How do FRP Integrated Sewage Treatment Plants Work?

People have begun to make attempts to enhance the environment in a variety of ways as people's attention has shifted to environmental protection and the worsening of water pollution and scarcity of water resources.

The usage of sewage treatment technology is an efficient technique to reduce water contamination and increase sewage recycling rates. There are many processing equipment’s in the sewage treatment market, and the FRP integrated wastewater treatment equipment is one of them.

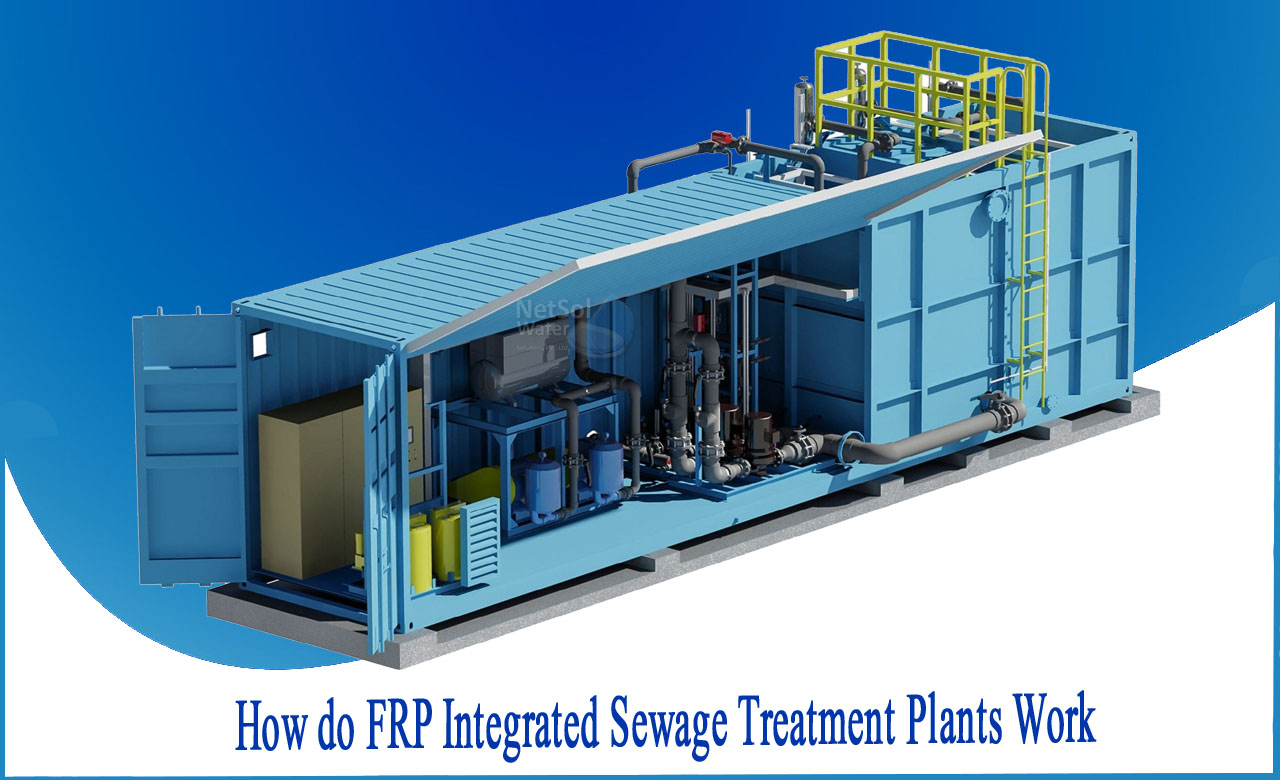

What are FRP integrated STPs?

The FRP integrated sewage treatment system is a relatively advanced sewage treatment equipment. These systems use the most advanced biological treatment process, BOD-5 elimination, COD elimination, and NH3-N removal.

Applications of FRP integrated STPs

The sewage treatment equipment is commonly employed in high-end hotels, villas, and residential areas. Field testing demonstrates that integrated sewage treatment equipment is an ideal and convenient management tool.

Removal of pollutants in FRP integrated STPs

The elimination of organic pollutants and ammonia nitrogen in FRP integrated sewage treatment equipment is primarily dependent on the device's biological treatment process.

1: Because of the high concentration of organic sewage, the microorganisms in this type of activity are facultative microorganisms, and they degrade organic wastewater in NH3-N while also using organic carbon as an electron donor to convert NO to N.

2: As a result, the primary pond not only performs biological activities, but it also reduces the organic burden of the later aerobic ponds. It is intended for nitrification and relies on the high concentration of organic matter in raw water to complete denitrification and reduce nitrogen eutrophication pollution.

3: Because of the large reduction of ammonia nitrogen at higher concentrations of organic matter, there is still some organic matter. Aerobic biological contact oxidation pools with moderate organic load are placed at a level to further oxidatively degrade organic waste while also proceeding smoothly under fully nitrified carbonation conditions.

4: Aerobic microorganisms and bacterial oxygen types predominate in this stage. These microorganisms degrade organic matter into CO2 and H2O and autotrophic bacteria absorb inorganic carbon from organic matter in the air as nutrients, or NH3-N generated by CO2.

Some of the key benefits of FRP integrated STPs are as follows:

1. Longevity and durability.

2. Economical Effectiveness.

3. Adaptability to Multiple Installation Methods - Underground & Above Ground.

4. There is little or no need for civil works on-site.

5. It has a smaller footprint.

6. These are modular pre-constructed systems.

7. It decrease the Carbon dioxide emissions in the surrounding environment.

8. It has semi-automatic controls.

9. It has low maintenance requirements.

10. It is easy to install, transport as well as relocate.

Conclusion

Fibre-Reinforced Plastics (FRP) are composite materials composed of fibres and polymers. When carefully planned and engineered, it is the finest choice of material for Sewage Treatment Plants (STPs) due to its cost effectiveness, durability, and extended lifetime.

What do we have to offer?

Netsol Water is a renowned producer of water and wastewater treatment plants. Based on client feedback and job quality, we are the most demanding organization in the water industry. We have a reputation for being the top commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, effluent treatment plant manufacturer, and much more. Aside from that, our USP is 24x7 customer assistance.