What is ASP or activated sludge process?

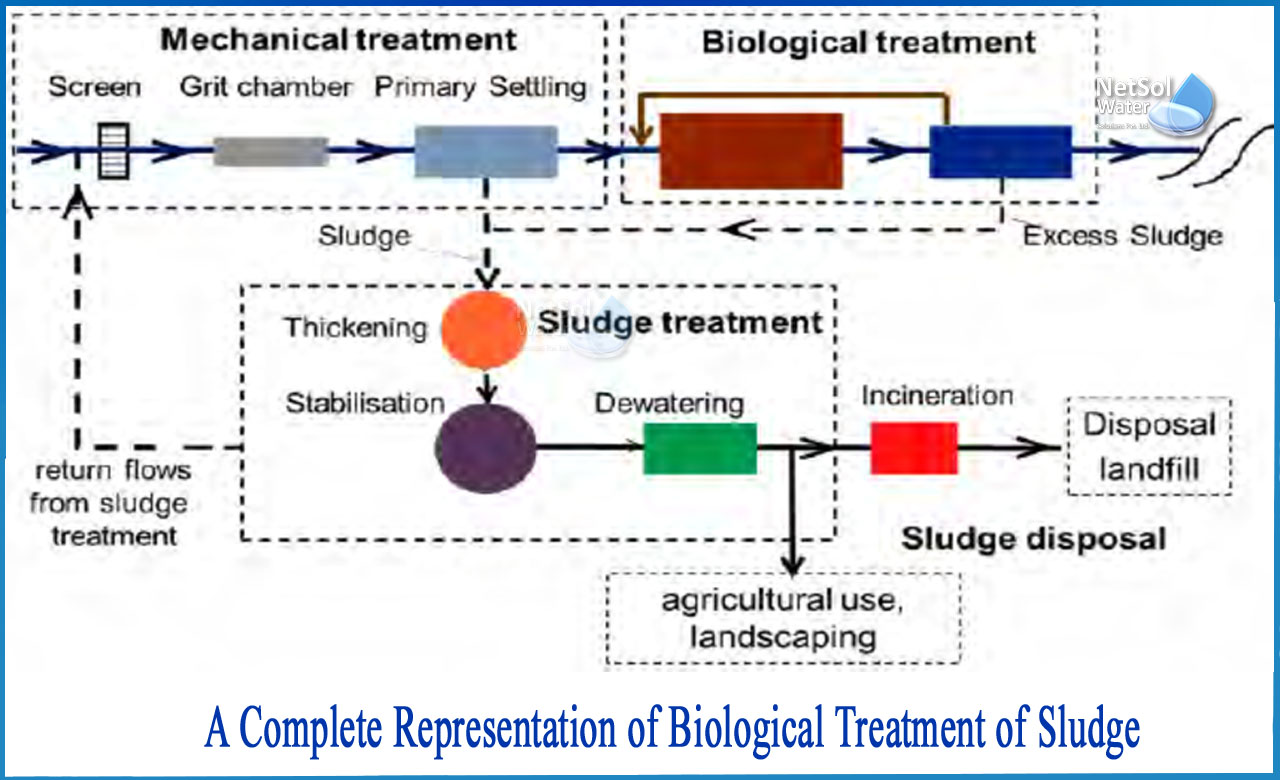

The activated sludge process is a biological procedure that converts non-settleable chemicals in dissolved and colloidal forms into settleable sludge that is then removed from the liquid carrier (water). The activated sludge, along with the suspended solids in the wastewater, is sorted out at a facility. Within the constraints of practical economy and current understanding of the art and science of waste treatment, the activated sludge method delivers one of the greatest degrees of treatment possible.

Working of ASP

In an aerobic (oxygen-containing) environment, groups of microorganisms, primarily bacteria, along with protozoan, fungi, and rotifers, are kept in touch with the organic content in the trash. For these microbes, several types of organic materials carried in wastewater serve as a food source.

What is MLSS?

Biological solids, also known as mixed liquid suspended solids, are the mass of microorganisms present in the system (MLSS). In the activated sludge system, MLSS refers to all suspended matter, including inert matter, non-biological organic matter, and active microorganisms. The breakdown of organic matter (measured by 5 day Biochemical Oxygen Demand – BOD-5), as well as the creation of cell mass (active sludge) and by-products, are the basic processes (carbon dioxide and water).

What is the goal of ASP?

The essential goal of the activated sludge system is to provide food (BOD-5) and a suitable environment for microorganisms to grow and maintain a viable population. Microorganisms in the right conditions convert soluble and colloidal material in wastewater into new cells (active sludge) and end products (CO2 and water).

Microorganisms go through a constant cycle of growth and decline throughout their lives.Because the plant will be in the endogenous phase, the amount of cell matter produced will be minimal, resulting in a minimal amount of extra sludge to be discarded. The activated sludge unit reaction is used to identify the real range of F/M values that will generate the best plant functioning. As a result, the F/M range to utilise is the one that generates sludge with good settling qualities while creating the least BOD-5 and suspended particles in the effluent.

The activated sludge will flocculate and settle nicely in the right F/M range, while BOD-5 removal through the plant will be at its optimum. Any variation from the proper F/M range will make operating and controlling the plant challenging.

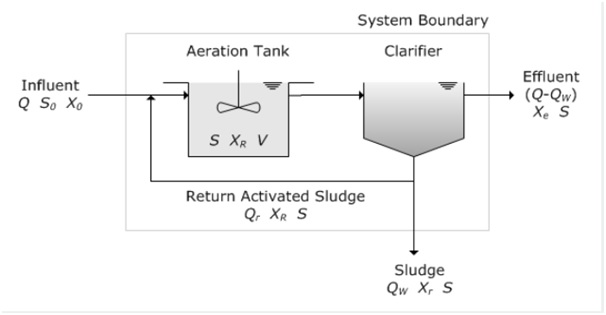

Diagram of the Activated-Sludge Process

BOD removal is a key aspect of municipal wastewater treatment. A biological technique, such as the suspended growth treatment process, is used to remove BOD. This is an aerobic biological process that occurs in the aeration tank, where the wastewater is aerated with oxygen. Bacteria will develop quickly if the right circumstances are created. Bacterial growth produces flocks and gases. A supplementary clarifier will remove these flocks.

A schematic diagram of an Activated-Sludge System.

This system is often installed between a municipal wastewater treatment plant's primary clarifier and disinfection. A Flow Diagram of a Municipal Wastewater Treatment Plant with a Suspended-Growth Process helps you understand the entire wastewater treatment process.

The symbols in the schematic diagram represent the parameters that are utilised to model a stalled growth phase.

Where:

|

Q = |

Flowrate of influent |

[m3/d] |

|

QW = |

Waste sludge flowrate |

[m3/d] |

|

Qr = |

Flowrate in return line from clarifier |

[m3/d] |

|

V = |

Volume of aeration tank |

[m3] |

|

S0 = |

Influent soluble substrate concentration (bsCOD) |

[BOD g/m3] or [bsCOD g/m3] |

|

S = |

Effluent soluble substrate concentration (bsCOD) |

[BOD g/m3] or [bsCOD g/m3] |

|

X0 = |

Concentration of biomass in influent |

[g VSS/m3] |

|

XR= |

Concentration of biomass in return line from clarifier |

[g VSS/m3] |

|

Xr = |

Concentration of biomass in sludge drain |

[g VSS/m3] |

|

Xe = |

Concentration of biomass in effluent |

[g VSS/m3] |

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.