How to Design period and discharge of sanitary sewage system?

Before starting the actual laying work, it is necessary to plan the sewerage.

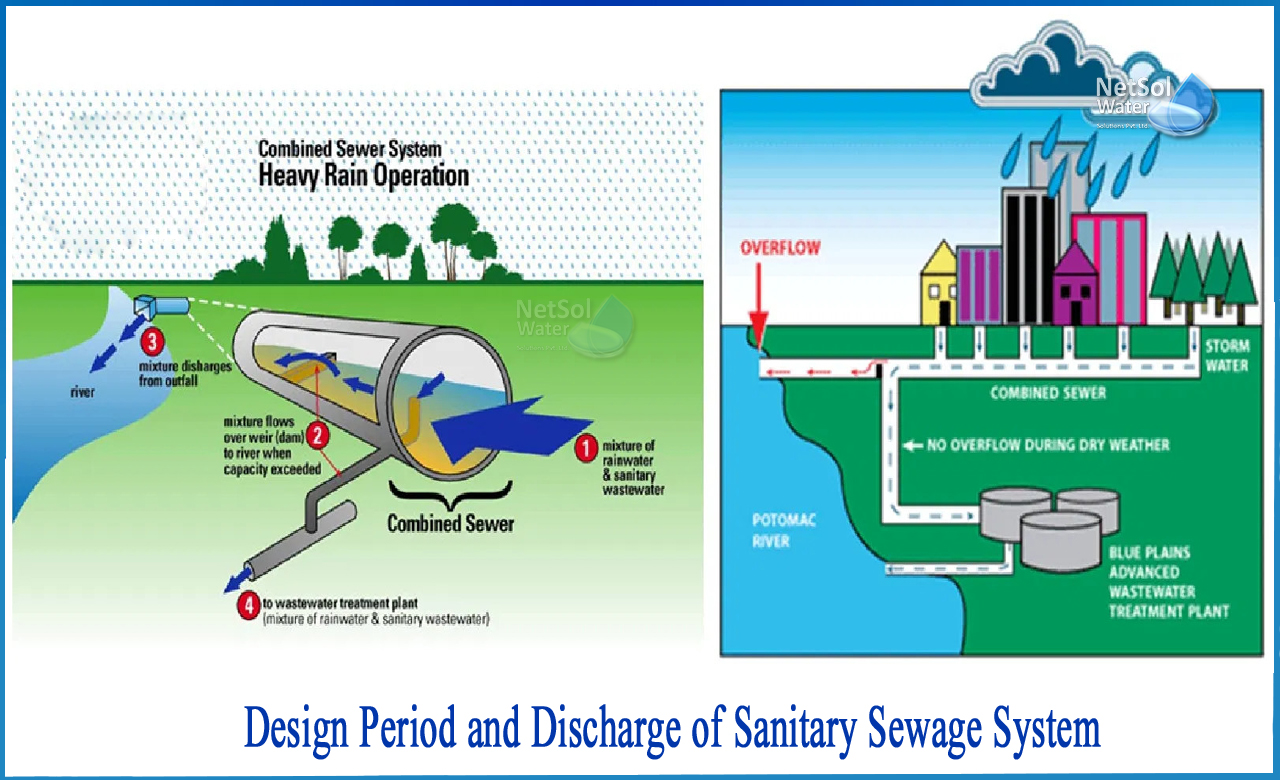

The design includes estimating the period in which the sewer will correspond to the expected population, and the emissions for which the sewer will be designed.

Design period (T)

The period until the capacity of channels becomes sufficient is called the design period.

When determining the design period, it is necessary to consider the service life of the structures and equipment’s to be used, taking into account aging and wear. Since runoff is highly dependent on the population supplied, population density, and water usage, lateral and sub-main sewers are typically designed for peak population and flows at saturation density, as specified. The general approach to sewer design is same as for water mains. They are usually designed for 25 -100 years in general.

You can consider the following planning periods for the various components of the sewer system.

1. Sides less than 15 cm in diameter: full development

2. Trunk or major sewerage: 40-50 years

3. Treatment session: 15 to 20 years

4. Pumping station: 5 to 10 years

However, the two main differences between the basic principles of sewer design and the basic principles of water pipe design are:

1: Presence of Particles

The water transported by the water pipe is virtually free of organic and inorganic solid particles. On the other hand, sewers have such particles floating in them, which can settle to the bottom of the sewer and eventually lead to sewer blockage. Therefore, sewers need to be laid on slopes and must be able to withstand the wear caused by the wear of these particles.

2: Pressure

The water main pipes normally carry water under pressure and hence, within certain limits, they may be carried up and down the hill.

The sewers, on the other hand, are open channels, therefore, they must be laid at continuous gradient in downward direction.

If sewage has to be carried under pressure, it will require elaborate equipment installation at each house which is to be connected to the drainage system.

Minimum and Maximum velocities

The deposition of particles of solid matter is not desirable in sewers and hence, the sewer should be laid at a gradient at a minimum velocity, which will prevent the silting of particles in sewers, developed over a wide change in discharge of sewage.

This minimum velocity is known as self-cleansing velocity and for keeping the sewers free from any trouble; this velocity should be developed at least once in a day.The speed of self-cleaning depends on the type of solids in the sewer and the size of the sewer.

Conclusion

There are many aspects of design life of a sewerage system and each must be fully understood and must be considered in designing the system.

If you need any information about types of wastewater and sewage treatment plants best suited for you, get in touch with Netsol water. An expert from our technical sales team can provide any additional information you require.

Netsol water is one of the leading water and wastewater treatment company in India with services in the field of WTP plant manufacturing, WWTP plant manufacturing, STP plant manufacturing and much more.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.