Membrane filtration is a separation process in which a liquid is separated into two streams by means of a semi-permeable membrane. The two streams are called retained and permeate. In the respective application, the specified components are either concentrated or removed/reduced. Basically, Membrane Filtration can be divided into four main technologies- ultrafiltration, Microfiltration,nanofiltration and Reverse osmosis

A modern dairy concentrates whey proteins by ultrafiltration. The permeate stream can be demineralized with a nanofiltration membrane that concentrates the lactose and leaves salts in the permeate. Finally, the dairy uses RO to concentrate the desired product stream. As a result, many membrane elements are already installed, for example in dairies, but whether for replacement or new installation. Reverse osmosis filtration technology is often used in dairies to remove water from milk for use in other processes such as cheese or milk powder. However, many resources would be saved if this process could be transferred to farms, as the amount of transported water would be reduced.

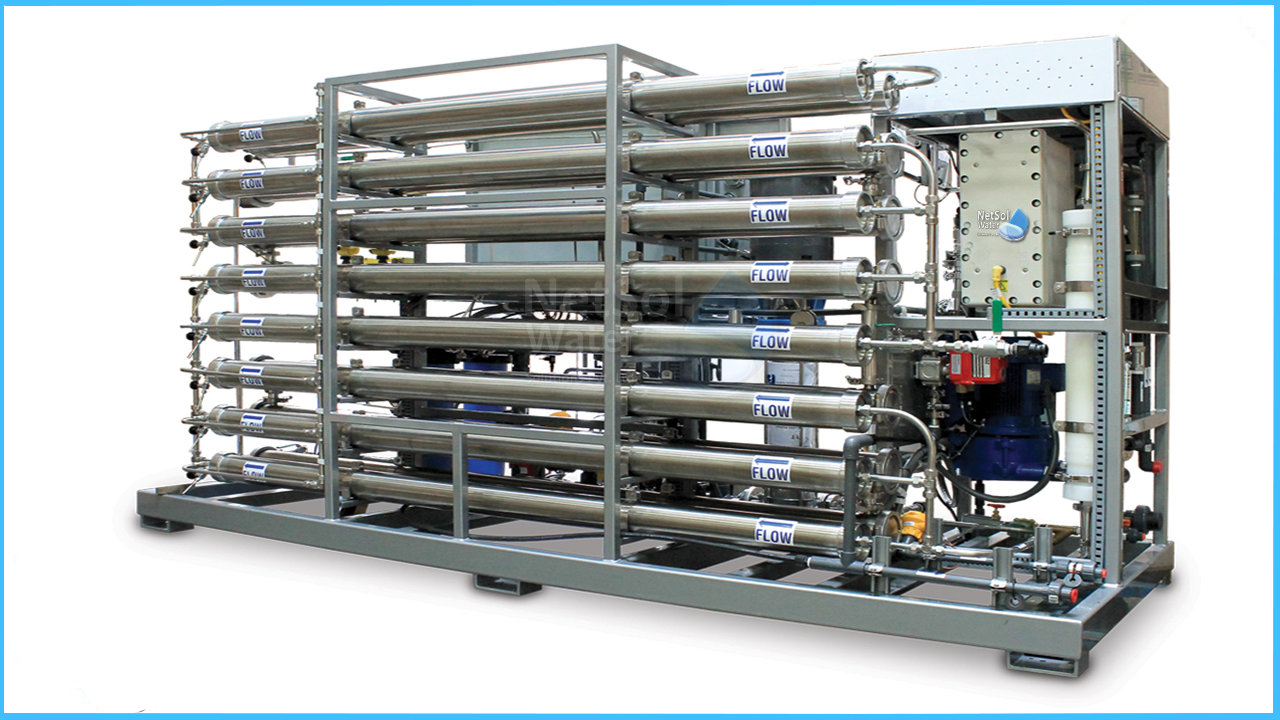

Reverse osmosis can be used as a complement to evaporation. If a new evaporation line is required or if an existing line is to be expanded, considerable savings can be achieved by combining the two technologies. Reverse osmosis is a very effective way to remove water from milk or whey before the evaporation phase. By installing a reverse osmosis system versus an existing evaporator, the performance of the evaporator can be greatly increased.

ADVANTAGES OF REVERSE OSMOSIS SYSTEM

- 1. Concentration

Reverse Osmosis can be used to concentrate skim milk or whole milk to increase total solids. This is also relevant for fermented products. Since reverse osmosis only removes water, the technology can be used as an energy efficient alternative to evaporation or the addition of powdered milk. These are the most common methods to increase the total solids in milk.

- 2, Volume reduction

Reverse osmosis can be used to reduce the volume of milk or whey and it can save transportation costs. An alternative to nanofiltration is reverse osmosis-based bulk reduction.

- 3. Recycling of products

For a modern dairy farm to meet the economic and ecological requirements of the surrounding society, recycling waste is increasingly important. From the first clean rinse, the “white water” is collected in a special collection tank. The fresh "white water" is concentrated to the required total solids content using reverse osmosis and the obtained solids can be reintroduced into the production process, for, e.g., Increase total solids in yogurt milk.

- 4. Water recovery

Permeate from reverse osmosis or nanofiltration processes and evaporator condensates are practically water. With an additional reverse osmosis treatment, generally called "polishing," this water can be purified and reused for cleaning purposes. With additional heat treatment or UV light treatment, it is even possible to use the water as process water.

- 5. Wastewater control

Some production plants, such aslarge whey processing plants have excess water that must be drained. Since water disposal is normally associated with emission taxes, subjecting water to reverse osmosis can reduce COD and those taxes.

Spiral wound reverse osmosis and nanofiltration elements have been critical technologies in dairy ingredient manufacturing for over thirty years. While some streams were considered dairy waste 30-40 years ago, technological innovations have made it possible to turn these streams into valuable products. This has led to a growing market demand for products such as whey protein concentrate and whey protein isolate. Over the years, innovations in filtration systems have changed the scenario for dairy industry as well.

Almost all the dairy product manufacturing processes contain membrane filtration or Reverse osmosis process.Whole milk, skim milk , cheese , whey all these dairy products manufacturing process can inculcate reverse osmosis system for its easy operation.