What causes odour at wastewater treatment plants?

The anaerobic breakdown of organic molecules at treatment plants causes bad odours. Hydrogen sulphide (H2S) is a natural by-product of anaerobic digestion that has a strong, unpleasant odour. It is discharged into the atmosphere due to its limited solubility in wastewater, resulting in a disagreeable stench.

What are the Odour control technologies?

The removal of odour from sewage treatment facilities and sewage saturated waste are two common odour control emission applications.

Complaints about odours from areas near WWTPs have been on the rise!

Several emission sources, such as pump stations, wet wells, sludge dewatering, manholes, air valve chambers, and sludge trans-shipment activities from soil to trucks, require odour control devices. The main component of sewage odour is hydrogen sulphide (H2S), which is hazardous if released into the environment.

Odour control technologies are classified into three categories:

1. Chemical absorption which includes acid and caustic wet scrubbing

2. Biological oxidation which includes bio filtration and bio-scrubbing

3. Adsorption with activated carbon and other adsorption media’s.

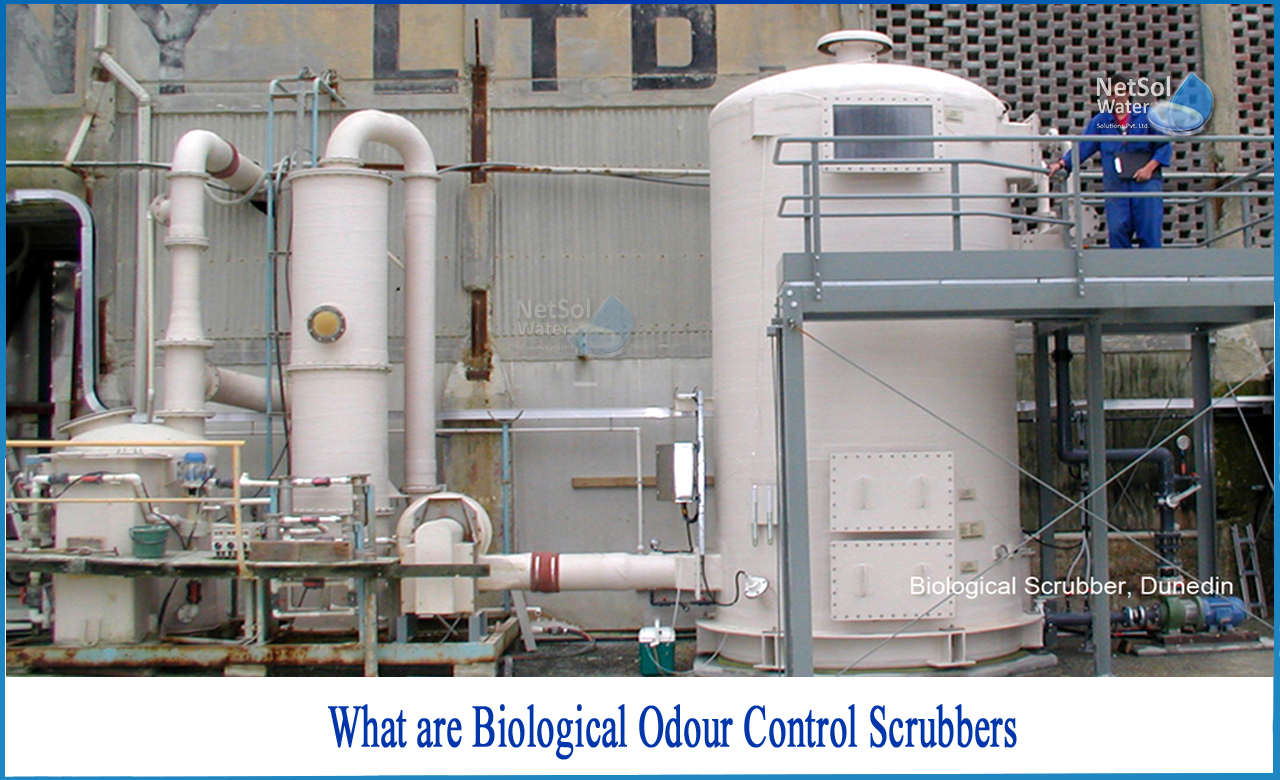

What are Biological Odour Control Scrubbers?

A Biological Scrubber is a wet odour control scrubber that processes and eliminates impurities from an air stream while only using caustic to manage the pH of the recirculation solution. There are a variety of odour control and chemical fume scrubbers, all of which play a part in the treatment of noxious or corrosive gases in the business.

In municipal applications, biological scrubbers are typically used to treat hydrogen sulphide emissions that are removed from a water or wastewater treatment process. A "degasification" or "de-carbonation" tower in a wastewater treatment system removes hydrogen sulphide gas from the water and exhausts it through an exhaust port.

Benefits of biological scrubbers

1.At >25 ppm H2S, it has lower running expenses and a better life cycle cost than chemical scrubbers and carbon filters.

2. It has a small footprint.

3. H2S is removed at a rate of >98%, which is superior to soil bed filters. Even at greater H2S concentrations - up to 200ppm –it has proven performance.

4. It is easy to operate. There are no chemicals required; only modest amounts of nutrients are required.

5. Performance that is consistent. There is no decrease in performance over time or as a result of the weather.

6. All critical processes are contained within vessels, making it extremely controlled.

7. There are no hidden running expenses.

8. Upgrading an existing system to cut operational costs, it's possible to add to an existing arrangement.

9. Extensible, having the ability to improve the quality of air discharge in the future by installing a carbon bed.

How does biological odour scrubbers work?

The biological scrubber is based on an initial seeding of small microorganisms (bacteria) that connect to the internal media substrate or packing, offering both a location to attach as well as a place to breed and multiply while in direct contact with contaminated air. The bacteria are used to break down and digest pollutants, and they feed on them as a food source, allowing them to not only survive but also to grow and proliferate.

When using a Biological Odour Scrubber to treat and remove hydrogen sulphide (H2S), the by-product created is a waste in the form of Sulphuric Acid, which is produced as the Sulphur. The sulphuric acid waste lowers the pH of the recirculating water, perhaps making it unfit for bacteria to grow and thrive. As a result, the Biological Scrubber requires the addition of caustic or another kind of base to buffer the water and maintain a healthy pH environment in order to protect the bacteria colony and equipment.

The captured gas carrying impurities is often pushed into the bottom of a vertical Biological Tower Scrubber using a "Forced Draft" approach, similar to how gas enters any other form of chemical scrubber or single or multiple pass odour control scrubber. The gas stream then ascends and passes over a cultured media bed with live microorganism growing on its surface.

What can we do to assist?

To provide you with the right system for your business, get in touch with Netsol Water. We are one of the leading water treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing.

To learn more about our water and wastewater treatment products, contact us at +91 9650608473 or contact via email at enquiry@netsolwater.com