How do Water Softeners function for boilers?

One of the most common causes of poor boiler performance is improper water treatment. Scaling, or long-term boiler tube damage, can be caused by poor water treatment or failing to treat your boiler water at all. To avoid scaling, boiler water should be routed through a water softener before being given to the boiler.

It's vital to keep your boiler supplied with soft water at all times to avoid damage and costly repairs. When water softening is combined with a dependable water treatment chemical program and blowdown schedule, boiler system performance can be assured for many years.

What is a water softener?

A water softener is one of the most significant boiler accessories you may have, as it performs a variety of functions. Water softeners in boilers play an important role in preventing boiler problems and allowing them to run more efficiently. Foreign particles such as magnesium, calcium, and other hard minerals are removed by a water softener. These particles adhere to the boiler's inner liner, diminishing heat transfer efficiency, increasing the amount of energy required by your boiler, and triggering problems.

Let's start from the beginning and look at how water softeners are utilized in boilers!

Working of water softeners

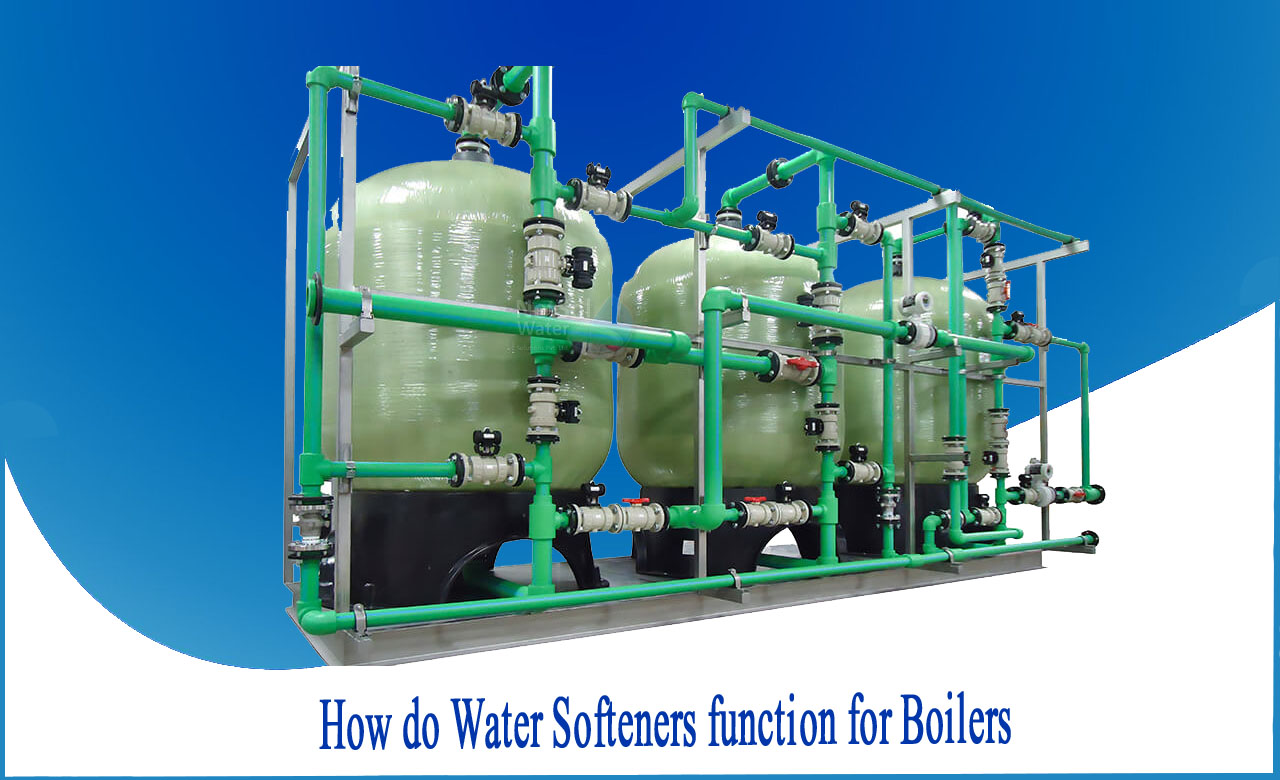

Water softeners are ion exchangers that are used to remove positively charged ions from water. A cation exchange resin-filled pressure vessel makes up a water softener.

1: As the hard water travels through the resin, adsorption occurs on its surface. Resin adsorbs calcium and magnesium ions and produces sodium ions, which are not hard. The resin beads must be cleaned during regeneration cycles in order for the system to continue to remove hardness from the water supply.

2: The regeneration procedure involves washing away the particles, pulling brine from the brine tank, and recharging the resin beads, which can take one to two hours. The boiler will be supplied with hard water during the regeneration process if your softener only has one resin tank.

3: In a two-tank system, the backup resin tank will become active during the regeneration of the first tank, allowing soft water to continue to flow to the boiler.

Why water softeners are used for boilers?

Water softeners are a standard piece of pre-treatment equipment. Water that is too hard scales up inside a boiler, lowering heat exchange efficiency and eventually damaging the boiler.

The use of water softeners reduces or eliminates the need for chemical treatments to keep boilers clean. A boiler's efficiency will inevitably deteriorate as it is used. Boilers that are inefficient cost more in terms of electricity, gas, and maintenance.

One of the most common causes of poor boiler performance is improper water treatment. Any boiler maintenance procedure must include treatment. A water softener can help keep your boiler in a good working order as part of your routine maintenance.

Conclusion

Only soft water should be used in your boiler. It's not a question of if, but when, your boiler will require repairs and maintenance if you don't operate it properly. A water softener is essential for keeping your boiler in good working order so that you can get the most out of it.

What can we offer?

Netsol Water, as water treatment experts, can help you with water reuse and conservation in your operations, as well as the optimization of existing water production and the design and building of new, energy-efficient, and environmentally friendly water treatment systems like Water Softeners. Our products and solutions can provide the water your plant requires at every stage!

Let us know your problem, our experts will make sure that it goes away!