What is flow pattern in reactor in Wastewater Treatment Plants?

Treatment of wastewater is necessary to speed up the natural process of water purification. This will also facilitate protection of environment, because the wastewater collected from cities and towns contains elements toxic to human health and the ecosystem. Wastewater must be treated to facilitate its return to water bodies or to groundwater. The role of design engineer is to develop a process that will guarantee the technical feasibility of the treatment process, taking into consideration other factors such as construction cost, maintenance cost, availability of construction materials and equipment’s, as well as specialized labour.

Primary treatment only, will not produce an effluent with an acceptable organic material concentration!

Biological processes are used in the treatment systems to effect secondary treatment for removal of organic material. In biological treatment systems, the organic material is assimilated by bacteria. Depending upon the requirement for the final wastewater quality, tertiary treatment methods and/or pathogen removal may also be included.

Today vast number of wastewater treatment plants use aerobic treatment for the removal of organic matter. Most used aerobic processes are the activated sludge process, oxidation ditch, trickling filter, and aerated lagoons. Stabilization ponds makes use of both the aerobic and anaerobic mechanisms. In the recent years due to increase in power cost and subsequent increase in operation cost of aerobic process, attention is being paid for the use of anaerobic treatment systems for the treatment of wastewater including sewage. Recently at few places, the high rate anaerobic process such as Upflow Anaerobic Sludge Blanket (UASB) reactor followed by oxidation pond is used for wastewater treatment.

Characterization of Wastewater

The characteristics of the wastewater differs from city to city and industry to industry for domestic wastewater, depending upon the standard of living of the people and commercial and industrial activities in the city.

For Indian cities, the per capita SS can be considered as 90 to 95 gm per day and BOD as 40 to 45 gm/day. The BOD linked with suspended solids is usually at a rate of 0.25 kg of BOD per kg of SS.

The wastewater treatment facility can be designed for 100% removal of pollutants, but the treatment will become uneconomical. Also certain amount of pollution load can easily by assimilated by watercourses without having serious impacts on the environment.

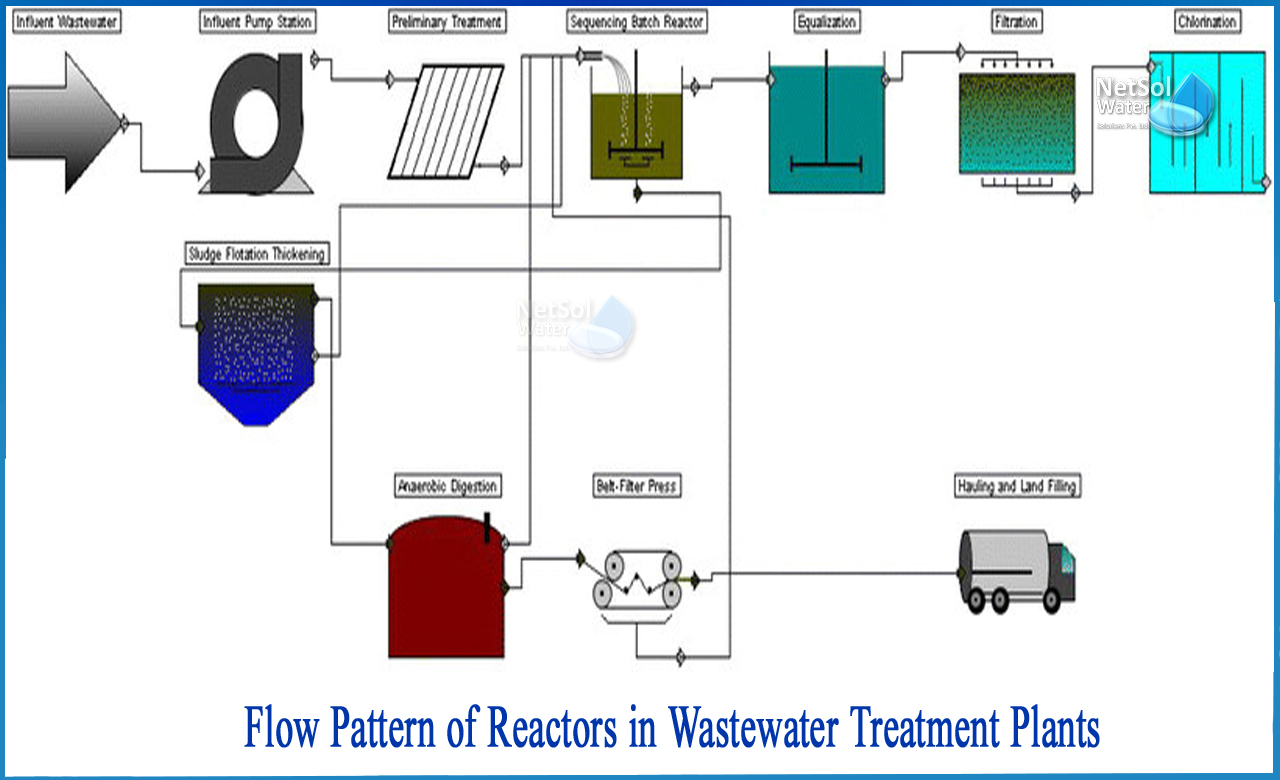

Flow Patterns of Reactors

The flow pattern in the reactors is dependent on mixing conditions in them.

Some of the factors on which the mixing conditions depend are:

The shape of the reactor, the size and scale of the unit, up-flow velocity of the water, rate of biogas generation or the rate of gas supplied, etc.

Flow pattern affect the exposure time for each treatment and substrate distribution in the reactor. Depending upon the flow pattern the reactors are classified as:

(a) Batch reactors: In this type of reactor, the wastewater flow is not continuous and these reactors are operated as fill and draw type. The mode of operation of these reactors is batch mode with fill time, reaction time, and withdrawal time.

(b) Ideal plug flow reactors: In this type of reactor, the fluid particles flows through the tank and are discharged in the same sequence in which they enter in the tank. The particles remains in the tank for a time same to theoretical detention time.

(c) Ideal completely-mixed flow reactors: In this reactor type, particles are dispersed throughout the tank as they enter the tank. The content in the reactor are completely mixed thus are homogeneous at all points in the reactor.

(d) Arbitrary flow reactors: Partial mixing between plug flow and completely mixing condition exists in this reactor. Each element of the incoming flow remains in the reactor for different duration of time. It is also called as dispersed flow reactor.

(e) Packed bed reactors: Packing medium, such as, rock, slag, ceramic or synthetic plastic media are filled in these reactors. They can be anaerobic filter, when no air is supplied, or aerobic (trickling filter) when flow is intermittent or submerged aerobic filter when compressed air is supplied from the bottom.

The hydraulic regime in the reactor is defined with respect to the ‘Dispersion number’, which gives the characterization of mixing condition in the reactor as:

Dispersion Number = D/UL

Where,

D = Longitudinal or axial dispersion coefficient, L2/t

U = Mean flow velocity in the reactor, L/t

L = Length of longitudinal travel path, L

For ideal plug flow,

D/UL = 0, since by definition, dispersion is zero.

D/UL £ 0.2 for regime approaching plug flow conditions.

D/UL ³ 3.0 to 4.0 for regime approaching completely mixed conditions.

Conclusion

Netsol water is one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines like compact sewage treatment plants which not only turns your waste water into usable water but also acts as a savior of Mother earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.