Electrochemical Treatment for Advanced Wastewater Purification

Electrochemical Treatment for Advanced Wastewater Purification offers a clear path to cleaner water and safer reuse. This method uses electric current and special electrodes to change or remove pollutants. It works well for hard to treat chemicals and for micro pollutants that other systems miss. Plant operators can add electrochemical units to existing lines or use them in new plants. The process can break down complex molecules, remove colour and cut down on pathogens. It also helps reduce the mass of sludge that needs disposal. Engineers can control the process with simple signals and sensors. Investors can compare cost and benefit in a straight forward way. The technology shows promise across small plants and large utilities.

Principles and Mechanisms

Electrochemical Oxidation

Electrochemical oxidation uses anode surfaces to create reactive species that break pollutant bonds. The process turns complex organics into simpler molecules that are easier to remove. Operators set current intensity and contact time to match pollutant load. The method works well when direct chemical oxidation and indirect oxidation act together.

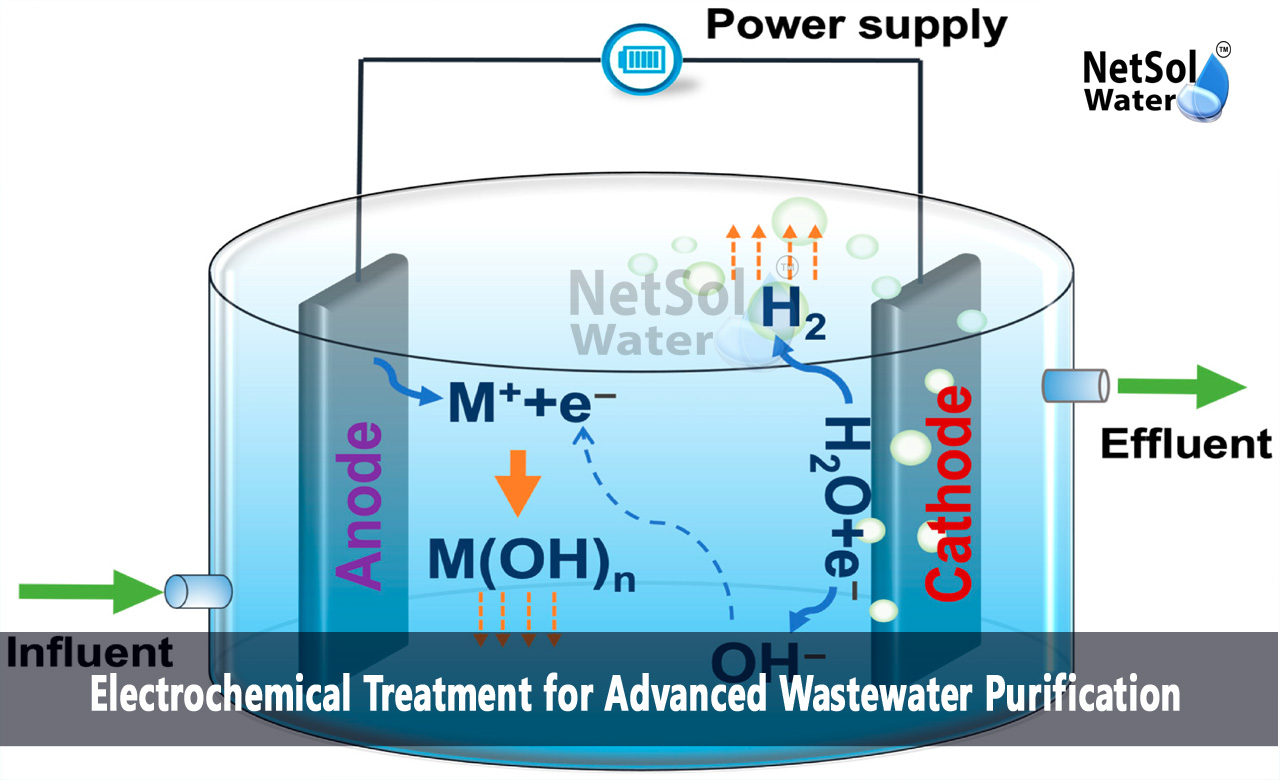

Electrocoagulation and Electroflotation

Electrocoagulation forms metal hydroxides that capture suspended solids and some dissolved compounds. Electroflotation brings these clumps to the surface for easy removal. Plants can tune the process to remove metals and some microplastics. These steps reduce the load on later filters and membranes.

Electrode Reactions and Byproducts

Electrodes drive reactions that either mineralize pollutants or move them into a removable phase. Designers must check for unwanted byproducts such as chlorinated compounds in chloride rich waters. Careful control of potential and contact time limits byproduct formation and keeps treated water safe.

Read: Sewage Treatment Plant Manufacturers

Electrode Materials and Design

Carbon-Based Electrodes

Carbon electrodes offer wide potential windows and low cost. They resist corrosion and work well with organic pollutants. Operators find them easy to replace and to scale in modular units.

Metal and Mixed Oxide Electrodes

Metal based electrodes such as mixed oxides improve reaction rates for specific targets. They show strong performance for oxidation and for disinfection. These electrodes demand careful selection to balance cost and lifetime.

Reactor Layout and Flow Design

Electrode spacing flow path and contact time shape removal efficiency. Reactor trays and packed designs change how water meets electrode surfaces. Designers plan for easy cleaning and for varying flow volumes to keep performance steady.

Treatment Targets and Performance

Pharmaceuticals and Personal Care Products

Electrochemical systems break down many trace pharmaceuticals that pass through conventional plants. The systems reduce biological activity and lower the risk of endocrine disruption in receiving waters. Operators can measure load and tune the unit to meet target removal.

Industrial Dyes and Persistent Organics

Electrochemical oxidation removes colour and reduces toxicity for many dye molecules. The method shortens the life of stubborn organics and makes their residues easier to handle. Plants can combine oxidation with adsorption to reach strict discharge limits.

Pathogen Control and Disinfection

Electric driven processes can inactivate bacteria and viruses without adding chemicals. This feature helps plants meet public health goals while cutting on chemical storage and handling. Operators set voltage and contact time to reach disinfection targets.

Energy Use and Operational Considerations

Power Demand and Optimization

Electrochemical units consume electricity in direct relation to current and time. Smart control systems adjust power based on real time load and water quality. Pulse modes and intermittent operation can cut energy use while keeping performance strong.

Maintenance and Electrode Life

Electrodes wear through use and need replacement or regeneration. Regular cleaning and monitoring extend life and cut total cost. Plants plan spare parts and routine checks to avoid downtime.

Integration with Renewable Energy

Solar panels and other renewable sources can supply part of the power need. Direct links to renewables reduce operating cost and lower the carbon footprint of the treatment plant. This option suits sites with variable power pricing.

Integration and Scaling

Pilot Testing and Phased Adoption

Pilot units help teams prove performance and set design values for full scale units. Pilots run at real flows and help set electrode area and power needs. This step reduces risk and speeds up adoption.

Hybrid Systems and Polishing Steps

Electrochemical units work best when they join biological treatment membranes and filters. The system can polish effluent to meet reuse standards. Hybrid layouts let plants use strengths of each method while balancing cost.

Regulatory Acceptance and Permits

Operators must show regulators that new units meet discharge rules and that byproducts remain safe. Clear trials and reporting help secure permits and build public trust.

Conclusion

Electrochemical Treatment for Advanced Wastewater Purification offers a flexible path to remove hard to treat pollutants and to cut pathogen risk. Proper design and clear tests let plants match performance to local goals. Plant teams can run pilots choose the best electrode and link the unit into existing lines. If you want more information or a practical review of your site contact our team for a consultation. We will visit your plant, examine needs and propose steps that fit your budget and schedule.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com