How to design considerations of a UV System for WWTP facilities?

One of the most important factors for businesses around the world, in the fight against water scarcity is and will be water reuse. Buildings and facilities will consume less raw water from surface and groundwater sources, and spend less on delivering raw water and purifying raw water, before use if they reuse process water, grey water, and wastewater.

You might be curious about the engineering and design process, involved in UV treatment for water reuse applications.

The use of a UV treatment for water reuse applications is one of the best disinfection processes. Therefore, the main points of a UV disinfection system's design characteristics will be covered in this article, along with the reasons why a certain design might be more effective in a given application.

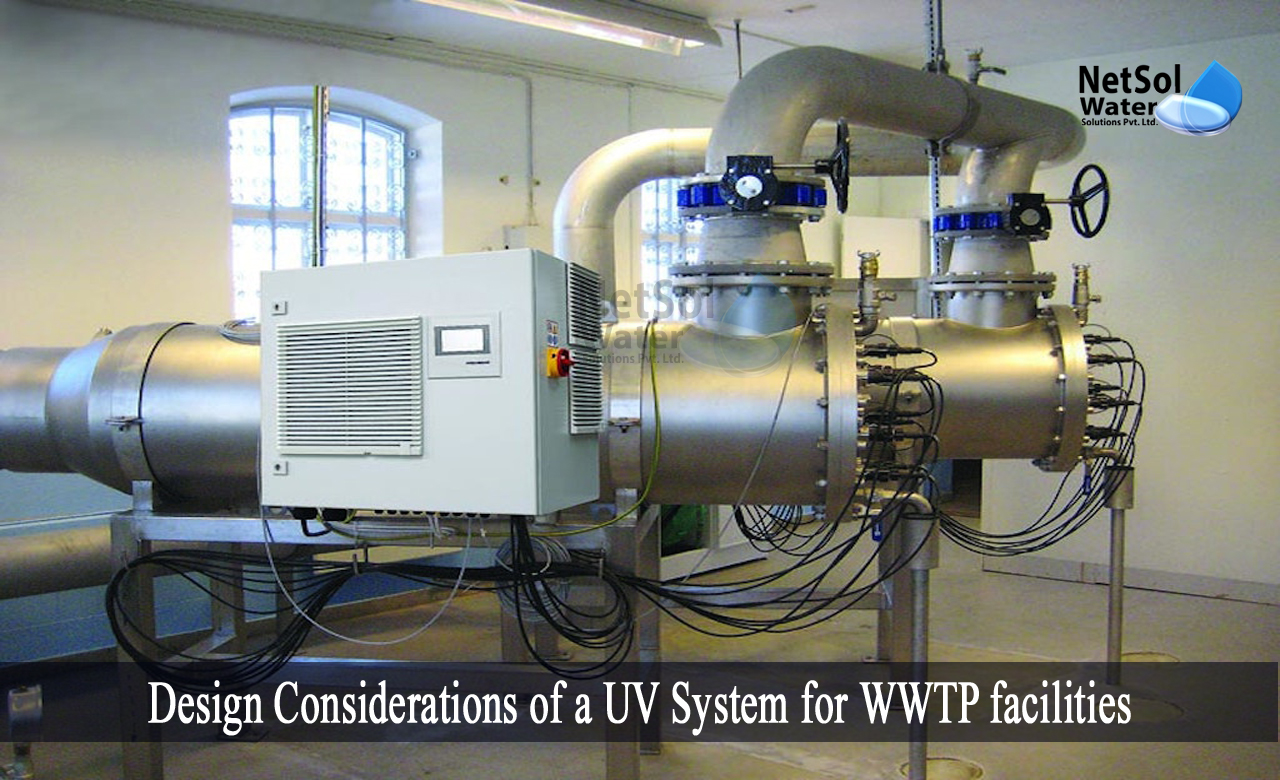

Ultraviolet (UV) system for water disinfection

In some situations, particularly those that call for water free of bacteria, reusing water can be more challenging. A tertiary treatment stage is often required for treatment at this level.

Disinfection is used to carry out this treatment, effectively killing any dangerous pathogenic organisms by rupturing their cell walls, damaging their proteins, or altering their DNA, to stop them from functioning normally and reproducing.

Due to its absence of chemical additives and convenient size, UV radiation disinfection has gained popularity over the past few decades, and is a great option for integration into current systems.

Design characteristics of a UV treatment system in water and wastewater treatment

Only a few essential parts make up UV treatment systems, which are discussed below;

- Design of the Lamp

Two characteristics of ultraviolet disinfection lamps are pressure and output. These two characteristics are formed in the lamps, at either a high or low setting. Systems for UV disinfection employ one of three types of bulbs.

1: Lamps with low pressure and low output are the most energy-efficient. These work best in applications with lower flows that want to operate with less energy. Since, they generate less light than more powerful lamps, more lamps must be used, requiring more room in the facility.

2: Low Pressure/High Output lamps are ideal for greater flow systems, seeking increased energy effectiveness. For treating the same amount of water, they have a smaller footprint than LPLO lamps, but a greater footprint than MP lamps.

3: The best and most potent bulbs are those with medium pressure. These lights have a smaller footprint than LPLO or LPHO lamps, and can manage large flow systems, if the building can support the power consumption of the lamps. In contrast to low pressure lights, they also have shorter operational lifespan.

- Reactor design

The lamps are housed in this part, which also serves as the passageway for the water that needs to be cleansed. Open and closed reactors are the two primary types.

The UV lights are lowered into the channels that have been created in open systems, which are exposed to the atmosphere. The UV lights are kept inside closed systems, which are completely enclosed. Numerous closed systems are constructed into structures that resemble pipes, and can be joined directly to a piping system inline, U-shaped, or S-shaped.

While, closed systems are more compact, they must be shut down and disassembled for maintenance, which may result in a lengthier downtime. Open systems are larger but also provide better access for maintenance.

- Lamp location

The UV lights inside the reactor can be positioned either parallel or perpendicular, to the effluent flow. Due to the nature of their construction, closed systems often place the lamps parallel to the flow, but open channels may do either.

The bed could be shallower if parallel lamps were laid horizontally in the channel, but the area of disinfection is only as large as the length of the lamps. Due to the requirement to remove the complete configuration from the channel, these systems also require more time to replace lights.

Vertically raised perpendicular lightings are placed in a much deeper channel. This expands the disinfection sections cross-sectional area, and multiple modules can be installed next to and downstream of one another, to speed up the disinfection's effective reaction time. Additionally, replacing lamps in this setup takes significantly less time than replacing the entire module, because lamps can be lifted up separately.

- Sensors for UV and UVT

It is a crucial element for determining, when maintenance is necessary, and for tracking the system's effectiveness over time. To guarantee optimum dosing, the UV sensor measures the lamp's output intensity.

UVT sensors measure transmittance, or more specifically, how well UV light penetrates the solution.A drop in transmittance may be a sign of murky water or light fouling.

How can we assist?

Do you want to find out more about UV treatment options for disinfecting process water, wastewater, or reused water? For more information, get in touch with the water treatment professionals at Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.