How Does the MBBR Process Work in Sewage Treatment Plants?

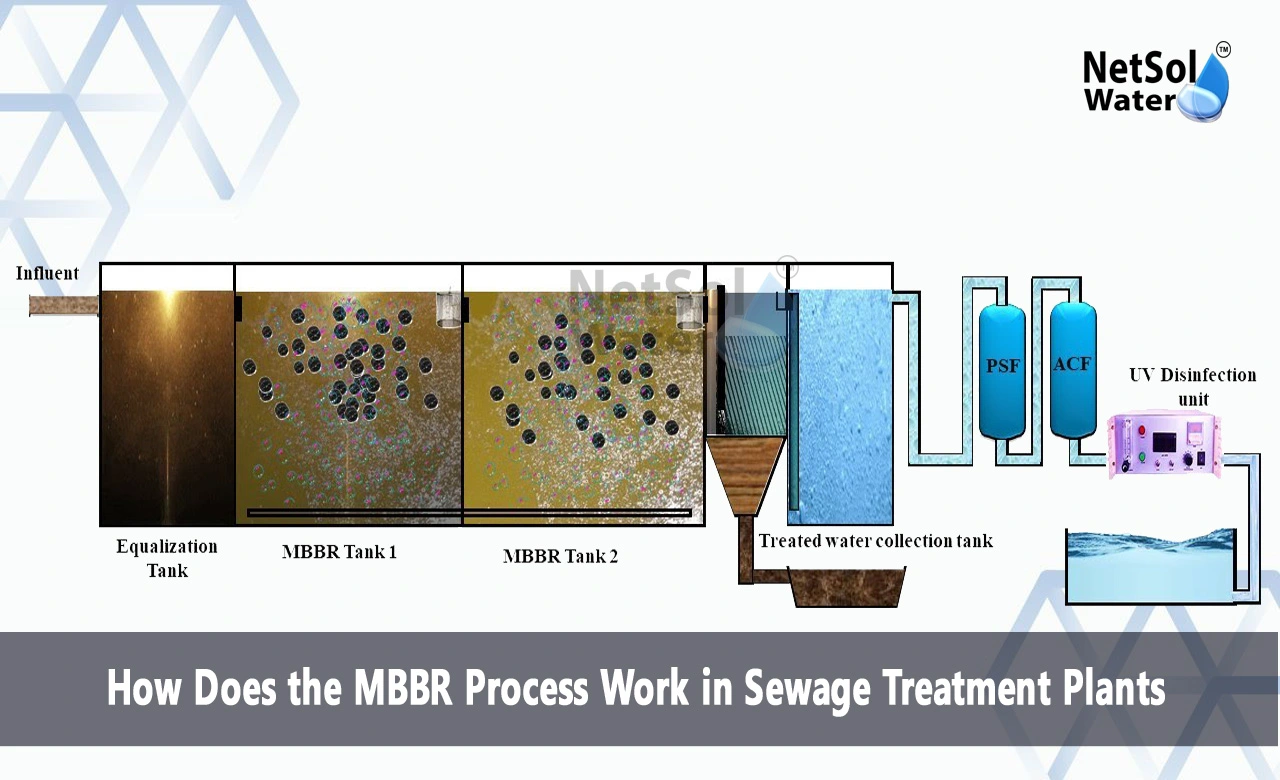

Effective sewage treatment is crucial for protecting public health and maintaining a healthy environment. As urban populations continue to grow and environmental regulations become more stringent, the demand for efficient and advanced sewage treatment technologies has risen significantly. One such innovative technology that has gained widespread adoption in sewage treatment plants is the Moving Bed Biofilm Reactor (MBBR) process. The MBBR process is a cutting-edge biological treatment system that utilises the principles of biofilm technology to achieve efficient removal of organic matter, nutrients, and other contaminants from wastewater. Unlike conventional activated sludge systems, which rely on suspended biomass, the MBBR process employs a unique approach where microorganisms grow as biofilms on small, free-moving plastic carriers suspended in the reactor.

We will explore the inner workings of the MBBR process, its operating principles, advantages, and applications in sewage treatment plants worldwide.

Understanding the MBBR Process

The MBBR process is a variation of the traditional activated sludge process but with a distinct and innovative approach. At the heart of the MBBR system lies a reactor basin filled with millions of small, high-density plastic carriers or media. These carriers, typically made from polyethene or polypropylene, are designed with a high surface area-to-volume ratio to maximise biofilm growth.As the wastewater enters the reactor, it comes into contact with the carriers, which are kept in constant motion by aeration or mechanical mixing. This motion prevents the carriers from settling and ensures uniform distribution of dissolved oxygen and nutrients throughout the reactor.

The key to the MBBR process lies in the formation of biofilms on the surface of these carriers. Biofilms are complex communities of microorganisms, primarily bacteria that attach to the carriers and form a thin, slimy layer. These microorganisms are responsible for breaking down and metabolising the organic matter and nutrients present in the wastewater, effectively treating and purifying it.

Biofilm Formation and Growth

The formation and growth of biofilms on the MBBR carriers are critical to the success of the treatment process. Initially, the carriers are seeded with a diverse population of microorganisms, which begin to colonise the surface and form the first layer of the biofilm.As the biofilm matures, it develops a complex structure with different layers of microorganisms, each performing specific functions. The outer layers are typically composed of aerobic microorganisms that consume dissolved oxygen and break down organic matter. The inner layers consist of anaerobic microorganisms that perform processes such as denitrification, where nitrates are converted into nitrogen gas.

The continuous motion of the carriers within the reactor ensures that the biofilms receive a consistent supply of nutrients, oxygen, and wastewater, promoting their growth and metabolic activity. Additionally, the high surface area-to-volume ratio of the carriers allows for a greater concentration of biomass within the reactor, enhancing the treatment efficiency.

Advantages of the MBBR Process

The MBBR process offers several advantages over traditional activated sludge systems, making it an attractive choice for sewage treatment plants:

- High Treatment Efficiency: The biofilm approach in MBBR systems allows for a higher concentration of biomass, leading to improved treatment efficiency and higher removal rates of organic matter, nutrients, and other contaminants.

- Compact Footprint: MBBR systems require a smaller physical footprint compared to conventional activated sludge systems, making them suitable for space-constrained treatment facilities or retrofitting existing plants.

- Operational Flexibility: The MBBR process can be easily adapted to handle fluctuations in influent flow rates and contaminant loads, providing greater operational flexibility and resilience.

- Low Sludge Production: The biofilm configuration in MBBR systems results in lower sludge production, reducing the need for sludge handling and disposal, which can be a significant operational cost for treatment plants.

- Resistance to Shock Loads: The attached biofilm in MBBR systems is more resistant to toxic shock loads or sudden changes in influent characteristics, ensuring more stable and consistent treatment performance.

Applications of MBBR in Sewage Treatment Plants

The versatility of the MBBR process makes it suitable for a wide range of applications in sewage treatment plants, including:

- Municipal Wastewater Treatment: MBBR systems are widely used in municipal wastewater treatment plants for the removal of organic matter, nitrogen, and phosphorus from domestic sewage.

- Industrial Wastewater Treatment: MBBR technology can be adapted to treat industrial wastewater from various sectors, such as food processing, pharmaceutical, and chemical industries, where specific contaminants or high-strength wastewater may be present.

- Retrofitting Existing Plants: The compact design and operational flexibility of MBBR systems make them an attractive option for retrofitting or upgrading existing sewage treatment plants to improve treatment capacity and meet more stringent effluent regulations.

- Decentralized Treatment: MBBR systems can be effectively employed in decentralised or on-site sewage treatment solutions for remote communities, resorts, or industrial facilities where centralized treatment infrastructure is not readily available.

Integration and Process Optimization

While the MBBR process can be effective as a standalone treatment system, it is often integrated with other processes to achieve optimal treatment performance and meet specific effluent quality requirements. Some common integration strategies include:

- Primary Treatment: MBBR systems are frequently combined with primary treatment processes, such as screening and sedimentation, to remove larger solids and reduce the organic load before biological treatment.

- Membrane Bioreactors (MBRs): Combining MBBR technology with membrane filtration systems, known as MBBR-MBR hybrid systems, can produce high-quality effluent suitable for water reuse or discharge into sensitive receiving environments.

- Tertiary Treatment: MBBR effluent may undergo additional tertiary treatment processes, such as disinfection, advanced oxidation, or filtration, to further enhance water quality and meet specific discharge requirements.

Process optimisation techniques, such as adjusting carrier fill ratios, aeration rates, and nutrient dosing, can also be employed to fine-tune the MBBR system's performance based on the specific characteristics of the influent wastewater and treatment goals.

Conclusion

The Moving Bed Biofilm Reactor (MBBR) process has emerged as a game-changer in the field of sewage treatment, offering a highly efficient, compact, and flexible solution for removing organic matter, nutrients, and other contaminants from wastewater. By using the power of biofilm technology, MBBR systems provide a unique approach that maximises treatment performance while minimising operational costs and environmental impact.The key to the MBBR process lies in the formation of biofilms on small, free-moving carriers within the reactor basin. These biofilms, composed of diverse microbial communities, effectively break down and metabolise the contaminants present in the wastewater, ensuring efficient treatment and purification.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com