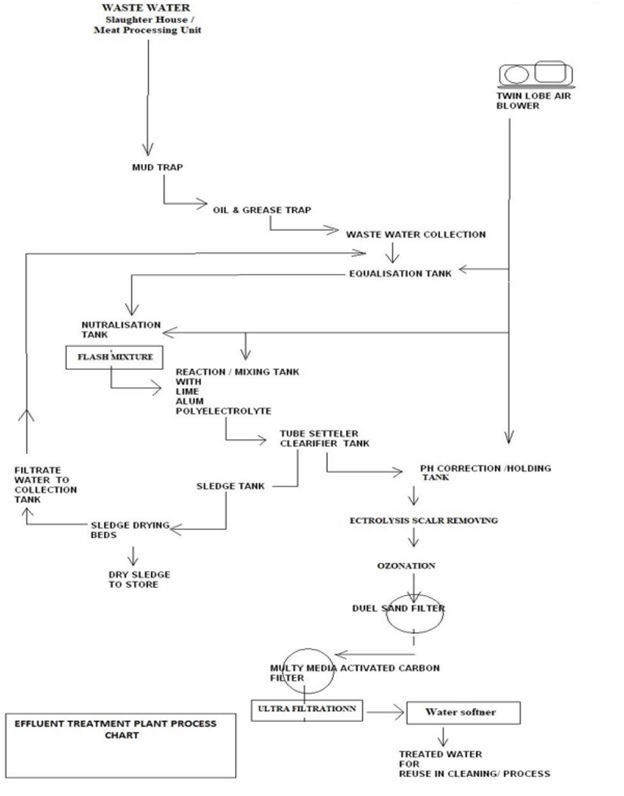

Flow chart of Effluent Treatment Plant for Slaughterhouses

We are already aware that a slaughterhouse is a facility, where animals are slaughtered, for human consumption. Slaughterhouses supply meat, which is subsequently packaged by a packaging company.

Effluent produced by Slaughterhouses

Meat processing effluents are regarded as harmful, due to their complex mix of lipids, proteins, fibers, high organic content, microbes, and veterinary drugs. Due to the large range of pollutant loading, slaughterhouse effluents are frequently evaluated using bulk characteristics. Slaughterhouse wastewater (SWW) has a high BOD, a high COD, a high total organic carbon (TOC), high total nitrogen (TN), high total phosphorus (TP), and a high total suspended solids content (TSS), content.

Effluent sources from the Slaughterhouse

![]() Lairage

Lairage

![]() Slaughter and Bleeding

Slaughter and Bleeding

![]() Dressing

Dressing

![]() Paunch Handling

Paunch Handling

![]() Rendering

Rendering

Processing & Cleaning

Properties of slaughterhouse wastewater

Because of the SWW complex composition of lipids, proteins, fibers, high organic content, microorganisms, and medications for veterinary reasons, meat processing effluents are deemed toxic globally.

This table summarizes the typical qualities of a genuine SWW:

|

Parameter |

Range |

Mean |

|---|---|---|

|

BOD (mg/L) |

150–8500 |

3000 |

|

COD (mg/L) |

500–16,000 |

5000 |

|

TOC (mg/L) |

50–1750 |

850 |

|

TN (mg/L) |

50–850 |

450 |

|

TP (mg/L) |

25–200 |

50 |

|

TSS (mg/L) |

0.1–10,000 |

3000 |

|

K (mg/L) |

0.01–100 |

50 |

|

Colour (mg/L Pt. scale) |

175–400 |

300 |

|

Turbidity |

200–300 |

275 |

|

pH |

4.9–8.1 |

6.5 |

As a result of the SWW's different properties, it is suitable to categorize and reduce wastewater output at its source. Because of the large quantity of water consumed during slaughtering, processing, and cleaning of slaughtering facilities, meat processing effluents are becoming one of the primary agribusiness issues.

Flow chart of Effluent Treatment Plant for Slaughterhouses

Stages of Effluent treatment in Slaughterhouses

1. Pretreatment

To remove bigger solid particles from wastewater, pre-treatment generally employs physical techniques, such as filtering and settling, as an effluent flows into the treatment tanks and basins, during pretreatment. Larger materials, such as tree branches, leaves, and plastic waste, are filtered out by massive bar screens.

Equalization tanks (EQ tanks) control water flow to facilitate settling, while grit chambers allow minute particles such as dirt, sand, gravel, coffee grinds, and eggshells to settle.

2. Primary Treatment

Its primary objective is to remove particles from effluent using gravity, and on-going physical processes.

Pre-treated water gathers in primary clarifiers during basic effluent treatment. The effluent is allowed to settle for a while, so that any remaining contaminants can precipitate out.

3. Secondary Treatment

It employs bacterial rather than physical methods. It employs helpful microorganisms, to break down more of the wastewater's solid contaminants.

4. Tertiary Treatment

The tertiary treatment adds further filtration and disinfection. In contrast to primary and secondary treatment, it is typically optional in most effluent treatment plants. ETPs frequently employ it, when they must fulfil, especially severe effluent regulations.

Advantages of utilizing Netsol's Slaughterhouse effluent treatment plant

The follow?ing are the main advantages of Netsol WaterSolutions Slaughterhouse Effluent Treatment systems:

· It complies with all of the environmental organization's criteria and rules.

· It produces odourless and colourless recycled water.

· These are completely automated.

· The components are long-lasting and non-corrosive.

· These do not produce any noise pollution.

· Sludge creation is kept to a minimum.

· It has high efficiency in removing BOD, COD, and contaminants.

Conclusion

In high quantities, slaughterhouse effluent contains a diverse spectrum of organic compounds (e.g., proteins, blood, fat, and lard). The treatment of slaughterhouse effluent is crucial, for preventing contamination of the environment. The most often used methods for treating slaughterhouse wastewaters include fine screening, sedimentation, coagulation-flocculation, trickling filters, and activated sludge processes. Disinfected wastewater is sent back into the environment after the final treatment.