How does sewage undergo treatment?

The process of eliminating impurities from wastewater and residential sewage water is known as sewage treatment.

To remove contaminants, sewage treatment uses physical, biological, and sometimes chemical mechanisms. Its goal is to generate an environmentally safe sewage water, known as effluent, as well as a solid waste, known as sludge or bio-solids, that may be disposed of or reused. Sludge is frequently reused for agricultural uses, but it is also being used as a fuel source.

The introduction of contaminating elements lowers the quality of water from the mains, which is utilized in manufacturing, farming, homes (toilets, bathtubs, showers, kitchens, sinks), and hospitals, commercial and industrial locations. Pollutants such as organic wastes, suspended particulates, microorganisms, nitrates, and phosphates must be eliminated.

The concentration of toxins in wastewater must be lowered to a safe level, usually a standard set by the Environment Agency, before it may be reused or returned to the environment.

The following factors influence the characteristics of wastewater treatment systems

a) The nature of the municipal and industrial wastes that are conveyed to them by the sewers.

b) The amount of treatment required to keep the quality of the receiving streams and rivers.

Treatment plant discharges are frequently diluted in rivers, lakes, or estuaries. They can also be sterilized and used for specific forms of irrigation (such as golf courses), carried to lagoons to evaporate, or dumped into the sea through underground outfalls. To avoid damaging the waters where they are discharged, sewage water outflows from treatment plants must fulfil effluent limits specified by the Environment Agency.

How do Flocs and Activated sludge help in Sewage Treatment?

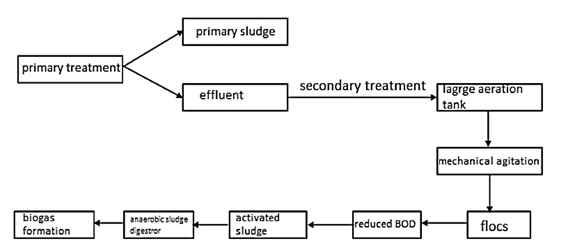

Primary, secondary, and tertiary processing are the three processes of sewage treatment.

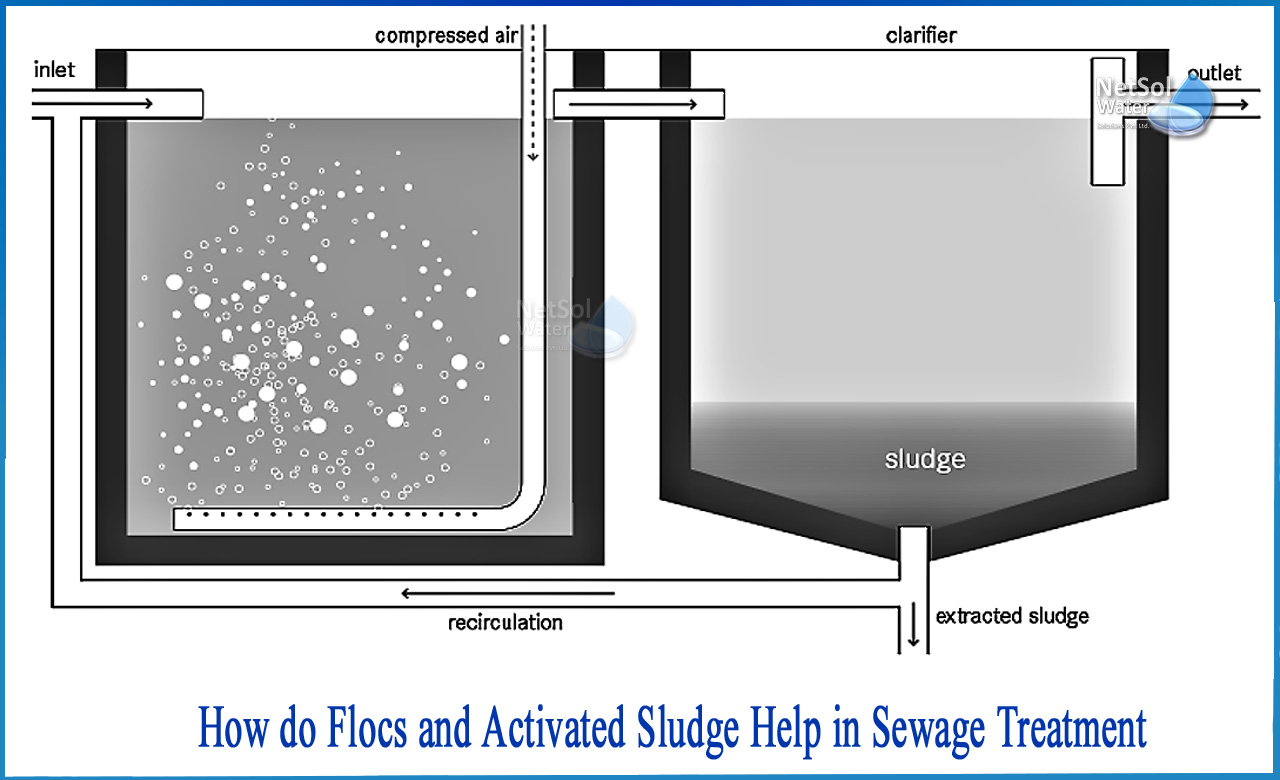

Flocs are mesh-like structures made up of masses of vital bacteria held together by slime and fungal filaments. They are in a sludge structure. They aid in accelerated aerobic decomposition by trapping particles when they are disposed of in the secondary sewage tank.Flocs are employed in the aeration tank during secondary sewage treatment to speed up decomposition. The bacteria breaks down a lot of organic materials, turning it to microbial biomass and releasing minerals in the process resulting in reduction of BOD of the sewage. As the BOD of waste is reduced to 10-15% of raw sewage, it is passed into settling tanks. The sedimentation of flocs is allowed in these tanks.

Activated sludge is sludge that has been supercharged with beneficial aerobic microorganisms by settling sewage in the presence of sufficient amount of oxygen. Activated sludge is the sediment from the settling tank. The treatment process makes use of a multi-chamber reactor unit that uses micro-organisms as a method to remove nutrients from water.

Flow chart showing role of ‘floc’ and ‘activated sludge’ in sewage treatment

A part of the effluent from the primary settling tank is mixed and is used as inoculum in aeration tanks. The remaining part is made to enter into a large tank called anaerobic sludge digester. Anaerobic bacteria, as well as aerobic microbes from activated sludge, are present in these tanks and decompose the organic matter. The residual sludge is composted or used as manure.

What can we offer?

Netsol Water have expertise in wide range of water and wastewater treatment technologies. We can customize wastewater treatment plants that will cater to all your needs and at the same time effectively treat different types of water and wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.