What is a water softener?

The water softener reduces dissolved calcium, magnesium, and to some extent manganese and iron ions in hard water.

These "hardness ions" cause three major types of undesired effects.

>Metal ions most visibly react with soaps and calcium-sensitive cleaning agents, preventing foam formation and forming precipitates. This is the well-known "bathtub ring". The presence of "hardness ions" also impairs the cleaning effect of detergent formulations.

>Second, calcium carbonate and magnesium carbonate tend to settle as hard water deposits on the surface of the tube and the surface of the heat exchanger. This is principally caused by thermal decomposition of bicarbonate ions but also happens to some extent even in the absence of such ions. The resulting build-up of scale can restrict water flow in pipes. In boilers, the deposits act as an insulation that impairs the flow of heat into water, reducing the heating efficiency and allowing the metal boiler components to overheat. In a pressurized system, this can lead to failure of the boiler.

>Third, the presence of ions in an electrolyte, in this case, hard water, can also lead to galvanic corrosion, in which one metal will preferentially corrode when in contact with another type of metal, when both are in contact with an electrolyte. However the sodium (or Potassium) ions released during conventional water softening are much more electrolytically active than the Calcium or Magnesium ions that they replace and galvanic corrosion would be expected to be substantially increased by water softening and not decreased. Similarly, when using leads, soft water can be significantly more solvent-based than hard water.

What is a water softener resin?

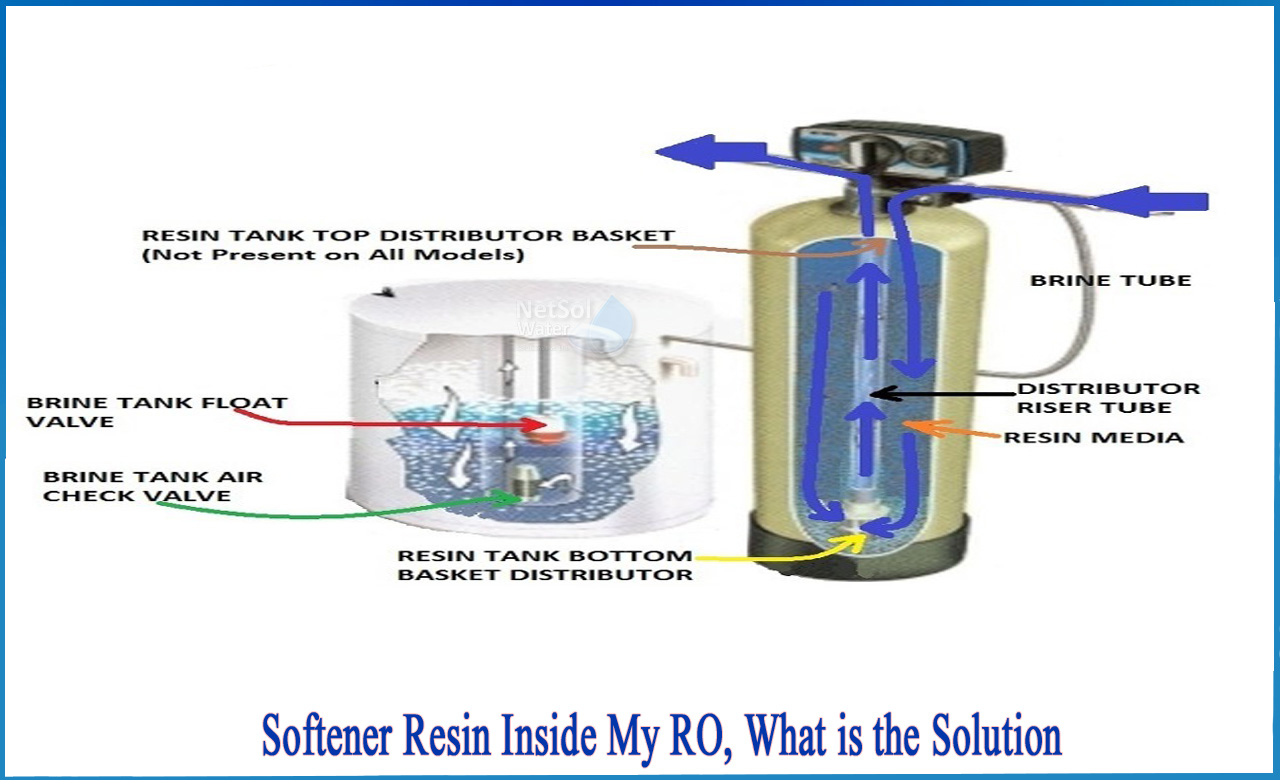

Basically, the resin or mineral in the mineral tank is specially designed to remove "hard" lime and calcium particles by a simple ion exchange process. The resin beads in the softening tank have a different or opposite charge to the dissolved particles of the inflowing water. Due to this difference in charge, the dissolved particles suspended in water attach to the resin beads upon contact, removing these particles from the water and "softening" the water leaving the device. Resin has a limit on how much these hardness particles can be absorbed. Therefore, plasticizers come in a variety of sizes and also require regeneration or brine.

Recently, there has been issues regarding the quality and pressure issues of the reverse osmosis system. Investigation revealed that the RO system contained resin and these resins came from the installed softener systems.

In such a case, an internal piping or the lower manifold of the water softener is broken.

Why is the line inside broken?

This can be done in several different ways, but the two most common methods are:

1.) Media mounting: It is advisable to take some time when placing the plasticizer gravel under the bedding. Before adding gravel, it is advisable to fill the soft water tank with water. This helps slow down the rate at which gravel falls to the bottom of the tank. This can reduce the impact on the piping inside the tank.

2.) The second most common reason is not to cut the manifold properly. This is more common with tanks mounted on top, or tanks with valves at the top of the tank. This is important because of the weight of the valve on the pipe. If the tube is cut for too long, the tube may be crushed or overloaded, damaging the inner tube at the bottom.

3.) Other unusual practices include hot water or heat, chemical incompatibility, vacuum, pressure, manufacturing defects, corrosion, water hammer, etc.

As soon as the internal pipe of the softener system breaks, the resin leaks into the water pipe. Once the resin enters the water pipe, it is very difficult to get out and can be found years later. It is recommended to install a Y-strainer behind the softener to ensure some safety and to ensure that the resin is trapped in the strainer if the pipe breaks.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.