Wastewater Circulation

Ensuring that dissolved oxygen reaches the bottom of the activated sludge tank is the key to avoiding odours as it is the place of anaerobic digestion that causes odours. Effective circulation of wastewater can produce about the same amount of dissolved oxygen. This promotes odourless aerobic digestion.

The aeration techniques currently in use are not always effective in increasing oxygen supply and ensuring all circulation. Surface aerators circulate only to shallow depths in the water column and do not increase dissolved oxygen in deeper bodies of water. Coarse bubble diffusers do a better job of increasing dissolved oxygen, but they struggle to fight the oxygen-free zone.

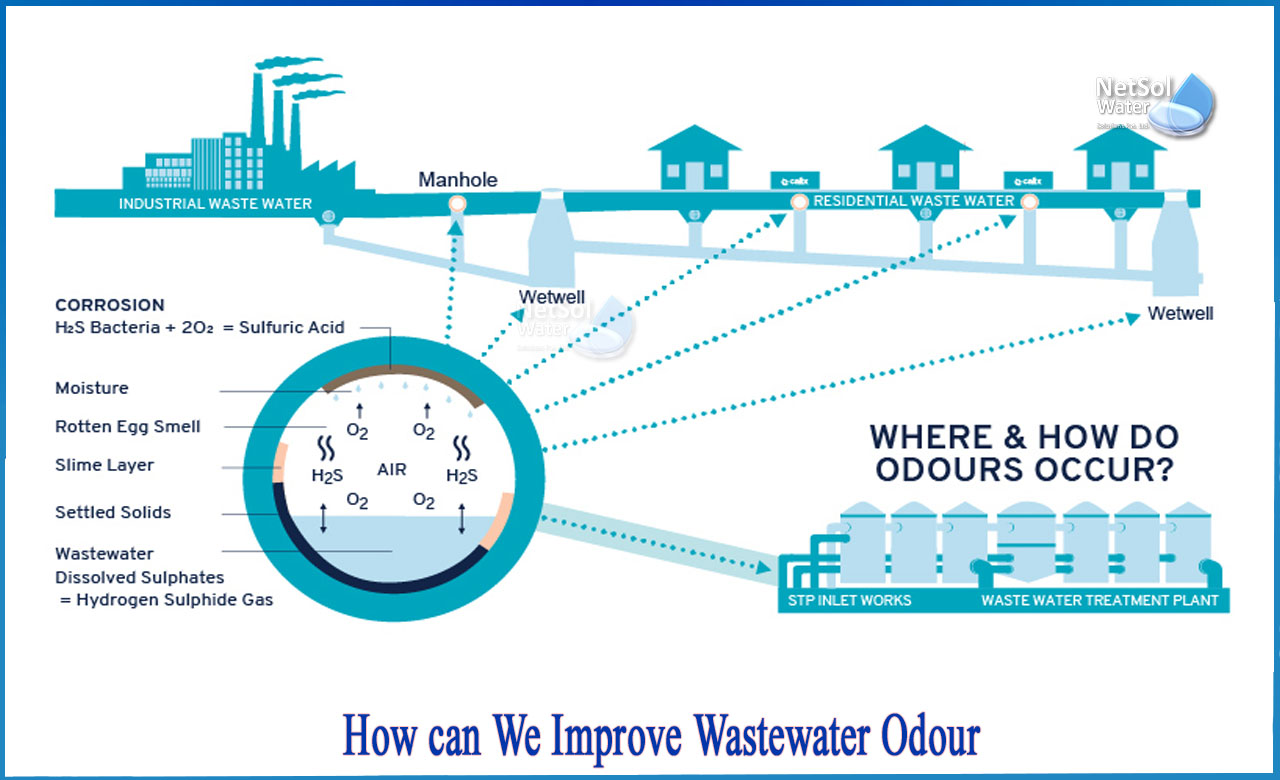

In summary, sewage treatment plants collect wastewater from local and industrial water sources for treatment. The levels of treatment applied to each plant are different, but they all have one thing in common. It is to cause an odour.

What can you do about odours?

The first step in resolving an odour problem is to identify the source. Odours can come from the inlet pumping station and raw sewage exposed to the air during the primary purification phase. Unfortunately, odours can also occur from almost every other step in the treatment train. The perpetrators can be different or a combination of these, so it is best to identify the source of the odour with the help of a professional advisor.

How can we improve wastewater odour?

There are many odour control technologies in the market, and none is universally ideal. Some plants use a deodorizing mist system to combat volatile odorous compounds in the air. Others choose to add chemicals that react with odorous compounds directly to the water. Tweaking the processing process itself is a more complex, but another odour control tactic.

What are the solutions?

Increasing Oxygen Supply

Increasing the oxygen supply ensures that aerobic bacteria have the oxygen they need to aerobically digest BOD. This slows anaerobic digestion and helps reduce odours.

The simplest approach to odour control is to literally hide the problem. Many sewages treatment plants, whether in a basin, or lagoon, shut off odour sources with industrial grade covers and thus prevent the spread of odorous vapours.

"Capture and Treat" technology is an even more powerful solution for controlling odours. The odour is captured by surrounding it with a cover and absorbing and treating the accumulated dirty air. As air moves within the duct system, it can be processed with a variety of technologies such as biofilters, wet scrubbers, carbon filters and proprietary media.

The cover not only reduces odour emissions, but also helps contain harmful greenhouse gases and minimize evaporation, thus reducing the amount of water and chemicals used in wastewater treatment.

Just as there is no "appropriate" wastewater treatment solution, there is no "appropriate" odour control cover solution. It all depends on the specific requirements of the application and the plant.

However, there are several important factors to consider when choosing a deodorant cover solution:

Airtightness: Normally, the goal is to ensure that the contaminated air is captured and that the cover is sufficiently airtight to prevent it from escaping from the leak. Less leakage means that the airtightness of the cover is also important as it allows smaller fans and duct systems to remove contaminated air, reducing both capital and operating costs. Most covers can be made airtight with a large amount of gaskets and anchors, but there is a trade-off between airtightness and accessibility.

Access and convenience: While covering the tank to control odours is beneficial, factory workers often need access to the area under the cover.

Is the inside of the tank easily accessible for sampling and routine maintenance? Does the cover have a hatch or opening to access the mixer or other equipment? Can it be installed without interrupting the operation of the plant?

Some covers require the cover to be disassembled and removed as individual parts or lifted as a unit with a crane to achieve the full accessibility required for some applications. This requires both financial and human resources and assumes that cover removal is planned as a planned maintenance activity. Full access in an emergency is difficult and even dangerous. Look for a cover that is airtight and easily accessible.

This is one such method of odour control in waste water treatment.

For more information on waste water related products, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.