What do you mean by clarifiers in a sewage treatment plant?

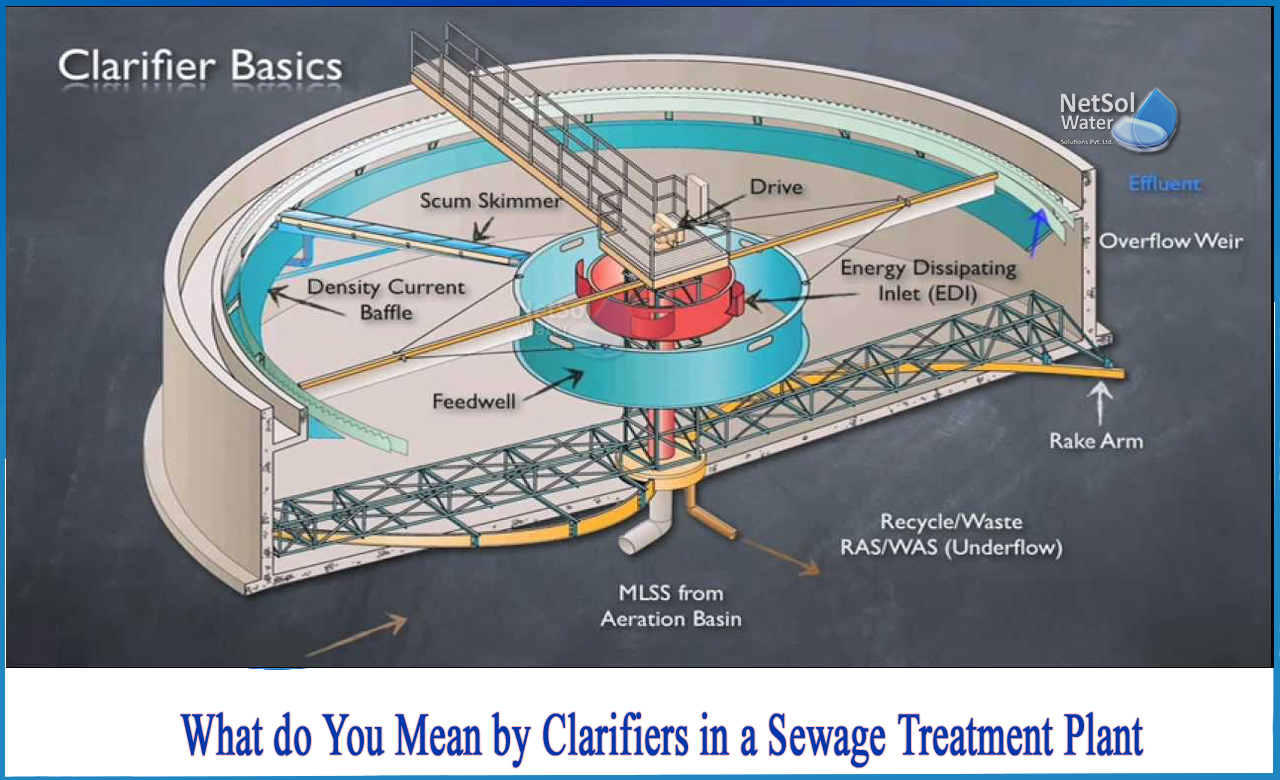

Clarifiers are settling tanks equipped with mechanical means to remove solids deposited by sedimentation on a continuous basis. A clarifier is a device that removes solid particulates or suspended solids from liquids in order to clarify and/or thicken them. Solid contaminants settle to the bottom of the clarifier tank and are collected by a scraper mechanism. Sludge refers to concentrated impurities discharged from the tank's bottom, whereas scum refers to particles that float to the liquid's surface.

Waste water treatment:

For millennia, sedimentation tanks have been used to treat wastewater. Sedimentation is the primary method of removing floating and settleable solids from sewage. Primary clarifiers reduce the number of suspended solids and pollutants in the suspended solids. Due to the large amount of reagent required to treat domestic wastewater, preliminary chemical coagulation and flocculation are generally avoided, with remaining suspended solids being reduced by subsequent stages of the system.

Coagulation and flocculation, on the other hand, can be used to build a compact treatment plant (also known as a "package treatment plant") or to further polish the treated water. Secondary clarifiers are sedimentation tanks that remove flocs of biological growth produced by some secondary treatment methods such as activated sludge, trickling filters, and rotating biological contactors.

Pre-treatment:

Coagulation and flocculation reagents, such as polyelectrolytes and ferric sulphate, can be added to the water before it enters the clarifier. These reagents cause finely suspended particles to clump together and form larger, denser particles known as flocs, which settle more quickly and steadily. This allows for more efficient and easy separation of solids in the clarifier, which aids in energy conservation. Using these processes to isolate the particle components first may reduce the volume of downstream water treatment processes such as filtration.

Operation of clarifiers:

To preserve and encourage positive clarifier processing, it is necessary to first eliminate any corrosive, reactive, and polymerisable components, as well as any material that may foul the outlet stream of water, in order to avoid any unwanted side reactions, changes in the product, or damage to any of the water treatment equipment.

This is accomplished through routine inspections to determine the extent of sediment build-up, as well as frequent cleaning of the quiescent zones, as well as the inlet and outlet areas of the clarifier, to eliminate any scouring, litter, weeds, or debris that has accumulated over time.

The velocity of the inlet flow should be reduced as water is introduced into the clarifier. Reduced velocity increases the hydraulic retention time inside the clarifier for sedimentation and helps to avoid excessive turbulence and mixing, promoting effective settling of suspended particles. To discourage overt mixing within the clarifier and increase the retention time for the particles to settle, the inlet flow should be distributed evenly across the entire cross section of the settling zone within the clarifier, where the volume is kept at 37.7 percent capacity.

If the sludge formed at the bottom of each clarifier is left for an extended period of time, it can become gluey and viscous, making removal difficult. This sludge formation promotes anaerobic conditions and a healthy environment for bacterial growth. This can result in particle resuspension by gases and the release of dissolved nutrients throughout the water fluid, reducing the clarifier's effectiveness. Major health issues and problems can also occur further down the water purification system's track, or the health of the fish found downstream of the clarifier may be jeopardised.

For more information, contact Netsol Water.