How to Calculate Baffling Factor?

The baffling factor measures how effectively water flows through treatment tanks. This calculation helps engineers design efficient water treatment systems. Water treatment plants use the baffling factor to determine contact time between disinfectants and water. Engineers need accurate baffling factors to ensure proper water treatment. The factor ranges from 0.1 to 1.0 based on tank design and flow patterns. A higher baffling factor indicates better mixing and contact time. Treatment plants must achieve specific contact times for proper disinfection. The baffling factor directly affects these calculations. This knowledge helps operators maintain safe drinking water standards. Understanding baffling factor calculation improves treatment system design and operation.

Understanding Basic Concepts

The baffling factor calculation requires knowledge of several fundamental concepts. Engineers must understand flow patterns and hydraulic efficiency. These basics form the foundation for accurate calculations. Let us explore the essential concepts behind baffling factors.

Flow Patterns

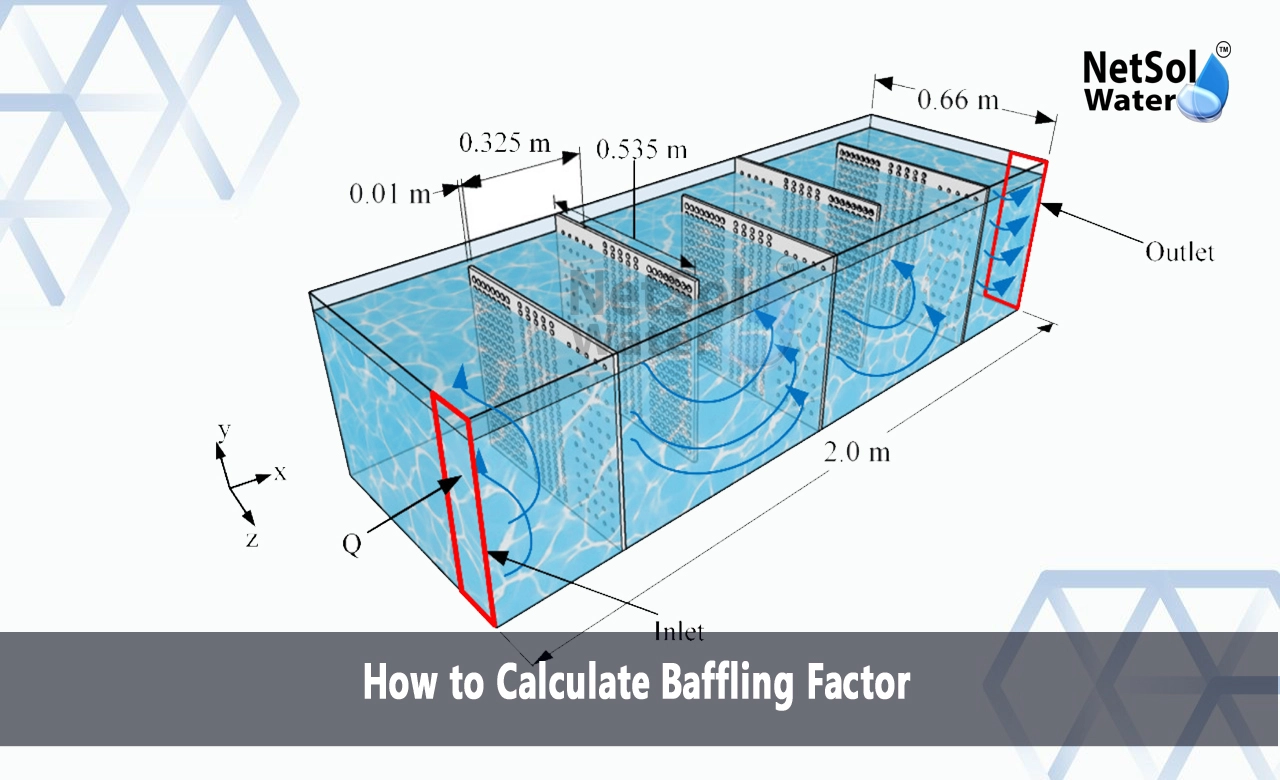

Water moves differently through various tank designs. Short-circuiting reduces effective contact time. Good baffling creates uniform flow patterns. Tank design influences these patterns directly.

Retention Time

Theoretical retention time differs from actual time. The baffling factor accounts for this difference. Engineers calculate actual contact time using this factor. This ensures adequate disinfection time.

Tracer Studies

Dye tests reveal actual flow patterns. Engineers measure dye concentration over time. These studies determine real retention times. The results help calculate baffling factors.

Calculation Methods and Formulas

Engineers use specific methods to determine baffling factors. These calculations require accurate measurements. The process follows established guidelines. Let us examine the calculation procedures.

Basic Formula

The baffling factor equals actual time divided by theoretical time. Engineers measure both times through tracer studies. This gives the basic efficiency ratio. Simple calculations produce useful results.

Advanced Calculations

Complex systems need detailed analysis. Engineers consider multiple flow paths. Computer models help analyze flow patterns. These tools improve accuracy.

Factor Adjustments

Different tank types need various adjustments. Engineers apply correction factors. Temperature affects calculations. These adjustments improve accuracy.

Applications and Practical Use

Treatment plants apply baffling factors in daily operations. The calculations affect many treatment processes. Engineers use these values for system design. Let us look at practical applications.

Disinfection Systems

Contact time calculations need baffling factors. Engineers size chlorine contact tanks. Operators adjust chemical doses. These applications ensure safe water.

System Design

Engineers design better treatment systems. Good baffling improves efficiency. Tank modifications increase performance. These improvements save money.

Performance Monitoring

Operators track system efficiency. Regular testing confirms calculations. Performance data guides improvements. This monitoring maintains treatment quality.

Conclusion:

Do you need help calculating the baffling factor for your treatment system? Our engineering team provides expert guidance for your calculations. We offer comprehensive tracer studies and system analysis. Contact us today to improve your treatment system efficiency through proper baffling factor calculations. Our experts will help optimize your water treatment process.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com