Introduction to UASB reactor

The Upflow Anaerobic Sludge Blanket reactor also known as UASB reactor is an anaerobic methane-producing digester that creates a blanket of granular sludge that is digested by anaerobic bacteria. UASB reactor is a modified version of the contact anaerobic process which is used in wastewater treatment based on an upward movement of the liquid waste through a dense blanket of anaerobic sludge.The biomass grows on the fine sludge particles, which ultimately evolves into high-specific-gravity sludge granules.

Although wastewater containing high suspended solid is successfully treated in UASB reactor, pre-treatment such as sedimentation, neutralization of wastewater is normally desirable in treating wastewater in UASB reactor. Organic loading in the range of 1-20kg COD/m3.day can be applied with removal efficiency of 75-85% and HRT of 4 to 24hours.

Parts/Componentsof UASB Reactor

The UASB reactor can be divided in three main parts:

a) Sludge bed,

b) Sludge blanket, and

c) Three phase separator (gas-liquid-solid, GLS separator) provided at the top of the reactor.

Under high turbulence, the three-phase separator allows the reactor to separate gas, water, and sludge mixtures.

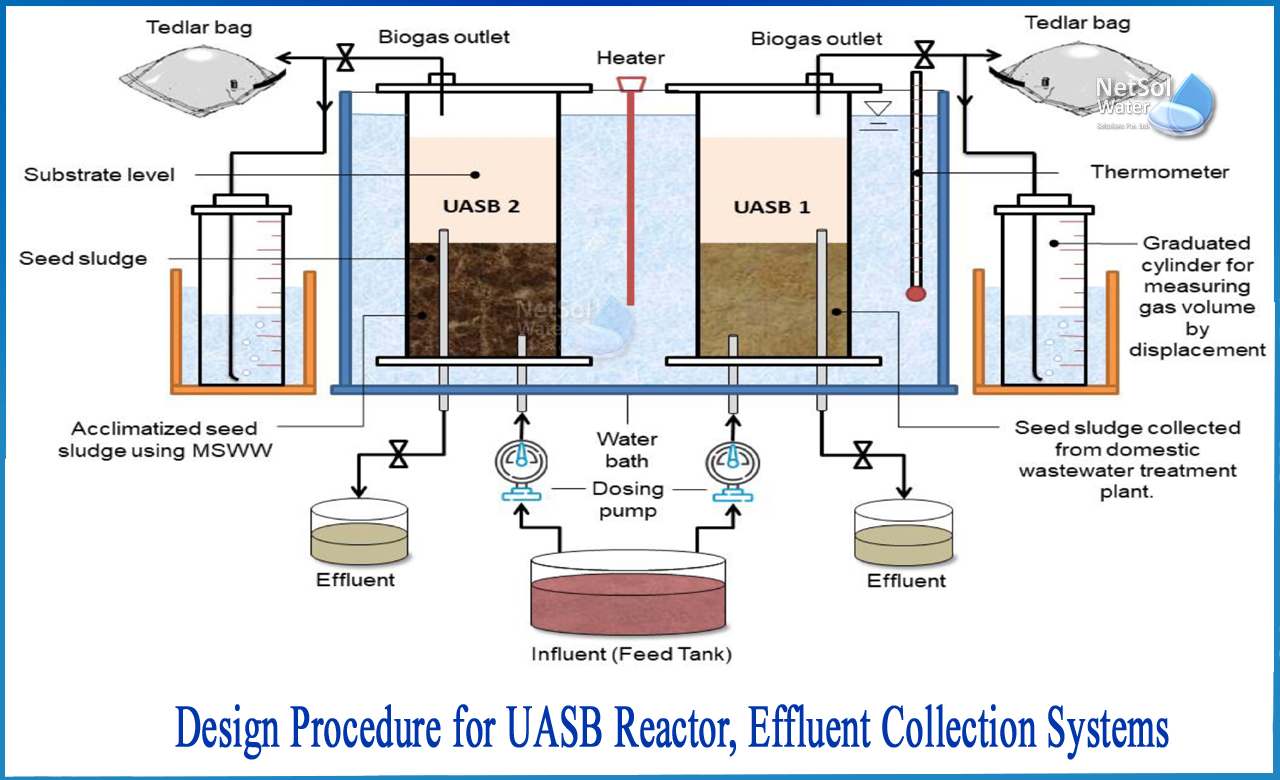

How to Design a UASB reactor for Effluent collection systems?

UASB reactor consists of a tank designed as circular or rectangular, where the wastewater flows upwards through a dense sludge bed with high anaerobic microbial activity. The sludge bed occupies about half the volume of the reactor and consists of microbial granules (1 to 3 mm in diameter) or highly sedimentable flocs. The sludge is mixed by rising bubbles without the use of any mechanical equipment. The cleared effluent is taken from the tank's top, above the sloped walls. The solids profile in the reactor varies from very dense and granular particles close to the bottom to more dispersed and light particles close to the top.It is necessary to select proper range of operating parameters for design such as organic concentration, superficial liquid upflow velocity, reactor volume, effluent collection system, design of feed inlet system, hydraulic retention time, etc.

In this article we will discuss the literature recommendation for effluent collection system and design of feed inlet system.

Effluent collection system

The effluent must exit the UASB reactor through a network of launders located throughout the facility, with the primary launder located at the reactor's periphery. The effluent launders can be constructed such that the weir loading (m3 /m.d) does not exceed the secondary settling tank design criterion (i.e. 185 m3 /m.d).

To make maintenance easier, the launders should be at least 0.20 m wide. Open channel flow may be used to calculate the depth of the wash. To enable free flow, an additional depth of 0.10 to 0.15 m should be supplied.

'V' notches must be utilized on both sides of the launders. When scum baffles are installed in effluent launders, the 'V' notches are protected from clogging because the baffles catch the floating materials. At the top of the reactor, a scum layer and sludge may form. As a result of the build-up that might form in the launder, it is necessary to clean the launders on a regular basis and remove the accumulation.

Insight on feed inlet system

It is critical to maintain optimal contact between the sludge accessible inside the reactor and the wastewater entered, as well as to avoid wastewater channeling through the sludge bed.

As a result, adequate intake distribution system design is required. Depending on topography, pumping arrangement, and the likelihood of inlet pipe blocking, either gravity feed from the top (preferred for wastewater with high suspended fraction) or pumped feed from the bottom through manifold and laterals (preferred for soluble industrial wastewaters) could be provided.

The blockage of the nozzles can be a severe issue, resulting in unequal results, particularly when processing partly soluble wastewater, dispersion of effluent across reactor bottom wastewater. As a result, plants for cleaning or flushing the inlet system should be made.

How can we assist?

Netsol Water is a pure-play technology company that offers a variety of wastewater-related solutions around the world, including resource conservation, optimization, recycling, and reuse.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.