Gasification and Plasma Vitrification of Sewage Sludge from Treatment Plants

Managing sewage sludge from municipal wastewater treatment facilities poses a major environmental test. This semi-solid residue left over after treating domestic and industrial wastewater contains contaminants like heavy metals, pathogens, and organic pollutants. Improper sludge disposal risks soil, groundwater and air pollution. Conventional methods like landfilling and incineration have drawbacks - potential for leachate formation, greenhouse gases, and toxic air emissions. As a result, there's growing interest in advanced thermal technologies offering more eco-friendly, sustainable sewage sludge solutions - gasification and plasma vitrification.

Understanding Gasification

Gasification converts organic sewage sludge into combustible syngas in a specialized gasifier reactor. It involves drying the sludge, then pyrolysis (decomposing organic matter without oxygen to produce char, tar, gases). With controlled oxygen, the char/tars react to generate syngas - mainly carbon monoxide, hydrogen, methane plus carbon dioxide, nitrogen.

The syngas produced during gasification can be utilized for various applications, such as electricity generation, heat production, or as a feedstock for the synthesis of chemicals and fuels. Gasification offers several advantages over conventional sewage sludge management methods, including reduced volume of residues, as a large portion of the sewage sludge is converted into syngas, and the potential for energy recovery through the combustion of the produced syngas. Additionally, gasification takes place in a controlled environment, which helps to minimize air pollutant emissions compared to incineration.

Understanding Plasma Vitrification

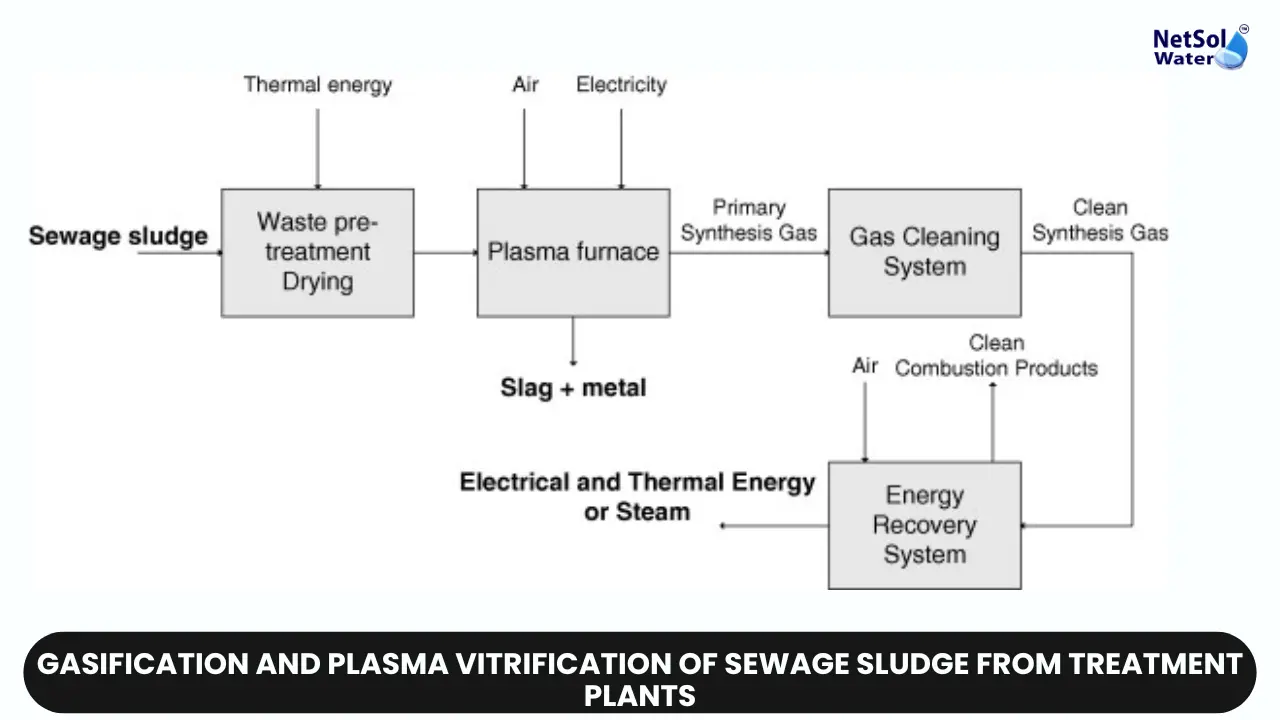

Plasma vitrification uses extreme plasma arc furnace heat (up to 16,000°C) to convert sewage sludge into chemically inert, vitrified slag. The dried sludge enters the furnace where intense plasma heat decomposes organics while inorganic components like heavy metals melt and vitrify into non-leachable glassy slag.

This process significantly reduces sludge volume (up to 90%), completely destroys organics while immobilizing heavy metals/inorganics in the stable vitrified slag. It operates in a closed system minimizing emissions, and produces inert residue safe for disposal or reuse.

Plasma vitrification offers several advantages for sewage sludge management:

Volume reduction: The process significantly reduces the volume of the sewage sludge, typically by up to 90%.

Immobilization of contaminants: The high temperatures ensure the complete destruction of organic pollutants, while heavy metals and other inorganic contaminants are effectively immobilized within the vitrified slag.

Reduced emissions: The plasma arc furnace operates in a closed system, minimizing the release of air pollutants.

Inert residue: The vitrified slag produced is chemically inert and non-leachable, making it suitable for safe disposal or potential reuse as a construction material.

Conclusion

Both gasification and plasma vitrification represent promising advanced thermal treatment technologies for the management of sewage sludge from wastewater treatment plants. These processes offer significant advantages over conventional methods, such as reduced emissions, volume reduction, and the potential for energy recovery or the production of inert residues.

The choice between gasification and plasma vitrification will depend on factors such as the composition of the sewage sludge, energy requirements, and the desired end-products. Gasification is particularly suitable when energy recovery is a priority, as it produces a combustible syngas that can be used for power generation or as a fuel source. Plasma vitrification, on the other hand, is more appropriate when the primary goal is the immobilization and stabilization of contaminants, as it produces a chemically inert, non-leachable vitrified slag.

As environmental regulations become more stringent and the demand for sustainable waste management practices increases, advanced thermal treatment technologies like gasification and plasma vitrification are likely to play an increasingly important role in the management of sewage sludge from wastewater treatment plants.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com