Introduction

Any business that generates wastewater, which must afterwards be treated, can gain from a moving bed biofilm reactor (MBBR) method. A moving bed biofilm reactor is a biological method for treating sewage, that has several distinct advantages over more conventional approaches, like activated sludge or trickling filters. When it comes to elements like comfort, effectiveness, and adaptability, MBBR excels.

This article will take a comprehensive look at the MBBR process, describing how it works.

In contrast to chemical or mechanical processes, MBBR is a biological one. Here is a detailed explanation of the traits of a biological process.

Biological treatment of wastewater

Small creatures like bacteria or nematodes, are used in biological water treatment techniques, to assist in the decomposition of waste. Think about all the organic material in wastewater. To break down this waste, biological processes rely on cellular processes that occur naturally.

As certain microbes break down and consume the waste they come into contact with, adding them to the wastewater enables nature to take its course. Complex waste compounds in the water can be broken down by microbes into simpler materials, which can subsequently be filtered out through additional treatment.

How do MBBR systems work?

- Reactor, aeration tank, or basin

The MBBR process is carried out in an aeration tank or a reactor. The size of this container is determined by the plant's requirements for filtration. Influent enters this basin for treatment, and it might also enter another basin for more MBBR processing, or for a different kind of water treatment process. Since the top of MBBR aeration tanks is open, the water is exposed to the atmosphere, making this a process of aerobic filtering.

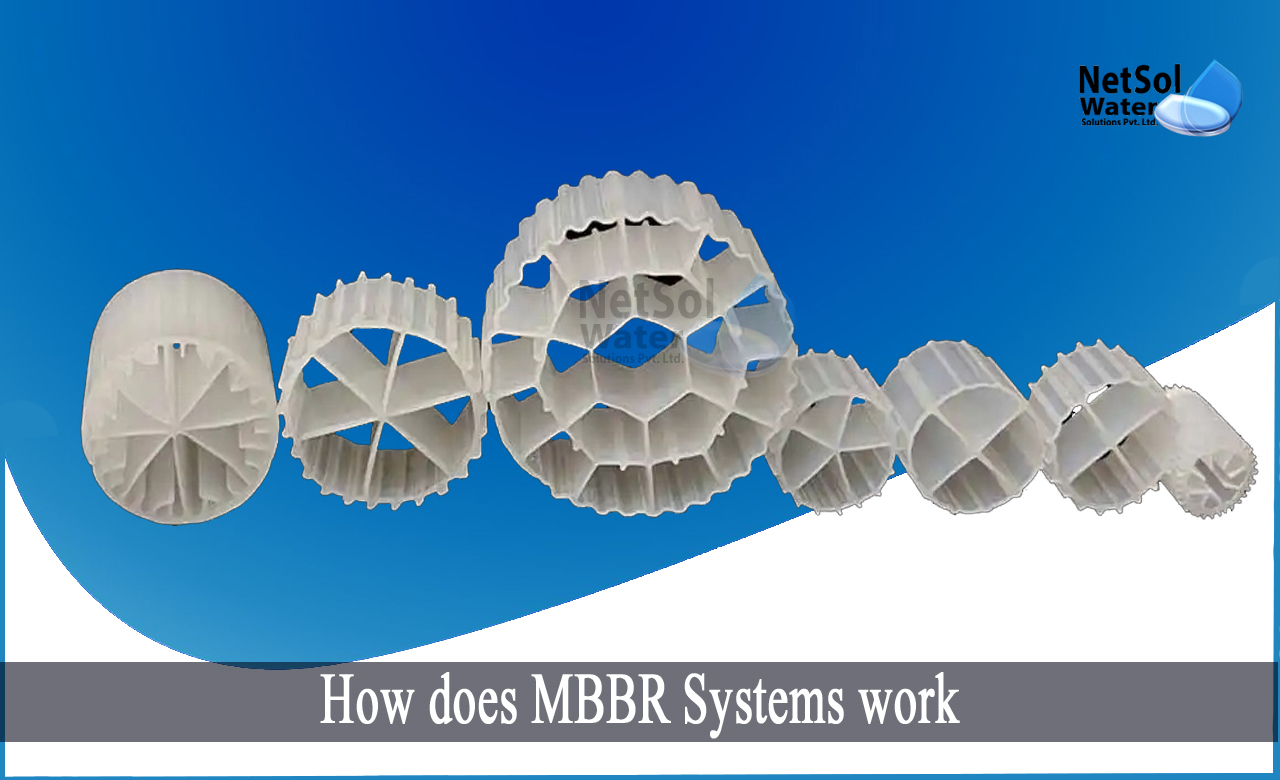

- Media or carriers

Numerous thousands of tiny plastic chips, also known as media or carriers, are piled up in the basin. These materials might take up between 50 and 70 percent of the tank. The surface area they offer for biofilm to grow on, is maximized by their design. Instead of floating or sinking, they are able to mix throughout the fluid, because they imitate the density of water.The plastic carriers are kept inside the basin by the mesh material, which allows water to pass through.

- Aeration grid

An aeration grid is another device that facilitates efficient media movement, throughout the tank. This component, which is found at the base of the reactor tank, is effectively a fan.

The aeration grid increases the amount of oxygen in the tank, and keeps carriers moving so they can effectively contact all of the waste, which is present, and degrade it.

- Disposal of wastewater

The water in the tank becomes cleaner and safer for re-use or disposal, after the microorganisms connected to the tank's medium devour waste. The kind of microorganisms added to the tank will vary, depending on the kind of waste that needs to be removed.

Additional features of MBBR Systems: Nitrification & denitrification

MBBR contributes to nitrification and denitrification. Denitrification happens when oxygen is digested, and nitrate converts into nitrogen gas. Nitrification is the process of turning ammonium into nitrate. Both of these processes are biological, thus MBBR is a great approach to support them.

The objectives of the MBBR process will determine the kinds of microorganisms that are added. For example, it is ideal to use denitrifiers, like Pseudomonas, Paracoccus, or Alcaligines in denitrification.

Netsol’s MBBR Systems and Services

For services related to MBBR, Netsol Water is a leading provider of technologically sophisticated wastewater treatment solutions. We are professionals at providing our valued clients with the highest-quality MBBR systems, and integrating them into their new and current facilities, as needed. For more automation and more effective treatment, our premium MBBR systems are designed, and produced in-house.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.