Zero liquid discharge (ZLD)-

All water is collected and impurities are converted to solid waste in a zero liquid discharge (ZLD) approach to water treatment. While many water treatment methods aim to maximise freshwater recovery while minimising waste, ZLD is the most difficult to achieve since the expense and difficulty of recovery rises as the wastewater becomes more concentrated. Salinity, scaling organics and compounds all have higher concentrations, which adds to the costs of handling them. ZLD is done by connecting water treatment technologies that can treat wastewater as contaminants become more concentrated.

What Is the Importance of Zero Liquid Discharge?

Industrial operations, in a world where freshwater is becoming a more important resource, endanger its supply on two fronts unless the water is treated. Many industrial operations require water, which reduces the amount of water available for the environment or other activities, or pollutes and releases water that harms the surrounding ecosystem. Another compelling argument to adopt zero liquid discharge is the possibility of recovering valuable resources from wastewater. Some businesses choose ZLD for their waste since they can sell the solids produced or reuse them in their manufacturing process. Lithium, for example, has been found in oil field brines in the United States at nearly the same concentration as in South American salars. Another example is the recovery of gypsum from mine water and flue gas desalination (FGD) effluent, which can subsequently be sold for use in the production of drywall.

Benefits of ZLD:

Targeting zero liquid discharge for an industrial process or facility has a number of advantages:

- ~ Waste management costs are reduced when waste volumes are reduced.

- ~ Reduce water purchase expenses and risk by recycling water on-site. When compared to treating to fulfil severe environmental discharge criteria, recycling on-site can result in reduced treatment demands.

- ~ Reduce the number of trucks used for off-site waste water disposal, as well as the greenhouse gas emissions and risk of local traffic accidents.

- ~ Environmental performance has improved, as has the regulatory risk profile for future permits.

- ~ Some techniques, such as ammonium sulphate fertiliser or sodium chloride salt for ice melting, can restore important resources.

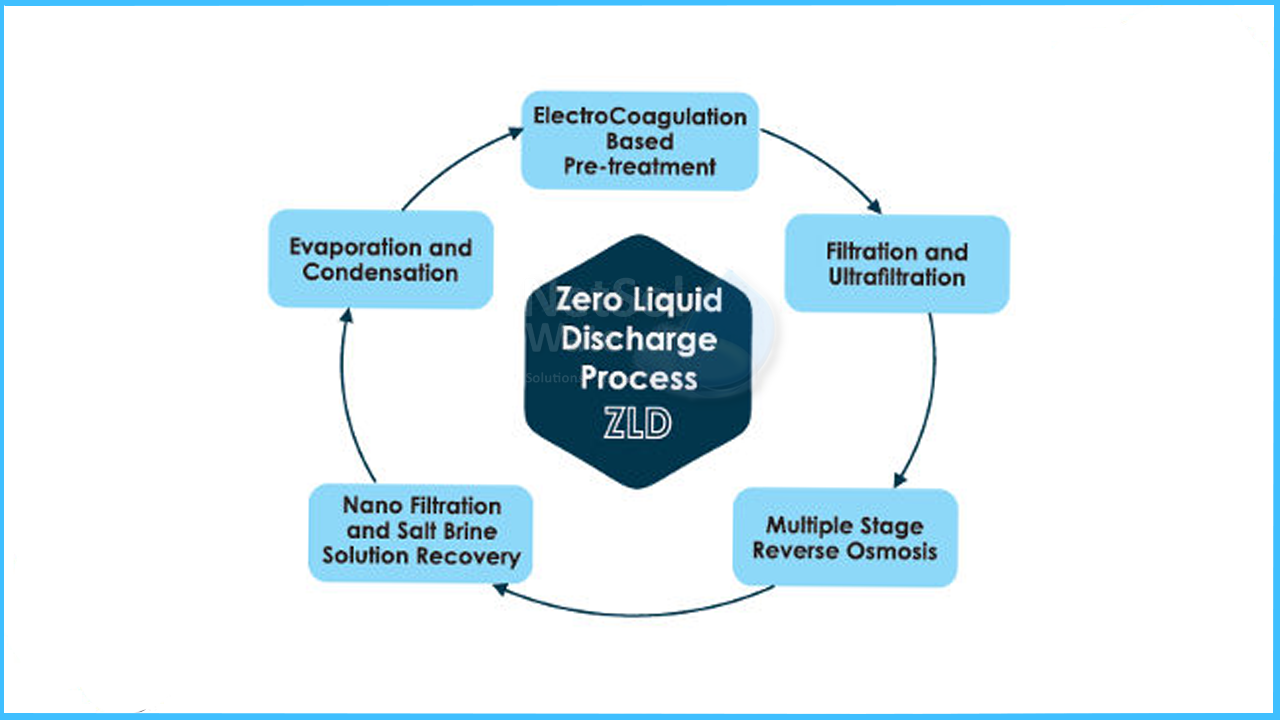

What does a basic ZLD treatment system include?

The exact components of a ZLD treatment system will be determined by three factors:

1. The amount of dissolved material in the waste,

2. The system's minimum flow rate, and

3. The presence of specific contaminants. However, in general, a simple ZLD treatment system will comprise one or more of the following:

- ~ clarifier

- ~ chemical feed

- ~ filter press

- ~ ultrafiltration (UF)

- ~ reverse osmosis (RO)

- ~ brine concentrators

- ~ evaporator

- ~ crystallizer

These conventional components are normally acceptable depending on the needs of your plant and process; however, if your plant requires a system with a little more customisation, you may need to add additional features or technologies. Because of the wide diversity of businesses that use ZLD and the varied waste streams that are generated, ZLD is a highly customised process, and these add-ons will be based on your facility's specific requirements.