What is Dissolved Oxygen and how it measure?

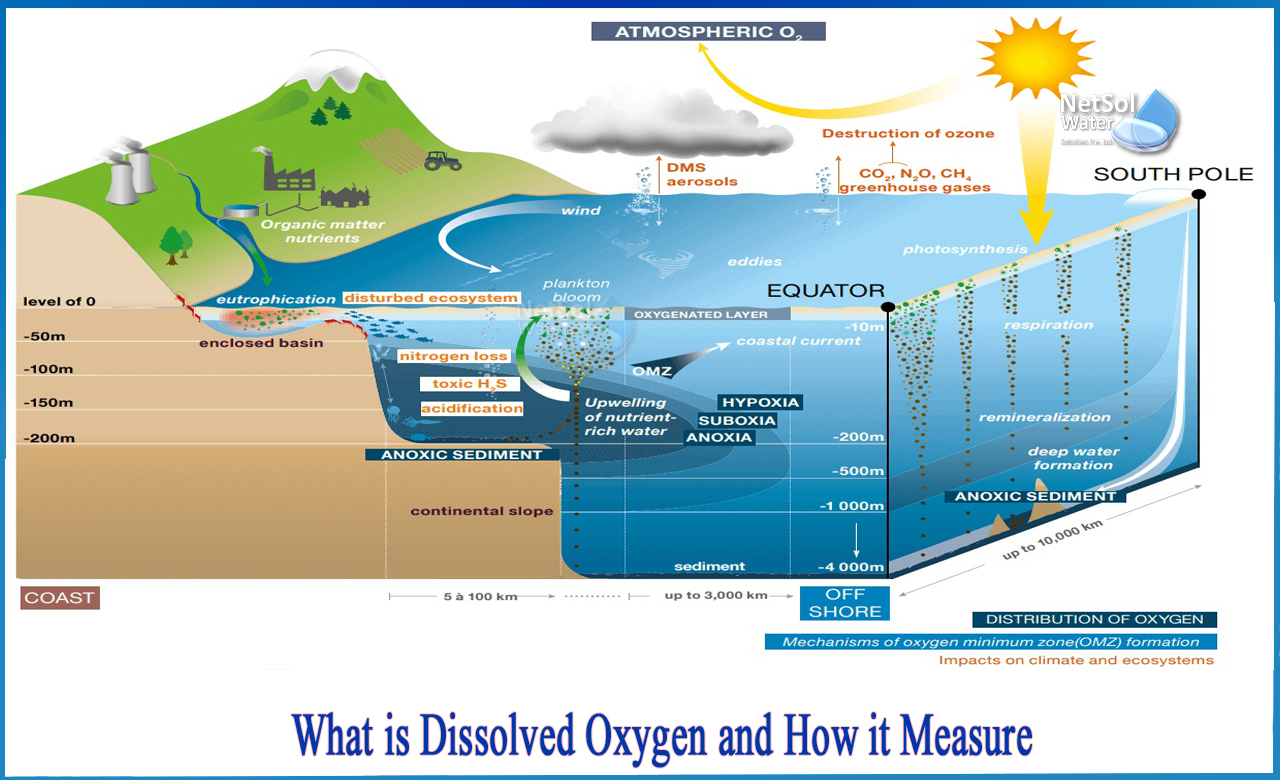

Diffusion from the atmosphere, aeration of the water as it tumbles over rocks and waterfalls, and photosynthesis all contribute to the presence of oxygen in the water. When there is an increase in nutrients and organic materials from industrial wastewater, sewage discharges, and land runoff, the oxygen content of water decreases. (Intensive land uses, such as farming, contribute more nutrients to runoff than native forest.) Excessive plant and algae growth and decay as a result of increased nutrients in waterways can have a significant impact on the amount of dissolved oxygen available.

A wastewater treatment plant differentiates solids from liquids and has two basic stages: primary treatment and secondary treatment.

Larger solids are eliminated from the wastewater during the primary treatment stage by settling.

Secondary treatment is a large biological process that eliminates the remaining suspended and dissolved solids. Secondary treatment eliminates up to 85 percent of the remaining organic material throughout a biological process that involves cultivating and adding sewage microorganisms to the wastewater. This is done in a trickling filter or an aeration tank.

Measuring dissolved oxygen levels:

Dissolved oxygen can be measured using either stationary or portable instruments. Only properly calibrated and well-maintained dissolved-oxygen metres should be used. Electronic zeros are frequently included with dissolved-oxygen metres for calibration. The accuracy of this zero-calibration feature should be tested using an absolute zero solution made of a saturated solution of sodium sulphite (procedure in the EPA-approved Analytical "Standard Methods" for Drinking Water and Wastewater).

The manufacturer's instructions, as with any piece of equipment, should be followed. Online dissolved-oxygen analysers are used in some plants to control air flow. Since these systems only measure dissolved oxygen in one location, additional dissolved-oxygen readings in biological reactors at various locations and depths should be taken on a regular basis to make sure that there are no frame rate drops. Every time a dissolved-oxygen metre is used, it must be calibrated.

A great airflow ensures not only a good dissolved-oxygen concentration, but also a modified. Reactors should be checked on a regular basis to ensure that all areas of the reactor are adequately mixed and that there are no dead spots that could lead to anaerobic conditions.

To accomplish this, take mixed-liquor grab samples at various locations and depths in the biological reactors and look for consistent suspended solids levels. The dissolved-oxygen level for aeration is determined by the type of treatment and the "risk" of low dissolved oxygen impairing aerobic microorganism output.

A dissolved oxygen of 2.0 is a good target for determining whether a system is fully mixed and aerobic, the lower the dissolved oxygen, and the more efficient oxygen transfer. Aerobic organisms, which eliminate more organic matter, are effective as long as there is some oxygen available, but there is a risk of "dead zones" at low levels. The majority of treatment organisms survive but persist in the less efficient anaerobic mode, indicating that facultative organisms can live in either condition.

Higher dissolved oxygen levels are frequently sought, but in reality, this is done to ensure proper mixing. If the dissolved oxygen level is 5.0 or higher, there is a good chance that dead zones will be minimal because normal currents and mixing will transport the oxygenated mixed liquor all across the equipment.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.