lamps, the same energy is generated at higher intensities.

When exposed to the right amount of UV radiation, noviruses, bacteria,moulds, or their spores can survive. As a result, UV is regarded the greatest method for water sterilization, and a UV mobile sterilizer equipment may be utilized for room sterilization.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated water and wastewater problems by strategically integrating modern treatment technology with practical solutions.

If you need technical help and guidance, or simply have a query regarding our water and wastewater treatment technology solutions, contact one of our expert advisers via phone at +919650608473 or contact via email at enquiry@netsolwater.com