What are Membrane Bioreactors?

The membrane bioreactor (MBR) is a hybrid of the activated sludge and membrane separation processes. Membranes are utilized for liquid-solid separation instead of the traditional settling procedure and can be immersed in the biological reactor or positioned in a separate stage or compartment.

Basically, main sedimentation tank, final sedimentation tank and disinfection facility are not installed in this operation.

An anoxic tank and an aerobic tank make up the reaction tanks, with the membrane modules submerged in the aerobic tank. Biodegradation takes place in the membrane bioreactor, which receives pre-treated, screened influent.

The combined liquor is filtered and divided into solid and liquid using membrane modules in a reaction tank, which are removed by a water head difference or suction pump. During operation, the membrane's surfaces are continually wiped down by a mixed flow of air and liquid created by an air diffuser at the bottom of the reaction tank. The treated effluent is permeate from the membranes.

Applicability of MBR technology

Because there are no secondary sedimentation tanks, sand filters, or disinfection facilities installed, MBR systems allow for higher sewage flow or improved treatment performance in a smaller space than a conventional biological system using activated sludge.

Due to the high initial cost of the equipment and high operation and maintenance (O&M) expenses, this method has only been employed in small-flow systems in the past. They are, nevertheless, increasingly being utilized in bigger systems nowadays. Some industrial and commercial applications are also well suited for MBR systems.

MBR wastewater is especially useful for reuse and surface water discharge applications needing considerable nutrient (nitrogen and phosphorus) removal due to its excellent quality.

What is the Design Parameters of MBR systems?

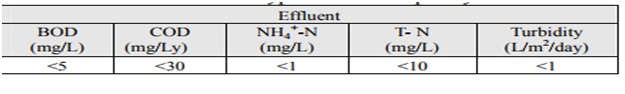

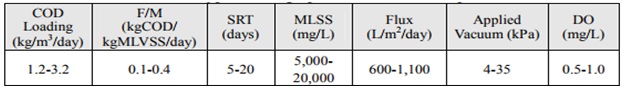

The usual design parameters of this process and effluent quality are integrated as indicated in the tables below, based on the performance of actual MBR processes and references on the MBR process.

Following are important factors for the design and management of MBR Process

a. Because a consistent volume of influent must be provided to membrane modules, a flow equalization tank must be installed to manage influent volume fluctuations;

b. Membranes can be divided into two types: Hollow fiber bundles and plate membranes. There is no difference in the effectiveness of removal between these two arrangements.

c. Because membrane permeation flux reduces as water temperature lowers, membrane capacity should be set with influent temperature in mind.

d. The aperture of the dividing wall between the anoxic tanks must be large enough to prevent reverse mixing between the tanks. Furthermore, the response tank should be covered to prevent extraneous objects from entering.

e. The total amount of air required in the aeration tank should be calculated taking into account the amount of air necessary for biological treatment and membrane washing.

f. In terms of operation and maintenance, it is advised that the installation include one additional membrane tank/unit beyond what the design would theoretically call for.

g. Some membrane types necessitate the use of a washing tank for membrane modules.

h. Membranes are either submerged in the biological reactor or in a separate vessel through which the mixed liquor from the biological reactor is cycled in MBR systems.

Why should you chose us for wastewater Treatment?

Netsol Water, based in Greater Noida, India, is a well-known industrial and commercial water and wastewater treatment plant manufacturer. We provide experienced treatment solutions for all of your needs. In accordance with industry standards, our treatment plants employ top quality raw materials and the most up-to-date equipment’s.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.