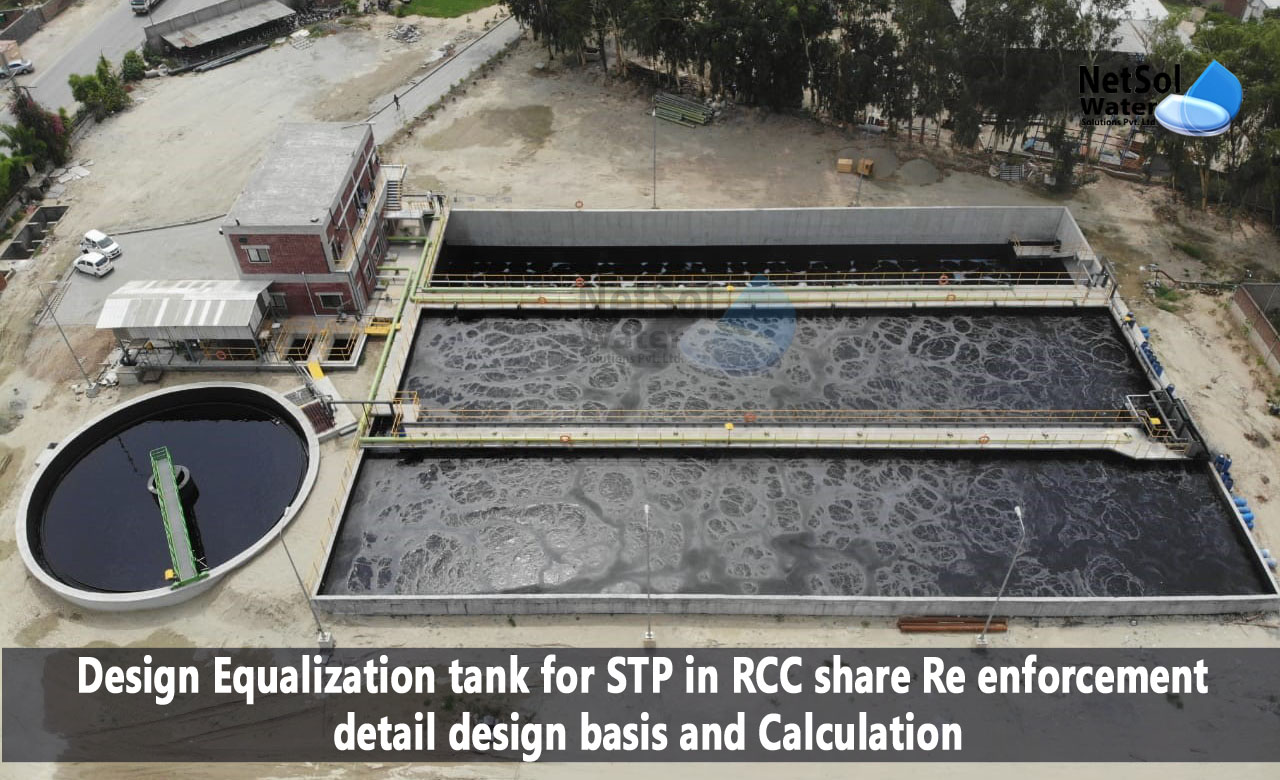

Equalization tank for STP in RCC: Design, Re-enforcement & Calculation

Sewage treatment plants are designed to treat wastewater before it is discharged into the environment. The Equalization tank is an essential component of a sewage treatment plant. The primary function of the Equalization tank is to hold wastewater when the inflow rate exceeds the treatment capacity of the plant. The wastewater is then gradually released from the Equalization tank to the treatment plant at a rate that the plant can handle.

Design Basis:

The design of an Equalization tank for a sewage treatment plant depends on the inflow rate and the peak flow rate. The inflow rate is the rate at which wastewater enters the Equalization tank, while the peak flow rate is the maximum rate at which wastewater enters the Equalization tank. The Equalization tank must be designed to hold the wastewater for a specific period, typically 24 hours, to ensure that the treatment plant can handle the flow rate.

Calculation:

The calculation for designing an Equalization tank involves several steps. First, the inflow rate and peak flow rate must be determined. The peak flow rate is usually estimated based on the population served by the sewage treatment plant. The inflow rate is determined by measuring the flow rate of wastewater entering the plant over a specific period.

Once the inflow rate and peak flow rate have been determined, the volume of the Equalization tank can be calculated. The volume of the tank is calculated using the following formula:

V = Q x T

Where V is the volume of the tank in cubic meters, Q is the peak flow rate in cubic meters per day, and T is the detention time in days.

The detention time is typically 24 hours, which means that the Equalization tank should hold enough wastewater to supply the treatment plant for a full day.

Reinforcement Detail and Design:

- Vertical reinforcement: The vertical reinforcement in an Equalization tank consists of a series of vertical bars that are placed at regular intervals along the walls of the tank. The spacing of the bars and the diameter of the bars depend on the height and width of the tank.

- Horizontal reinforcement: The horizontal reinforcement in an Equalization tank consists of a series of bars that are placed in a grid pattern throughout the tank. The spacing of the bars and the diameter of the bars depend on the size of the tank and the load that the tank is expected to bear.

- Mesh reinforcement: Mesh reinforcement is also used in some Equalization tanks. The mesh consists of a series of interconnected bars that are arranged in a grid pattern. The mesh provides additional strength and support to the concrete walls of the tank.

- Cover reinforcement: The cover reinforcement is the reinforcement that is placed near the top of the tank, where the concrete is most susceptible to cracking. The cover reinforcement consists of a series of bars that are placed in a grid pattern near the top of the tank.

- Tie reinforcement: Tie reinforcement is used to connect the vertical and horizontal reinforcement in the tank. The tie reinforcement consists of a series of bars that are placed at regular intervals along the walls of the tank.

The design of the reinforcement detail for an RCC Equalization tank is specific to the tank's size, shape, and expected load. A structural engineer should be consulted to determine the appropriate reinforcement detail for the tank. The engineer considers various factors such as the soil type, water table level, and other environmental conditions to ensure that the tank is structurally sound and meets all safety standards.

Conclusion:

Designing an Equalization tank for a sewage treatment plant requires careful consideration of various factors such as inflow rate, peak flow rate, and detention time. The volume of the tank can be calculated using the inflow rate, peak flow rate, and detention time. The tank is usually constructed using RCC, and the reinforcement detail is designed by a structural engineer. An appropriately designed Equalization tank is essential for ensuring that the sewage treatment plant can handle the flow rate of wastewater and operate efficiently.

If you are curious to know more about the treatment processes, feel free to contact us an at +91-9650608473 or enquiry@netsolwater.com