How Does an Effluent Treatment Plant Work?

Effluent treatment plants preserve our ecosystem. They clean wastewater from homes businesses and enterprises before releasing it back into nature. Without treatment pollutants and hazardous substances would infiltrate our rivers lakes and oceans. This would harm aquatic life, ruin ecosystems and threaten human health.

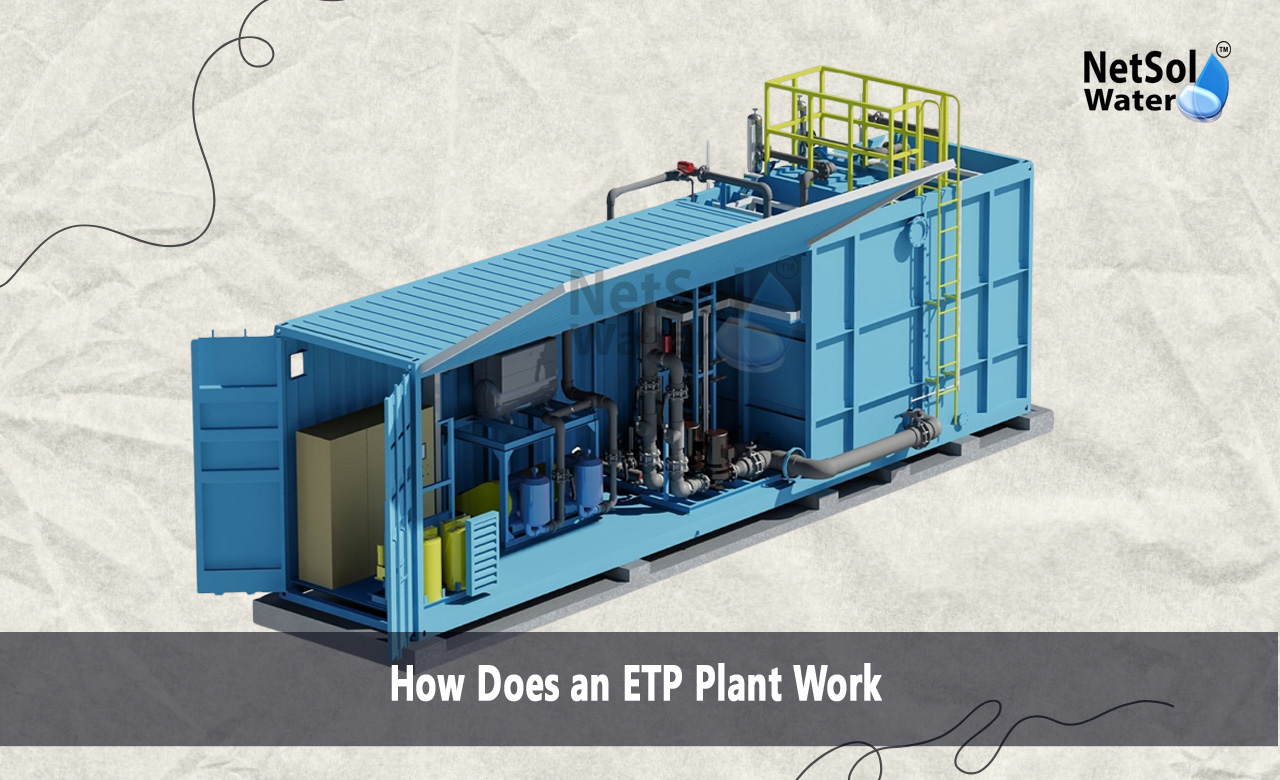

Treating wastewater comprises numerous processes. Each stage removes different pollutants. Effluent treatment plants filter water from big debris to microscopic contaminants. They utilize physical chemical and biological approaches. The technique seeks to generate water safe for disposal into the environment.

Everyone should know how these plants function. This awareness helps us value the effort to protect our water supplies. It can also inspire us to think carefully about what we dump down our drains. Learning about wastewater treatment enables us to contribute to a cleaner healthier earth.

This blog discusses how an effluent treatment plant works. We'll go to the process step by step.

The Stages of Effluent Treatment

Effluent treatment plants clean wastewater through a variety of processes. Each stage addresses certain contaminants. Let's investigate these steps in detail.

Preliminary Treatment

Preliminary treatment starts the procedure. This stage eliminates big items from the wastewater.

- Screening: Large screens trap plastic bags sticks and other trash.

- Grit Removal: Special chambers allow sand gravel and other heavy particles to settle.

This level protects equipment in later phases. It stops obstructions and saves damage to pumps and pipes.

Primary Treatment

Primary treatment follows preliminary treatment. This stage handles tiny particles that passed through before.

- Sedimentation: Large tanks store the water. Heavier particles sink generating sludge.

- Skimming: Oils and greases float to the surface. Machines skim them off the top.

This stage eliminates numerous suspended solids. It boosts the effectiveness of later stages.

Secondary Treatment

Secondary treatment uses biological mechanisms. This step targets dissolved and organic contaminants.

- Aeration: Pumps add air to the water. This grows beneficial bacteria.

- Bacterial Action: These bacteria break down organic materials.

- Clarification: More settling tanks remove any remaining solids.

This stage dramatically improves water quality. It removes most organic pollutants.

Tertiary Treatment

Some plants add a tertiary treatment stage. This final procedure removes any residual contaminants.

- Filtration: Filters trap microscopic particles as water goes through.

- Disinfection: Chemicals or UV light destroy leftover bacteria.

Tertiary treatment generates high-quality water. Plants generally use it when they'll reuse the water or release it into delicate settings.

Advanced Treatment Technologies

Modern plants often use modern technologies. These strategies target specific pollutants or increase overall efficiency.

Membrane Bioreactors

Membrane bioreactors combine biological treatment with membrane filtration. They provide exceptionally clean water in less space than typical systems.

Nutrient Removal

Some plants eliminate excess nutrients like nitrogen and phosphorus. This reduces algae blooms in receiving waters.

Advanced Oxidation

This technique breaks down difficult contaminants using intense oxidizing agents. It acts on substances that resist other treatment procedures.

Sludge Treatment and Disposal

The treatment process yields sludge as a byproduct. This sludge needs careful management and disposal.

Thickening

The process starts by lowering the sludge's water content. This makes it easy to manage and process.

Stabilization

Bacteria break down organic materials in the sludge. This minimizes smells and makes the sludge safer.

Dewatering

Machines take additional water from the muck. This further lowers its volume.

Disposal or Reuse

Plants can use the resulting sludge in numerous ways:

- As fertilizer in agriculture

- For energy production by incineration

- In landfills

Proper sludge management ensures the overall performance of the treatment plant.

Monitoring and Control

Effluent treatment plants need regular monitoring and management. This ensures they work effectively and meet environmental regulations.

Continuous Testing

Operators evaluate the water at different treatment stages routinely. They check:

- pH levels

- Oxygen content

- Nutrient levels

- Harmful bacteria

Automated Systems

Many plants utilize computers to monitor and regulate treatment. These systems alter operations based on incoming wastewater quality.

Compliance Reporting

Treatment plants must disclose their performance to environmental bodies. This shows they meet all essential standards.

Now that you know how an effluent treatment plant works you can help. Here's how to contribute to cleaner water:

1. Think carefully about what you throw down drains. Don't flush dangerous chemicals or non-biodegradable materials.

2. Support initiatives to modernize and improve local wastewater treatment systems.

3. Tell people about the necessity of effective wastewater treatment.

4. Use water-saving techniques at home or work to lessen the burden on treatment plants.

Want to learn more about wastewater treatment plants or water quality in your area? Contact us. Our professionals can answer your queries. Let's work together for cleaner water and a healthy environment. Help conserve our water resources for future generations.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com