Water scarcity, according to the United Nations, is one of the world's biggest challenges today and tomorrow. It is critical to create long-term solutions for new freshwater sources; systems that take a direct route from saline to fresh water at a low cost and with minimal environmental damage.

Sea Water Reverse Osmosis (SWRO) is one of the most sustainable and cost-effective options for converting sea water to potable fresh water due to its great energy efficiency and reliability. Simultaneously, SWRO technology is rapidly evolving in order to enhance energy efficiency and support large-scale freshwater production.

People in many parts of India have come to accept Seawater Reverse Osmosis (SWRO) desalinated water as an alternative method to drought relief. However, a few people still believe the following of myths and fallacies. To dispel myths and misconceptions, clarifications are supplied.

Myth #1: Water Desalinated from Municipal Desalination Plants do not have enough minerals and use of desalinated water can result in depletion of minerals from the body!

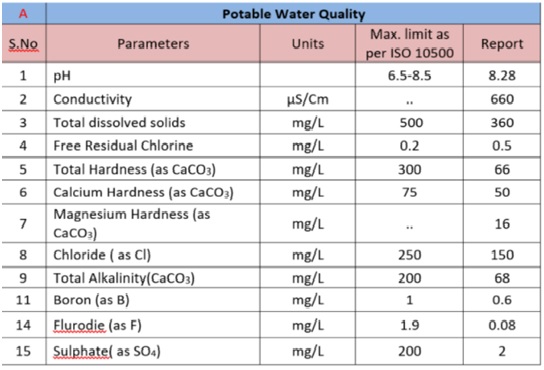

The SWRO plant's design is adaptable, having a modular and multistage setup that can generate water to any standard. The resulting potable water is of excellent quality, consistent, and free of bacteria and viruses. SWRO plants can create potable water that meets the ISO 10500 standard or the World Health Organization (WHO) regulation, or they can be built to produce high purity water. Total Dissolved Solids (TDS) is 10 mg/l process water for industries.

Typical analysis of selected potable water parameters from a desalination plant are given below:

Myth #2: Desalination plants in that area destroy fish and other marine life!

The conservation of marine life is prioritised in the construction of desalination plants. The intake is constructed with a large flow area so that water enters the velocity head at a very low velocity, preventing fish, fish eggs, and other marine life from being brought in. Deep within the sea, the intake velocity head is located. As a result, marine life is protected from being dragged along with seawater. Only salt water is discharged from the desalination plant, with no impurities or chemicals. Before being dumped into the water, the chemical cleaning solutions are neutralised. Sludge is removed from backwash waters by many plants before it is dumped into the sea.

Myth #3: Desalination plants raise the salinity of groundwater near the coast!

The recovery rate (the percentage of low salinity water recovered from seawater) is 40 to 45 percent. The salt rejected from the RO plant's separation of 45 percent low salinity water is returned to the sea as brine, together with 55 percent saltwater. However, after a distance of 50 metres from the discharge point, the brine becomes diluted and approaches the salinity of saltwater. As a result, the salinity of seawater near the beach remains unchanged.

Myth #4: The cost of desalinated water is prohibitively expensive!

Due to advancements in membranes with higher productivity, innovation in energy recovery devices, economy of large capacity units, more efficient higher capacity pumps, and other factors, the cost of desalinated water has decreased significantly in the previous 30 years. New desalination technology will very certainly lower the cost of desalinated water even more.

Myth #5: Desalination uses a lot of energy!

SWRO used about 8.5 to 9 kWh/m3 of water produced in the 1980s. Plant recovery was in the 30 to 35 percent range, and plant capacity was significantly lower. Today, because to advancements in energy recovery devices, high flux RO membranes, and large capacity facilities with more efficient pumps, energy usage has dropped to 3 to 3.5 kWh/m3. New desalination technologies such as Forward Osmosis and Membrane Distillation Process, as well as advanced membrane technologies, are being researched to reduce specific power consumption even more.