What are boilers and its types?

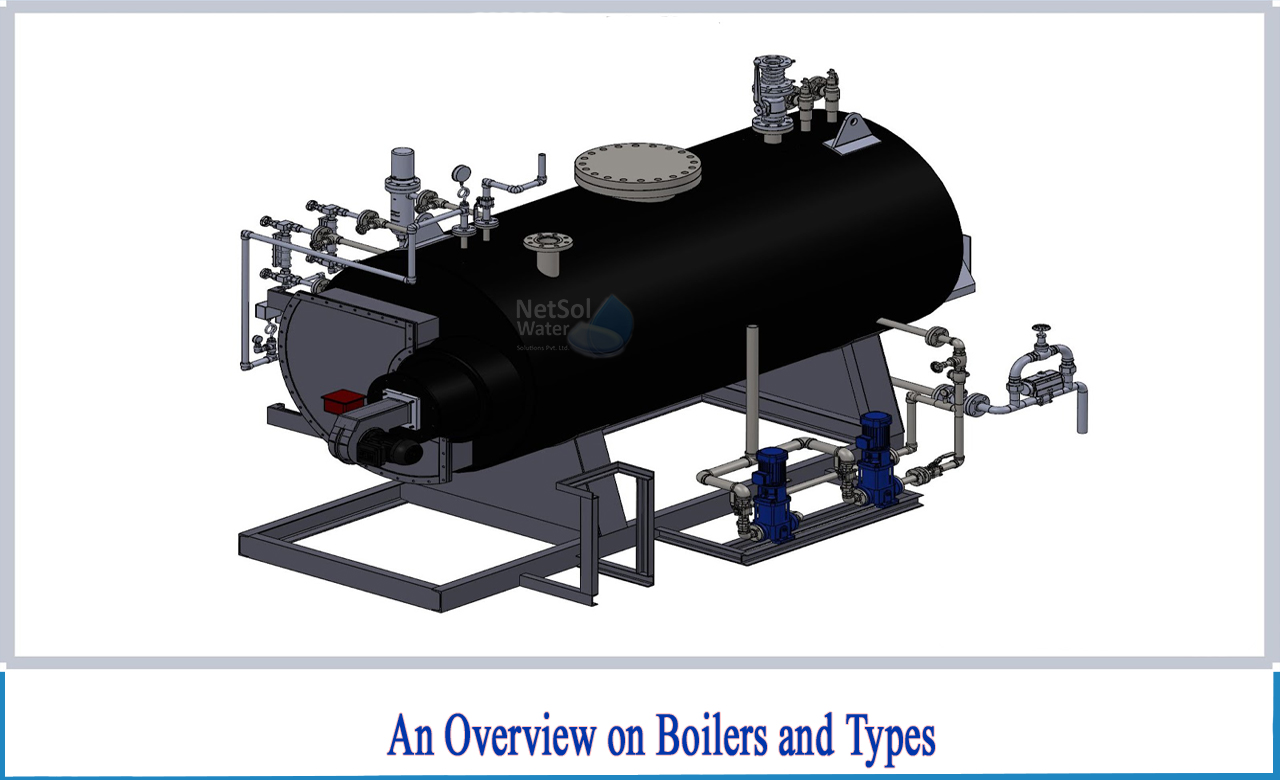

Boilers and steam production are necessary in today's world. From generating electricity to heating buildings and everything in between, boilers are employed in practically every industry. Boilers come in a variety of styles and sizes to meet the varying demands for steam production.

1-Firetube Boilers:

In an industry, firetube boilers are the most popular form of boiler. Hot combustion gases travel through the boiler tubes in a firetube boiler, while water is on the exterior of the tubes. Before being evacuated through the flue stack, the hot combustion gases normally travel through the vessel three or four times.Thermal conduction, convection, and radiation move the heat from combustion through the tube walls, heating the water and eventually creating steam. A firetube boiler's highest capacity is normally 2,000 horsepower.

[1 boiler horse power (BHP) produces 34.5 pounds of steam per hour].

Pressures in firetube boilers typically do not exceed 350 psig.

2-Water tube Boilers:

Large businesses such as power generation, petrochemicals, and oil refining use watertube boilers. The water circulates inside the tubes of a watertube boiler and is heated by the combustion gases on the outside. The fuel is burned in the boiler's furnace portion. Natural gas, coal, biomass, and other solid fuels can all be used in watertube boilers. The heated water flows up the riser tubes (also known as generating tubes) to the steam drum as it is heated in the tubes.

The steam is extracted from the top of the steam drum, separated from the water, and delivered into the process. Downcomer tubes return cooler water from the bottom of the steam drum to the mud drum. The steam drum is injected with feedwater, which is then heated to steam pressure and temperature.

3-Hybrid Boiler:

Hybrid Boilers are a type of boiler that combines the advantages of both. TheHybrid boiler is another frequent type of boiler seen in industry. A hybrid boiler incorporates elements of both a watertube and a firetube boiler to provide the best of both worlds.

Saw mills and other facilities with an availability of biomass or hog fuel for an economical fuel supply frequently employ hybrid boilers.The hybrid boiler's watertube section is similar to that of an A-Type boiler. The tubes in the boiler's watertube section are sometimes referred to as "Chapel Tubes." The water goes up the Chapel tubes after being heated by biomass fuels used in the boiler's furnace section. The heated water from the boiler's watertube section is routed to the body of the firetube section, while steam is drawn from the top drum into the firetube section's steam chamber.

4-Vertical Boilers:

Vertical boilers are becoming more popular as a result of their small footprint, low initial start -up cost, and high steaming rates. Small hospitals, operation centres, and bakeries frequently use vertical boilers. Vertical boilers typically operate at a maximum pressure of 15 psig and have a steaming capacity of 50 horsepower. Vertical boilers are prone to carryover due to their narrow steam area. Elevated oxygen scavenger residuals are necessary to protect the vertical boiler from oxygen assault. It's vital to prevent precipitating internal treatments in vertical boilers because of their single tube construction. Treatment regimens for polymers must be used. In vertical boilers, a consistent soft water feed is essential for maintaining clean heat exchange surfaces.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.