What is the Importance of STP Plants in Hospitals?

In today's world, wastewater treatment has become a need in a variety of fields!

When it comes to hospitals, they consume a lot of water every day and generate a lot of effluent. Sewage from medical facilities or hospitals contains hazardous contaminants that must be treated before being discharged into the sewer.

What is Hospital Sewage and why is it vital to cure it?

We should first learn about wastewater.

It is either water that has been contaminated by numerous activities or water that contains dangerous compounds. Sewage from hospitals comes from a variety of places, including the ICU, emergency room, canteen, laboratory, and many other places. Hospital sewage contains a number of hazardous components that are harmful to both the environment and humans. As a result, therapy is required.

STPs for Hospitals are used to address wastewater issues in medical settings. Its goal is to properly treat wastewater before releasing it into the environment, as the wastewater created by the hospital has a negative impact on humans and environment.

According to the Pollution Control Board, hospitals are required to install a STP for adequate wastewater treatment.

Characteristics of Hospital Sewage

1: Microbial pathogens, dangerous bacteria, and viruses are found in wastewater from various hospitals.

2: Pharmaceuticals and their by-products.

3: Isotopes of radioactivity.

4: Toxic compounds and heavy metals.

5: Drug metabolites

In hospitals, the wastewater treatment process is as follows-

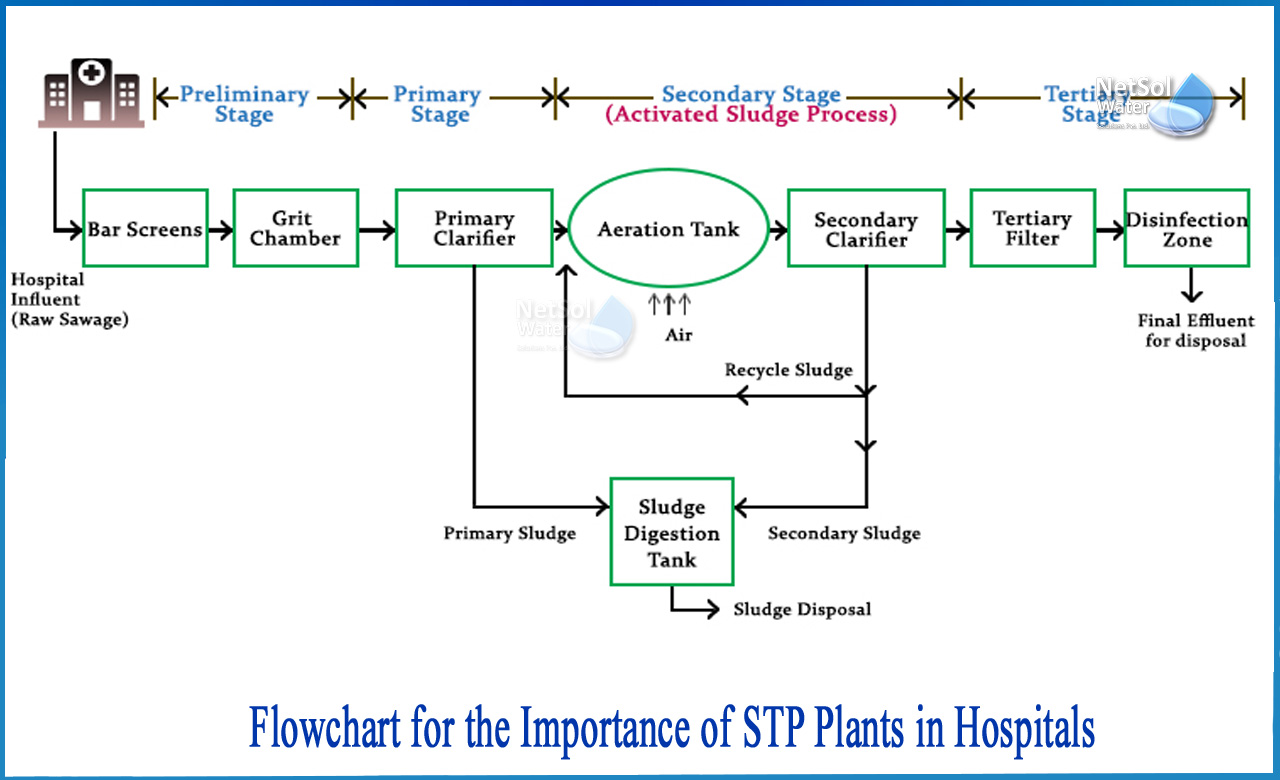

A sequence of processes are followed to construct a compact or packaged sewage treatment system for hospitals.

The following is a list of traditional treatment procedures for removing pollutants or contaminants:

1: The Preliminary Stage, also known as Pretreatment: In most sewage treatment plants, the preliminary treatment procedure is required as a first step. Through bar screens, it eliminates huge trash such as sticks, rags, and other large debris, as well as heavy inorganic particles, from the hospital influent. The removal of these debris preserves the plant's equipment. Grit is the inorganic sediment that is removed using a grit chamber.

2: The second step in the sewage treatment system is the primary treatment stage. This stage involves the physical separation of particles and greases from wastewater. Water is now pumped through primary filters or clarifiers for a few hours to allow solid particles to settle and lighter particles to float to the top of the tank, where they will be skimmed off. Primary sludge, also known as primary effluent, is a settled material that comprises 60-70 percent solids. The wastewater that has been partially treated is now submitted to the next degree of treatment.

3: Secondary Treatment Stage: This biological treatment stage eliminates dissolved inorganic elements from wastewater that are soluble and colloidal. Bacteria are employed to transform colloidal and dissolved organic materials in this process. The partially treated wastewater from the primary tank now flows into the aeration tank, where oxygen for bacteria is provided by an air blower. When wastewater runs into a secondary clarifier, solids settle out, forming secondary sludge. Part of this is recycled for the activated sludge process, while the rest is combined with primary sludge and sent to a sludge digestion tank before being disposed of. Inorganic solids are removed at this step to the tune of 90%.

4: In most STPs, the tertiary or advanced treatment stage is the last stage. The suspended particles and organic debris that were not removed during secondary treatment are removed in this stage. The disinfection procedure will eradicate harmful bacteria that were not removed during the biological treatment process. Depending on the state of the wastewater, a variety of disinfection agents might be utilized (pH, clarity etc.). Reverse Osmosis, Chlorine, UV radiation, ozone, and other physical or chemical disinfectants are used to achieve this.

Disinfected wastewater may now be disposed of or reused.

Technical assistance and guidance

Netsol Water is a well-known company that creates these plants for the best sewage treatment outcomes.

These plants are built out of MBBR technology, which is highly popular. The primary goal of this architecture is to remove solid and liquid waste from wastewater, allowing water to be reused.

Our plants come in a variety of types and sizes, such as 100 KLD, 200 KLD, 500 KLD, 1 MLD, and much more. This system's unique method benefits a large number of individuals throughout the world. These plants are beneficial not just in hospitals, but also in hotels, malls, complexes, and canteens, among other places. These frameworks are also created in accordance with these locations.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.