What are Circular Thickeners for Sludge processing?

Between upstream process screens, clarifiers, and separators and downstream dewatering and sludge conditioning operations, circular thickeners provide an important treatment step. A well-designed thickening provides storage and equalization, reduces sludge stream volume, and boosts solids concentrations. This enables more cost-effective dewatering and sludge conditioning systems to be developed, lowering both capital and operating expenses.

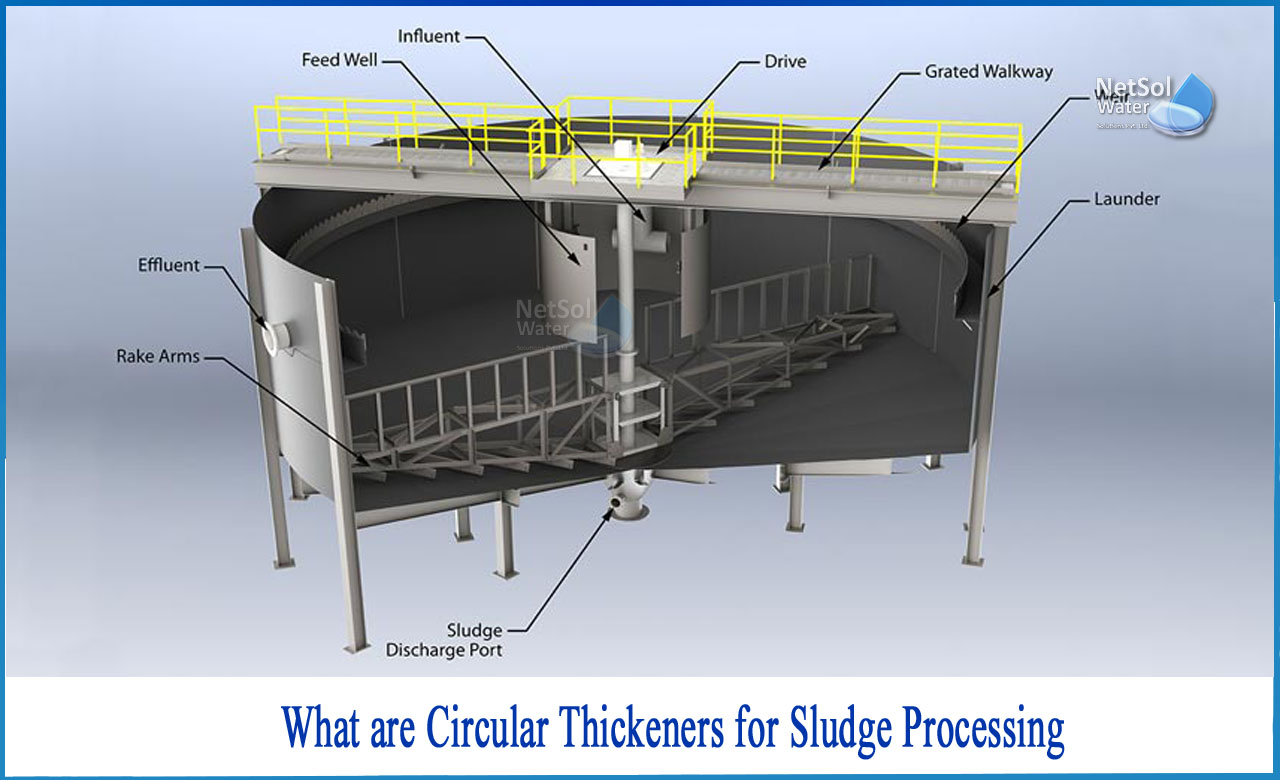

Thickeners resemble other clarifiers in appearance and operation, but they are employed to accomplish distinct goals and are situated at a different stage in the overall water/wastewater treatment process.

Working of Circular Sludge Thickeners

Thickeners take waste streams from screens, clarifiers, separators, and other water treatment processes and concentrate the sludge further. Solids contents in the incoming water range from 0 to 3 percent. Thickened solids concentrations are normally between 3–6%, however depending on process circumstances, higher concentrations can be attained.

Municipal water and wastewater treatment plants, steel mills, refineries, chemical plants, power plants, and most manufacturing plants with wastewater treatment equipment’s all use circular thickeners.

Applicationof Circular Sludge Thickeners

1: Sludge from municipal wastewater

2: Sludge from industrial wastewater

Advantagesof Circular Sludge Thickeners

1: Extremely low energy

2: Dewatering in a single step to 0.2 to 18 percent DS without pre-thickening

3: Sludge thickening technology that is widely utilized and accepted

Sludge collecting systems in circular thickeners

Due to the nature of the materials handled, circular thickeners require higher torque ratings than other clarifiers. Higher sludge densities and loadings necessitate more robust collection systems that can withstand the abrasive, heavy sludge.

-Netsol Water use a long-lasting high-torque motors and bottom scraping rakes to remove hardened sludge on a continuous basis. The rake has many bottom scraping blades that are geared to gather and transport all settling sludge to the central sludge hole.

-When the qualities of the sludge require more mechanical agitation, thickening pickets and drive lift mechanisms are frequently used.

-A thickening design package can include sludge level detectors, underflow pumps, and related piping and instrumentation.

Scum removal and skimmingin circular thickeners

1: Floating debris in thickening applications can include grease, oils, leaves, plastics, scum, and foam, among other things.

2: Floating matter is typically skimmed by a skimmer arm, which is supported by the sludge rake and revolves around the tank with it. The wipers on the skimmer arm push the floating matter over the beach plate and into a scum box attached to the tank wall. The scum exit piping receives the collected material. Anti-rotational scum baffles, ducking skimmers, and full radius collection troughs are among the other options.

What else can we offer?

Netsol Water is a renowned water and wastewater treatment plant manufacturer based in Greater Noida.

Based on client feedback and work quality, we are the most demanding organization in the water and wastewater industry. We have a reputation for being the TOP Commercial RO plant, Industrial RO plant, Sewage treatment plant, and Effluent treatment plant manufacturers.