How do Water Treatment Plants Clean Water?

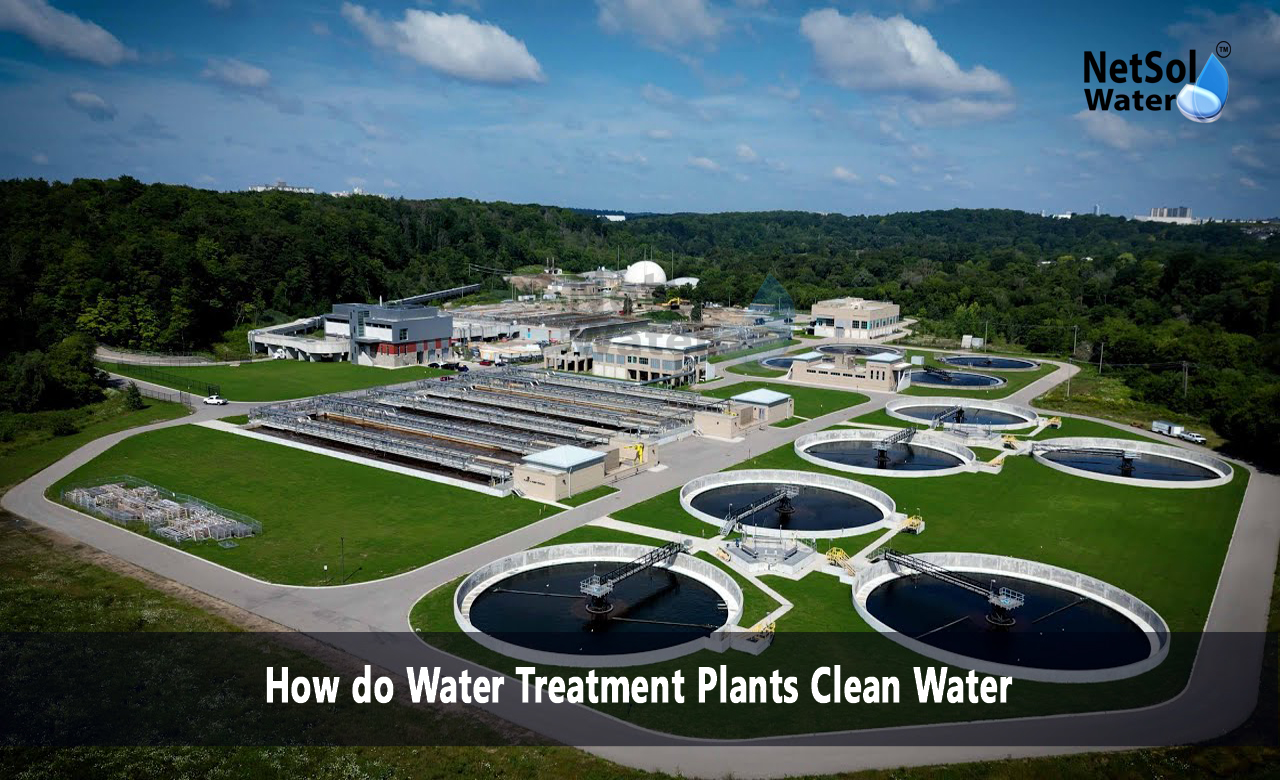

Water holds the key to life. The global challenge of accessing clean water persists. Water treatment plants form the backbone of modern society as they transform contaminated water into safe drinking water. These facilities adopt advanced processes to eliminate harmful substances. We will show you how water treatment plants, including effluent treatment plants and sewage treatment plants, work to deliver clean water to communities and industries.

Clean water shapes public health, industrial operations and environmental sustainability. Harmful bacteria, chemicals and other contaminants can trigger serious illness and harm ecosystems when water goes untreated. Water treatment plants employ specialized equipment and thoughtfully designed processes to address these risks. The facilities process thousands of gallons of water for homes, businesses and industrial facilities every day.

The need for clean water pushes innovation in treatment technology forward. Modern facilities now feature advanced filtration systems like industrial RO plants to achieve better purification. These advances in technology enable treatment plants to tackle new challenges from emerging contaminants. The complex journey water takes from source to tap unfolds as we examine how these facilities operate.

Primary Treatment - The First Stage of Water Purification

Primary treatment launches the water purification journey. The first step eliminates large particles and debris from incoming water. This process shields equipment from damage and enhances the success of later treatment stages. We will explore the key components that drive primary treatment forward.

Screening: Large screens capture items like sticks, leaves and trash when water enters the treatment facility. Several layers of finer screens trap smaller particles. The screening process guards pumps and other equipment from harm while enhancing water quality.

Sedimentation: Water flows to sedimentation tanks after screening. These spacious basins decrease water flow, enabling heavy particles to drop to the bottom. The settled material, known as sludge gathers at the tank base for extraction. The clearer water continues to the next treatment stage.

Flotation: Some contaminants rise instead of sink. Flotation systems push air bubbles that stick to these particles, pulling them up to the surface. Skimmers extract the floating material leaving purer water below. This step works with sedimentation to target various types of impurities.

Secondary Treatment - Biological Purification Process

Secondary treatment expands on primary treatment outcomes through biological processes. This stage focuses on dissolved contaminants that moved past initial screening. Natural processes transform harmful substances into harmless elements. The importance of biological activity in water purification becomes clear as we examine how secondary treatment works.

Activated Sludge Process: The activated sludge process employs beneficial bacteria to digest organic matter. These microorganisms found naturally in water break down contaminants. Treatment plants establish perfect conditions for bacterial growth in aeration tanks. The process copies nature's method of cleaning water at a faster rate.

Trickling Filters: Some facilities choose trickling filters over activated sludge. These systems direct water over beds of rock or plastic material. Beneficial bacteria develop on these surfaces, creating a biological film. The bacteria consume contaminants as water passes through. This approach uses less energy than activated sludge systems.

Rotating Biological Contactors: Some facilities implement rotating biological contactors (RBCs). These systems use large discs that sit partially in water. The rotating discs expose bacteria to both air and contaminated water. This creates optimal conditions for bacterial growth and contaminant removal.

Advanced Treatment - Modern Purification Technologies

Advanced treatment completes the water purification process. This phase uses sophisticated technologies to extract the remaining impurities. Commercial RO plants and industrial RO plants take centre stage in this phase. Modern treatment facilities merge multiple methods to reach the highest water quality standards.

Membrane Filtration: Advanced membrane systems power many RO plants. These systems implement specialized materials with microscopic pores to filter water. Each membrane type targets specific contaminants. This technology generates extremely pure water for industrial and commercial use.

UV Disinfection: Ultraviolet light offers chemical-free disinfection. Special lamps generate UV rays to destroy harmful microorganisms. This method eliminates chemical additives. UV treatment partners with other purification methods to guarantee water safety.

Ion Exchange: Ion exchange systems extract dissolved minerals and other charged particles. This process transforms hard water into soft water and removes specific contaminants. Both municipal and industrial applications benefit from this technology. Ion exchange enhances RO systems in many treatment plants.

Conclusion:

Clean water fuels life, drives industry and safeguards public health. Water treatment plants convert contaminated water into a safe resource through multiple purification stages. These facilities ensure water meets strict quality standards from initial screening to advanced membrane filtration. The blend of traditional methods and modern technology in effluent treatment plants produces effective water purification solutions.

Do you want expert guidance on water treatment solutions? Our team will show you how our advanced treatment systems, including commercial RO plants can address your needs. We offer tailored solutions for residential, commercial and industrial applications.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com