What is Sewage Treatment?

Sewage treatment is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding waterbody or on to the land. It involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with advanced processes and nutrient removal.

Goal of Secondary Treatment Processes

The goal of secondary wastewater treatment is to significantly reduce the biological component of sewage. This might be accomplished using chemical unit operations or biological processes that use bacteria as a catalyst for pollution removal.

Biological treatment processes are commonly used for removal of organic matter from the wastewater. Because of its efficacy and simplicity, the Extended Aeration (EA) system is one of the most often used biological systems to treat household wastewater.

The bacteria may digest the organic waste and survive and reproduce in the treatment plant because it supplies the correct environment, adequate oxygen, and other components. The aerobic bacteria and micro-organisms breakdown the sewage and garbage in this way, leaving it in a stable, odourless state.

What is STP based on extended aeration systems?

Extended aeration process is one of the modifications of Activated Sludge Process (ASP).

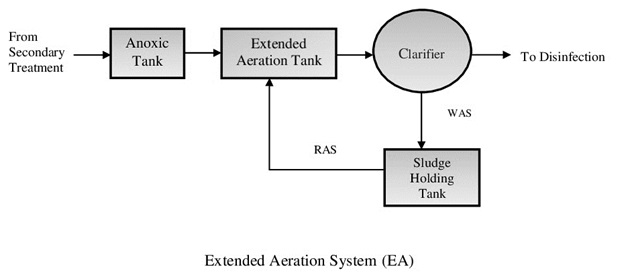

This system includes aeration and mixing, settling, sludge return and removal of solids. It is a complete mix process providing biological treatment to wastewater for the removal of biodegradable organic wastes under aerobic conditions. Mechanical or diffused aeration are used to provide the oxygen required to sustain the aerobic biological process. Mixing is done to maintain the contact of microbial organisms with the dissolved organics. Since there is complete stabilization in the aeration tank, there is no need for separate sludge digester.

Primary sedimentation tank is also discarded and settleable organic solids are also allowed to settle in the aeration tank due to long detention time in the aeration tank. It employs low organic loading rate (F/M), long aeration time and high MLSS concentration. Due to long detention in aeration tankthe cells undergo endogenous respiration. The excess sludge generated in this process is low and does not require separate digestion and the sludge can directly be applied on the sand drying beds where aerobic digestion and dewatering of the sludge occurs.

Operational steps of Sewage treatment plant based on extended aeration systems

1. The raw residential wastewater from the final manhole is pumped into the primary screen, which has a mechanical coarse screen to filter coarse solids.

2. A set of raw sewage pumps will next lift the screened sewage up to the secondary screen within the wet well.

3. To eliminate finer solid debris in the sewage, a heavy-duty mechanical fine screen is placed in the secondary screen chamber.

4. Following the fine screen chamber, two aerated grit chambers are proposed for eliminating inert materials such as fine sand and gravel.

5. Last but not least, a grease/oil removal system is employed in the pre-treatment system to remove any possible oil in the sewage and guarantee that the extended aeration system performs well.

Benefits of Extended Aeration Systems

a) Mechanical task that is simple to maintain.

b) Because there is a longer detention period for nutrients to be digested by microorganisms, extended aeration techniques are frequently better at handling organic loading and flow changes.

c) Systems are odourless, may be put in a variety of settings, have a tiny footprint, and can be planted to blend in with the surroundings.

d) Because of the lengthy sludge ages, extended aeration systems have a low sludge yield, may be engineered to offer nitrification, and do not require a primary clarifier.

How can Netsol Water help?

We are one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines which not only turn your wastewater into usable water but also acts as a savior of Mother Earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.