What is cooling?

The transfer of thermal energy from one medium to another is referred to as cooling. Cooling can be essential in industrial applications to ensure that processes do not overheat equipment or products. Because water has a high boiling point and a high specific heat, it is used as a medium to absorb heat in many cooling applications.Water quality is a critical aspect of cooling systems that is frequently overlooked. Many people mistakenly believe that once water reaches the various systems, the quality will be under control.

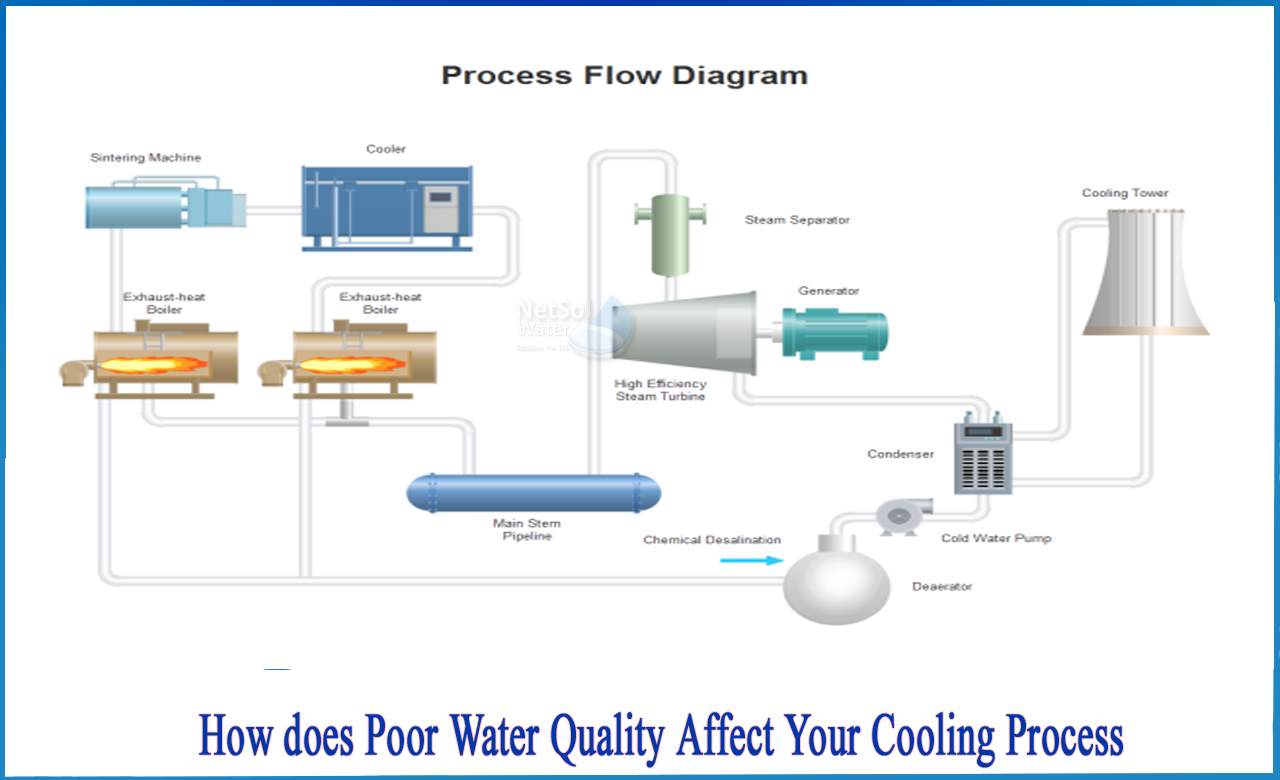

How does poor water quality affect your cooling process?

As water is an essential element of cooling process, quality of water should be carefully determined while choosing for the process.

If quality of water doesn’t match the level of guidelines, then it may affect the cooling process which results in heavy loss to the industries. Sometimes substances are picked up by the flow of water after it enters the system. These suspended solids can devastate a process cooling system and drastically reduce efficiencies.

What are the substances that can affect the water quality for the cooling process?

>Biofilm: When scale accumulates in a cooling system, biofilm starts to develop. Biofilm, which is made up of bacteria and proteins, can cause illness by fostering Giardia and other dangerous organisms. Furthermore, film buildup can induce many of the same inefficiency issues as scale collection. A cooling system that has accumulated a significant amount of biofilm can lose up to 30% of its operating efficiency.

>Metal particles that have corroded:Corrosion, which is affected by water temperatures, velocity, residence time, and metallurgy, is one of the leading causes of equipment failure. Biofilm is another factor that contributes to corrosion. Corrosion also causes the release of sediment into the water stream, which is then deposited to form scale. This scale causes the previously mentioned inefficiency issues. Furthermore, these deposits can cause equipment fouling, which can be expensive to repair.

>Dust Particles: Chemical programmes are extremely effective at purifying water before it enters the cooling system. Cooling towers, on the other hand, have gaps and vents that allow air and dust into the water stream. These suspended solids have the potential to degrade water quality and reduce efficiency. In 90 days, a cooling system with a cooling capacity of 1,300 tonnes can let in approximately 147 lbs. of dust.

Water also precipitates calcium carbonate when it comes into contact with metal pipes. This accumulation of dust and other fine particles in cooling systems forms a layer of scale over time. This scale is not only unpleasant, but it is also costly to resolve!

How is this issue resolved?

Many of the suspended solids pass through traditional filtration systems unnoticed. As a result, a system that can either clump or filter particles is required. Since most suspended solids enter the water stream after the water has entered the process cooling system, a post-hoc cleanup solution is the best solution.

A cross-flow micro-sand filtration system that can capture submicron particles is another option. A micro-sand filtration system incorporates a cross-flow conditioner and micro-sand filtration into the same vessel, resulting in high filtration efficiency. This method of filtration also reduces the amount of water required for backwash, making it suitable as a side-stream filtration solution for cooling system water.

Netsol water the best manufacturer of all types of water treatment plants. Water impurities are removed by NETSOL Reverse Osmosis, allowing you to reuse or drain it without harming the environment. RO systems are entirely self-contained, self-cleaning, and self-maintaining.