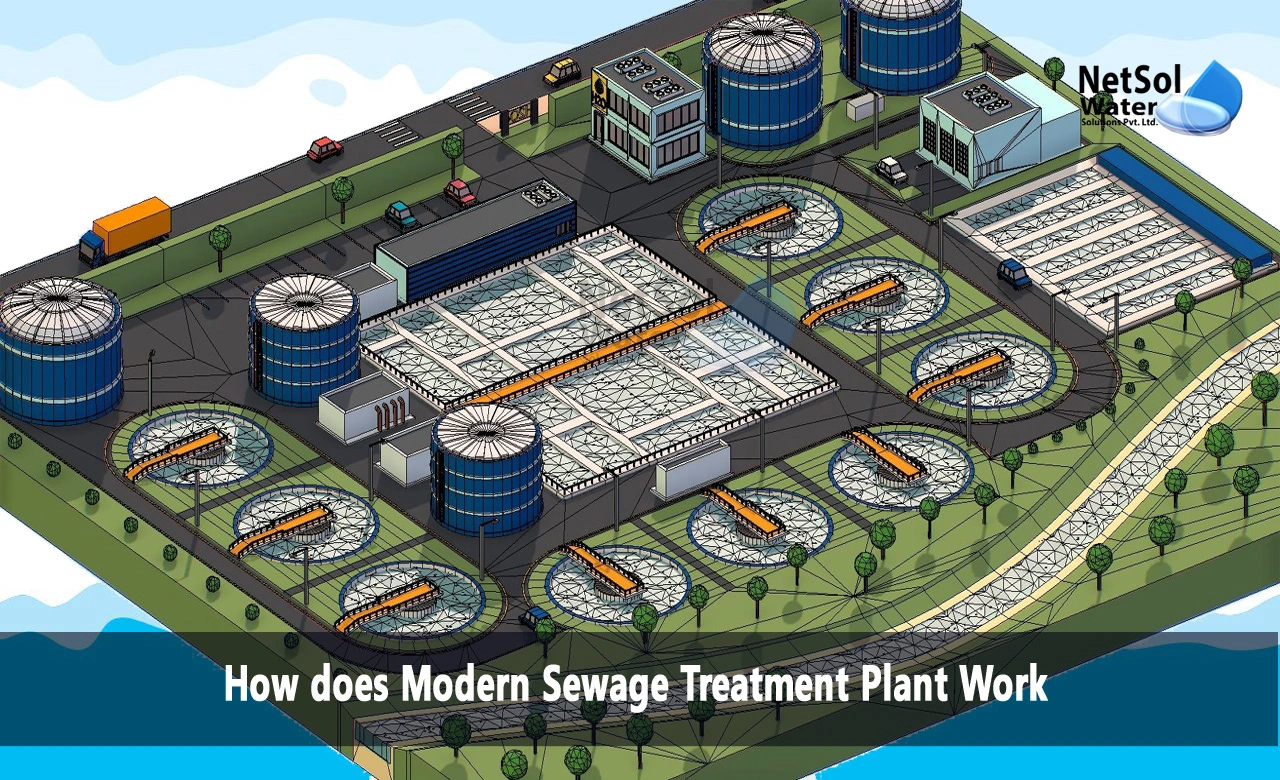

How does Modern Sewage Treatment Plant Work?

Sewage treatment is the process of removing contaminants from wastewater and household sewage, both runoff (effluents) and domestic. It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants to produce environmentally safe treated wastewater (or treated effluent). Modern sewage treatment plants are designed to dramatically reduce the pollution level of wastewater before it is released into the environment. This protects public health and the quality of surrounding bodies of water.

Overview of the Sewage Treatment Process

In general, sewage treatment involves three main phases: primary, secondary, and tertiary or advanced treatment.

Primary Treatment-

The first phase is known as primary treatment. This involves basic physical processes to remove solid materials from raw sewage:

Screening - Removes coarse materials such as wood, rags, sand and small plastic objects that could damage pumps and sewage lines. This is done by passing wastewater through bar screens.

Grit Removal - Sediments and gravel can settle out in a grit chamber. These heavier inorganic solids could also damage equipment if not removed.

Sedimentation - Wastewater flows into large sedimentation tanks, which allow suspended solids to settle to the bottom while greases and oils rise to the surface to form a scum layer. This is done in relatively quiescent conditions, allowing 1-2 hours of residence time.

The floating scum layer is skimmed off while the settled solids are removed for treatment or landfilled. This primary process typically removes 50-60% of suspended solids and 30% of organic matter in raw sewage.

Secondary Treatment-

After primary treatment, wastewater still contains high levels of organic matter (measured as biochemical oxygen demand or BOD) and suspended solids. Secondary treatment aims to substantially lower the BOD and total suspended solids (TSS).

The most common methods used globally are trickling filters and activated sludge systems:

Trickling Filters - Wastewater is sprayed over a bed of rocks, gravel, slag, or plastic media, allowing a biological film of bacteria and protozoa, which consumes organic matter, to develop. This forms a slime layer (biofilm) coating the filter media, which trickles down through the rocks under gravity.

Activated Sludge - Raw sewage is mixed with bacteria-rich sludge and agitated air, to promote breakdown of organic matter by aerobic microbes. This takes place in an aeration tank, producing activated sludge which is largely recycled to maximize the breakdown process.

Properly designed secondary treatment can remove 85-95% of BOD and TSS, achieving very high effluent quality before it passes to the next treatment phases.

Tertiary or Advanced Treatment -

Where especially high-quality effluent is required before discharge into rivers, lakes or oceans, additional tertiary (or advanced) treatments can be applied:

Nutrient Removal - High nutrient levels can trigger excessive growth of algae and aquatic plants in eutrophication, which imbalances ecosystems. Removing nitrogen and phosphorus minimises this.

Disinfection - Chlorine, ozone, or UV irradiation kills nearly all microorganisms in treated wastewater before their final release into the environment. Health risks from waterborne diseases are significantly reduced.

Filtration - Passing effluent through granular media filters like sand, anthracite and membrane filters removes almost all suspended particles and colloidal material.

Tertiary processes produce exceptionally clean final effluent, suitable for irrigation, groundwater recharge or industrial use where potable water quality is not essential. Sewage can thus be converted from a problematic waste into a valuable resource.

Innovations in Sewage Treatment Technology

Many innovative new processes are being developed and integrated into modern treatment plants to enhance efficiency, reduce operating costs and energy use, or to improve sludge treatment:

Membrane Bioreactors (MBRs) combine activated sludge and membrane filtration in a compact footprint, giving high-quality output.

Moving Bed Biofilm Reactors (MBBRs) are compact and highly efficient, using small plastic carrier elements to grow biofilm microorganisms. No secondary settling tanks are needed.

Anaerobic Digestion breaks down sludge without oxygen, producing methane gas, which can be used on-site as an energy source. This makes plants energy neutral or even energy positive.

Advanced Oxidation Processes (AOPs) involve oxidising chemicals like ozone and hydrogen peroxide under UV light to destroy trace organic compounds and drug residues.

Conclusion

With growing environmental awareness and regulations, modern sewage treatment has become incredibly effective at removing contaminants from vast volumes of wastewater. Using ever-improving technology, current plants can convert polluting sewage into squeaky-clean flows that are safe to return to nature or reuse in agriculture and industry. This allows us to offset potable water demand while restoring and protecting ecosystem health. Widespread adoption of advanced processes will be crucial as populations grow and the pressures on our limited water resources continue to intensify globally.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com