Sewage Treatment Plant (STP) is an essential part of any commercial building, including malls and multiplexes, to ensure the safe and efficient disposal of wastewater. The design of an STP for a mall or multiplex depends on several factors, including the expected water usage, the type and quantity of pollutants present in the wastewater, and the local regulatory requirements.

In this blog, we will discuss the design basis, process flow diagram, and working function of an STP for malls and multiplexes.

Design Basis

The design basis for an STP for malls and multiplexes typically includes the following factors:

- Water Usage: The water usage in malls and multiplexes can vary widely depending on the size of the building, the number of visitors, and the facilities available. The STP design must take into account the expected water usage to ensure that the treatment capacity is sufficient to handle the volume of wastewater generated.

- Type of Pollutants: The wastewater generated in malls and multiplexes may contain a variety of pollutants, including organic matter, suspended solids, oils and greases, and other contaminants. The STP design must be tailored to handle the specific type and quantity of pollutants present in the wastewater.

- Regulatory Requirements: Local regulatory requirements for wastewater treatment must be taken into account when designing an STP for a mall or multiplex. The design must meet the effluent standards for discharge into the environment or be suitable for reuse within the building.

Process Flow Diagram

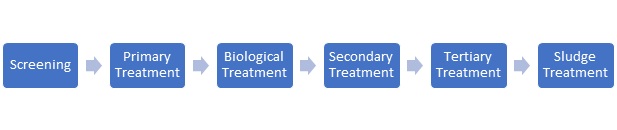

The process flow diagram for an STP for malls and multiplexes typically includes the following steps:

1. Screening: The wastewater is screened to remove large solids and debris that could damage downstream equipment.

2. Primary Treatment: The wastewater is settled in a primary clarifier, where solids settle to the bottom and are removed as sludge.

3. Biological Treatment: The wastewater is treated in an aerobic bioreactor, where microorganisms break down organic matter into carbon dioxide and water.

4. Secondary Treatment: The wastewater is settled in a secondary clarifier, where the remaining solids are removed as sludge.

5. Tertiary Treatment: The wastewater is treated with tertiary processes such as filtration, disinfection, and de-chlorination to meet the effluent standards or reuse requirements.

6. Sludge Treatment: The sludge removed from the primary and secondary clarifiers is treated separately to remove moisture and stabilize the solids before disposal or reuse.

Working Function:

The STP works on the principle of removing pollutants from the wastewater through physical, chemical, and biological processes. The screening process removes large solids and debris that could damage downstream equipment. The primary clarifier settles the wastewater to remove solids and oils, while the aerobic bioreactor breaks down organic matter using microorganisms. The secondary clarifier removes remaining solids, and the tertiary treatment processes, including filtration, disinfection, and de-chlorination, further treat the wastewater to meet effluent standards or reuse requirements. The sludge treatment process separates and stabilizes the solids removed from the primary and secondary clarifiers for disposal or reuse.

Conclusion

Designing an STP for malls and multiplexes requires careful consideration of the expected water usage, type and quantity of pollutants present in the wastewater, and local regulatory requirements. The process flow diagram and working function of the STP are essential for understanding the different steps involved in the treatment process and the role of each component in ensuring the safe and efficient disposal of wastewater. The STP is an essential component of any commercial building to ensure the protection of the environment and the health and safety of the building occupants.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com