What is a Membrane Bioreactor (MBR)?

A membrane bioreactor (MBR) is a wastewater treatment system that combines a membrane process such as reverse osmosis, microfiltration or ultrafiltration with a biological wastewater treatment system such as activated sludge. It is now widely employed in the treatment of municipal and industrial wastewater.

MBRs creating effluents of higher quality!

MBR methods can create effluent of high quality that can be discharged to coastal, surface, or brackish rivers or recovered for urban irrigation when utilized with household wastewater. Small footprint, easy retrofit, and modernizing ageing wastewater treatment plants are some of the other advantages of MBRs over conventional procedures.

When compared to conventional settling separation systems, MBR procedures may function at greater mixed liquor suspended solids (MLSS) concentrations, allowing the reactor volume to be reduced while maintaining the same loading rate.

There are two MBR configurations:

1: Internal/submerged, where the membranes are immersed in the biological reactor and are an intrinsic part of it;

2: External/side-stream, where membranes are a separate unit process that requires a pumping phase in the middle.

Why are Membrane Bioreactor Systems (MBR) important? Why is there a need for MBRs?

The need for MBR technology is driven by rising Environmental concerns about industrial wastewater disposal, as well as depleting freshwater resources in developing economies. The corporate picture will be bolstered by population expansion, urbanisation, and industrialization. Depending on their composition, these changes may place a strain on natural resources and provide unsustainable environmental concerns.

As a result, membrane bioreactor (MBR) technology is viewed as a critical component of modern wastewater treatment and reuse schemes, and it is geared at achieving sustainable water management in both municipal and industrial settings.

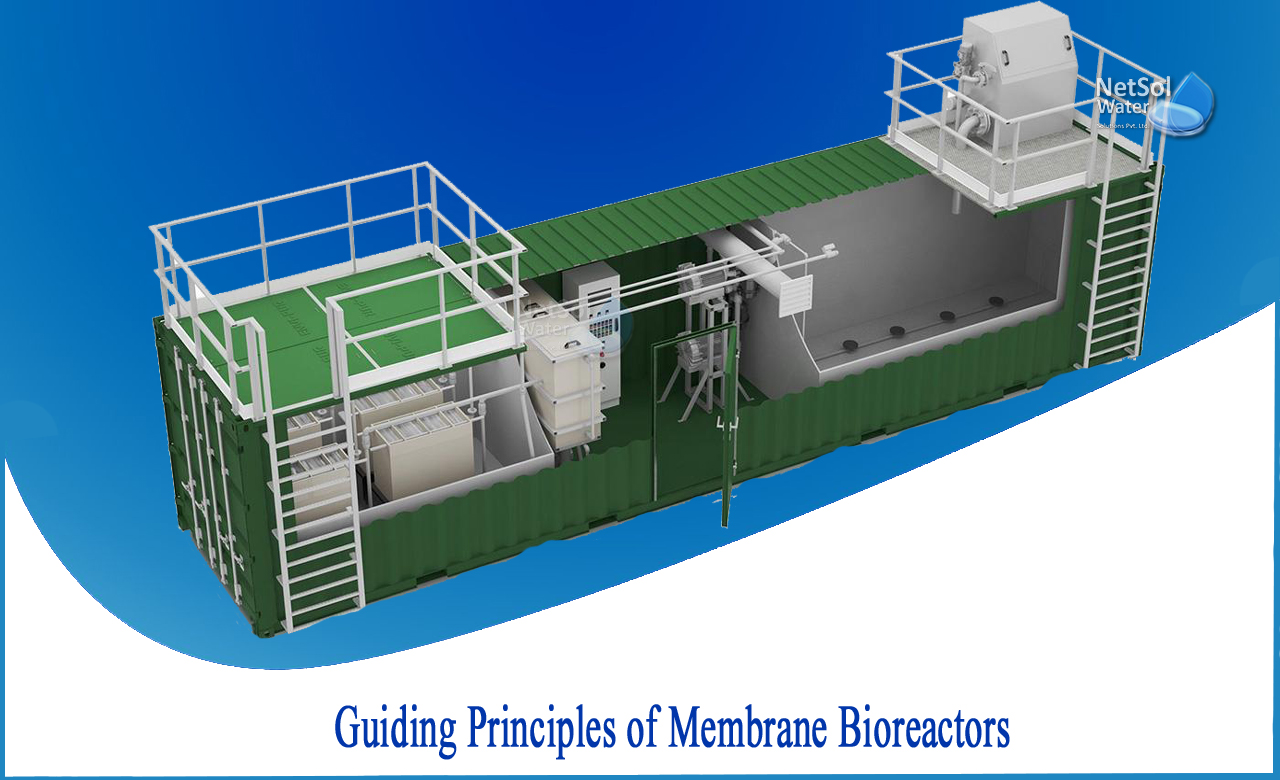

What are the Guiding Principles of MBR Systems?

The essential principles of membrane bioreactor (MBR) technology, including biological treatment, membrane filtration, and MBR applications, are applied in municipal and industrial wastewater treatment and has grown in commercial importance during the last decade.

Design Principles of Membrane Bioreactors (MBRs)

The follow?ing factors play a significant role in the design of a membrane bioreactor system:

1: Membrane configuration refers to the geometry of the membrane (hollow fibre, flat sheet, or tubular) as well as the direction in which the water flows through it (in-to-out or out-to-in);

2: The membrane separation process configuration refers to the location of the membrane module in the overall MBR process, which can be either within or outside the tank;

3: The biochemistry is determined by the bio treatment process set-up, in order to know

-what contaminants are eliminated (organic carbonaceous materials, ammonical compounds and nutrients),

-what items are created (carbon dioxide or methane, nitrate or nitrogen, etc).

Operation and Maintenance in Membrane Bioreactors (MBR)

Most MBRs need chemical maintenance cleaning once or twice a week for 30–60 minutes, and recovery cleaning once or twice a year when filtration is no longer effective.

If you want to know more about Netsol’s range of Membrane Bioreactors, thenyoucan have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.