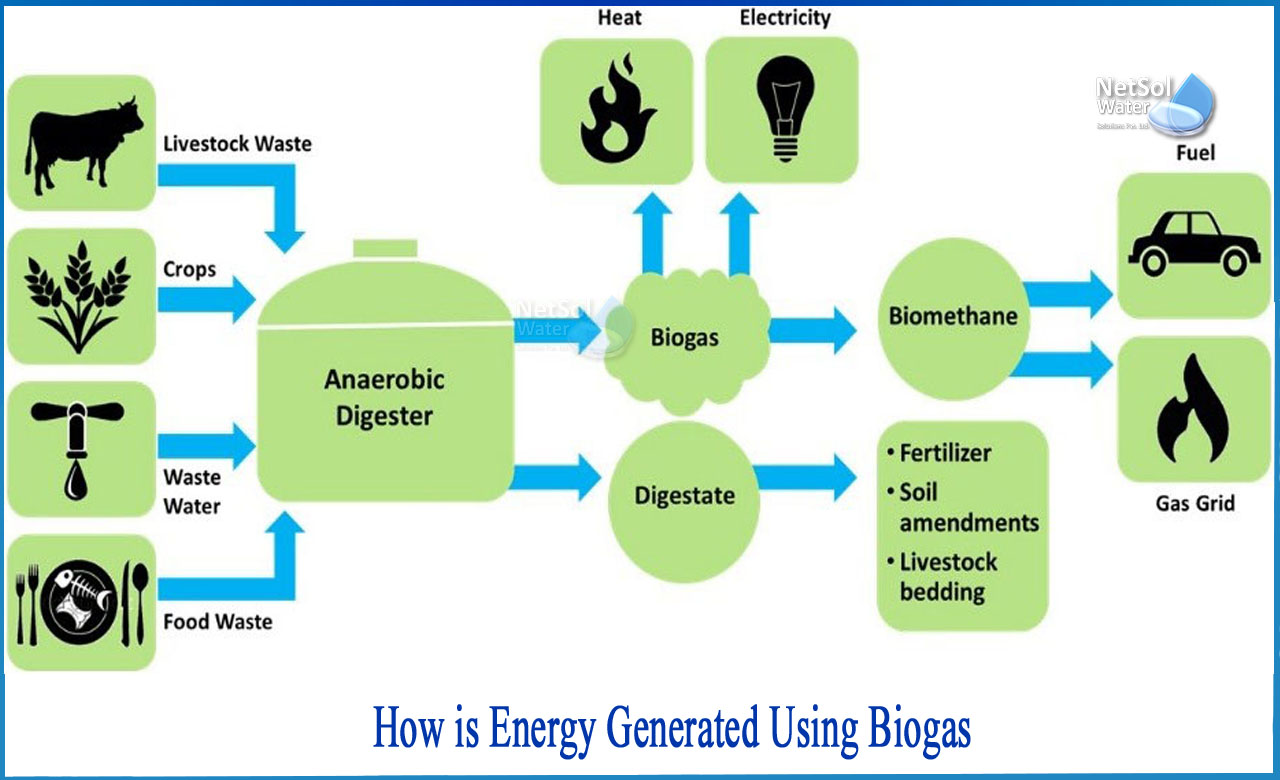

How to energy generated using Biogas?

Biogas is a flammable gas created in an anaerobic biogas reactor during the anaerobic digestion of organic materials (e.g. small-scale digester, biogas settler, digestion of organic waste, anaerobic baffled reactor, etc.). Wastes are handled and decomposed, and biogas is created, during anaerobic digestion. Anaerobic treatment also has the advantage of emitting fewer greenhouse gases than aerobic treatment. Biogas is thus a renewable green energy source.

Composition of Biogas

Biogas is mostly composed of methane (CH4, 65-70%), carbon dioxide (CO2, 25-30%), and different amounts of water (H2O), hydrogen sulphide (H2S), and other trace chemicals, which can be found in waste dump (e.g. ammonia, NH3, hydrogen H2, nitrogen N2, and carbon monoxide, CO). Many factors, such as the type of digester and the type of organic waste, influence the amount of each gas in the combination. To attain a high conversion rate, variable sludge composition necessitates various/specialized reactor designs.

When it comes to using biogas as a fuel, methane is the most valuable component. Biogas has a calorific value of roughly 6 kWh/m3, which is equivalent to about half a litre of diesel oil, and can be used as a heat source or to generate power. Biogas must be dehumidified and purified before burning in all circumstances; otherwise, the gas engine will be damaged.

Technologies for conversion

On a domestic level, there are a variety of technologies for generating power from biogas.

In theory, a heat engine converts the chemical energy of combustible gases into mechanical energy in a regulated combustion system. This mechanical energy then turns into electrical energy by activating a generator. Gas turbines and combustion engines are the most popular heat engines utilized in biogas energy conversion. Internal combustion engines (such as reciprocating engines) and external combustion engines are two types of combustion engines (e.g. Sterling engine).

Combustion engines are suitable for small-scale heat engines because they are more efficient and less expensive than small gas turbines. Gas turbines, on the other hand, maybe more efficient when used in a cogeneration cycle that produces both heat and electricity.

Cogeneration, often known as combined heat and power (CHP), is the process of producing both electricity and useful heat at the same time. In general, heat engines (also known as thermal power plants) do not convert all of their thermal energy into electricity. In most circumstances, a little more than half of the energy is lost as heat.

CHP uses heat that would otherwise be lost in a normal power plant by trapping it, resulting in an efficiency of up to 89 %, compared to 55%for the best conventional plants. This means that in order to create the same quantity of useful energy, less fuel is required.

Applicability

The technology is versatile and can be used in the home or in the community. The reactors should be placed close to the CHP where the gas can be utilized to reduce distribution losses. The electricity can be consumed in the home or company, or it can be sold back into the electric power systems if grid management allows it.

What does Netsol Water provide?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish. We are committed to providing our valued customers with hands-on service, expert counselling, and training.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.