Industrial RO Plant Design Calculations Explained

The development of an industrial reverse osmosis is much more than the choice of membranes and pumps. The designing calculations made during the planning phase will be crucial in the success or failure of an RO plant. The mistakes in such computations usually have been well concealed when the equipment is commissioned, but then become apparent when the equipment fails to deliver low recovery, high energy use, constant membrane foulage or when it fails to deliver the required output.

Industrial RO plant design calculations translate raw water quality, production demand, and operating constraints into a functional and reliable system. When these calculations are made properly, the plant is consistent in its performance over the seasons as well as under conditions of different loads. Even good qualityequipments cannot make up, when it is done badly.

The Basis of Industrial RO Plant Design Calculations

All the designs of the industrial RO Plants start with the definition of the design basis. This involves quality of feed water analysis, minimum required permeate flow, target recovery, operating hours and reuse or disposal. Pressure, membrane selection and stage configuration are directly dependent on feed water TDS, hardness, silica, temperature and fouling indices.

Calculations related to the design should also take into account the changes in the quality of feed water and flow demand in the future. Average based systems are known to fail when the loads increase or when the water changes colour seasonally.

Industrial RO Plant Design Calculations

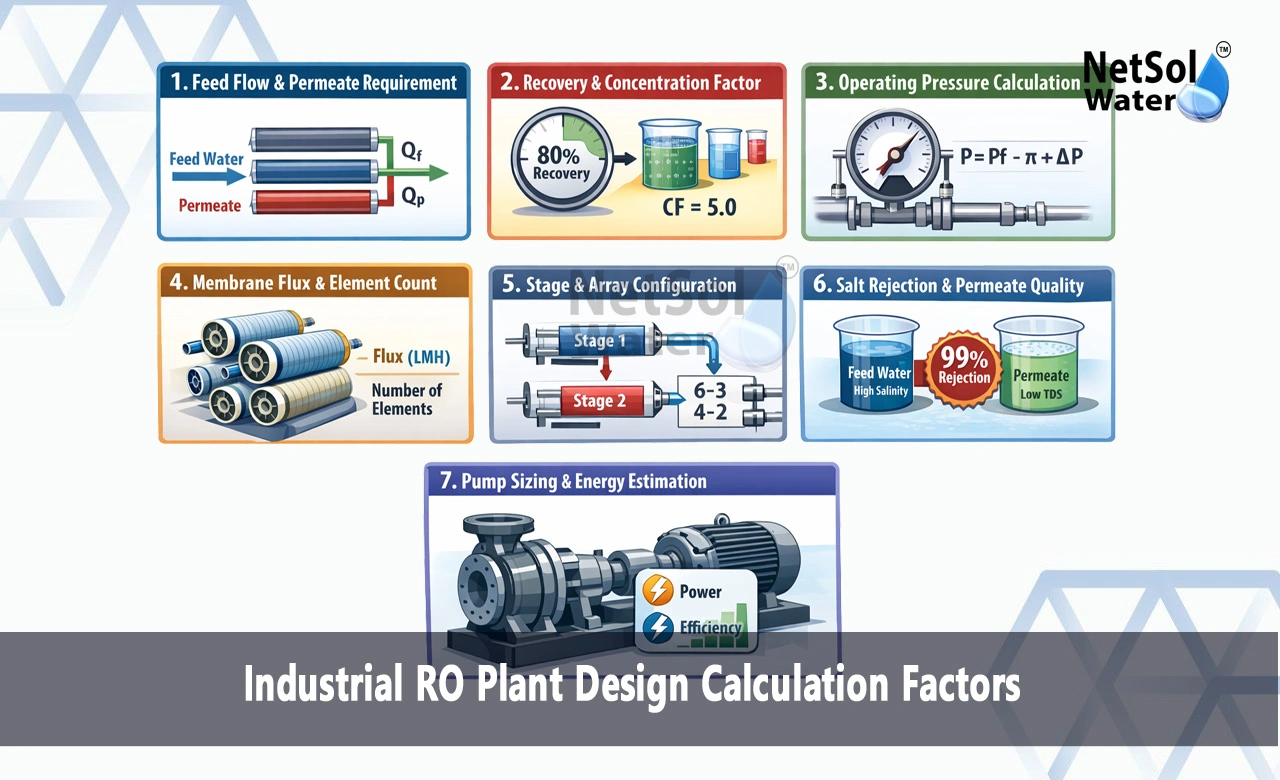

1: Flow and Requirement of Feed Water and Permeate

The initial calculation determines the amount of the treated water that needs to be generated by the plant in a day or hour. Depending on the amount of permeate flow required and the selected ratio of recovery, the total feed water flow is determined. Increased recovery will lessen the feed demand but raise the concentration pressure on membranes, which should be considered.

2: Recovery and Concentration Factor

The percentage of recovery characterizes the amount of water that is converted into permeate. The salt concentration within the system of membranes grows exponentially as recovery rises. Calculation in designing should be done in such a way that factors of concentration are not exceeding scaling limits of hardness, silica, and sulfates. This measure directly affects the life and the frequency of cleaning of the membranes.

3: Computation of Operating Pressure

The operating pressure depends on the feed water TDS, temperature correction factor, membrane resistance and desired flux. An increase in TDS and a decrease in temperature demand increase in the pressure needed to retain the flow of the permeate. This results in inaccuracy in pressure measurements thus giving rise to undersized pumps or unnecessary use of energy.

4: Membrane Flux and Element Count

Flux is a measurement of the amount of water flowing through each of the membrane elements per square unit. The calculation of design involves the required number of elements of membranes that would give the desired flow without compromising the safe flux levels. This can cause overloading of membranes with high flux, which leads to low capital cost, but this leads to early fouling and a decline in performance.

5: Stage and Array Location

Multi-stage configurations are commonly used as a way of distributing recovery and pressure in industrial RO plants. The design calculations determine the way the membranes will be laid down at each stage to regulate the flux, pressure drop and salt passage. The unsuitable design of the staging leads to uneven loading of the staging and immediate damage of the membranes in the first stage.

6: Rejection of salt and quality of the permeate

Permeate TDS is calculated based on the rates of membrane rejection and the feed water salinity. This measure will guarantee that the treated water is to process or reuse standards. Poor rejection calculation mostly results in complaints over water quality after installation.

7: Estimation of Pump Sizing and Energy

Pump capacity, motor power is determined depending on flow rate, pressure requirement and system losses. Estimates of the energy consumption at this stage assist in determininglong term operating cost and feasibility. Disregard of safety factors may lead to cavitation of pumps or a decrease in the life cycle of the system.

Typical errors in calculating RO Design in Industry

Among the most frequent errors, one should design to recover at a peak, without considering scaling chemistry. The other common problem is the application of site-specific water analysis instead of generic design assumptions. Removing the potential of fouling is also another underestimation by many plants, and aggressive flux values are chosen to reduce the number of membranes.

Failure to take into consideration the variation in temperature, future growth and actual working hours of the system will further reduce the reliability of the system. Such errors mostly lead to a high rate of shutdown, high cost of cleaning and low life of the membrane.

Conclusion

Accurate Industrial RO Plant Design calculations form the backbone of a reliable and efficient water treatment system. Although it is necessary to recover and estimate pressure, select a membrane, and size a pump, all calculations are linked. Any mistakes made during the design phase cannot be easily resolved by simply operating in the designed phase.

A properly calculated RO design provides predictable performance, controlled operating cost and long life of the membrane. Spending time and effort in making calculations of the design would result in the RO plant being able to work as anticipated not only in the commissioning, but also in the operational life.