Design a Sewage Treatment Plant in Hilly Areas

Sewage treatment is a crucial process to prevent the contamination of natural water bodies from human waste. In hilly or hill areas, designing a sewage treatment plant (STP) poses a unique challenge due to the difficult terrain, limited space, and variable wastewater flow rates.

Here we have tried to provide a step-by-step design process to design a sewage treatment plant that can perform better in hilly areas, including a process flow diagram and working function.

What is the catch?

Designing a sewage treatment plant for hilly areas is a complex task that requires careful consideration of various factors such as topography, climate, land availability, cost, and environmental impact.

There is no single design that can suit all situations, but some general principles can be followed.

Things to keep in mind while designing STP on Hills:

These are some points to keep in mind while designing STP on hilly areas:

1. High elevation and steep slopes make it difficult to lay pipelines and maintain gravity flow.

2. Low population density and dispersed settlements make it uneconomical to construct centralized treatment plants.

3. Limited land availability and high land cost restrict the size and location of treatment plants.

4. High rainfall and runoff increases the hydraulic load and dilute the sewage.

5. Low temperature and solar radiation affect the performance of biological treatment processes.

6. High environmental sensitivity and aesthetic value require high standards of effluent quality

Design and Working Process:

The design of a sewage treatment plant involves selecting an appropriate combination of various unit operations and unit processes to achieve a desired degree of contaminant removal. The selection of unit operations and unit processes depends on the characteristics of raw sewage, degree of purification required, disposal facilities available, cost involved, ease of construction and maintenance, benefits that accrue from better environmental sanitation, location, availability of land and topographical conditions.

· Collection System Design:

The first step in designing an STP is to collect wastewater from the community. In hilly areas, gravity-fed systems are ideal because they require less energy and are less prone to blockages than pumped systems. The collection system should also be designed to accommodate peak flow rates during heavy rainfall events.

· Preliminary Treatment:

The collected wastewater must undergo preliminary treatment to remove large solids, debris, and grit that may cause blockages in the treatment process. This can be achieved through a combination of screens, grit chambers, and sedimentation tanks.

· Primary Treatment:

After preliminary treatment, the wastewater is directed to primary treatment tanks where settling takes place. The heavier solids settle at the bottom, forming sludge, while the lighter solids float to the surface, forming scum. The settled sludge is pumped out for further treatment, while the scum is skimmed off.

· Secondary Treatment:

The primary-treated wastewater is then directed to secondary treatment tanks, where it undergoes biological treatment. This process involves the use of aerobic bacteria to break down the organic matter in the wastewater.

In hilly areas, trickling filters are a common type of secondary treatment, as they require less space and can handle variable flow rates.

· Tertiary Treatment:

After secondary treatment, the wastewater undergoes tertiary treatment, which removes any remaining contaminants, including nutrients and pathogens. This can be achieved through a combination of processes such as sand filtration, disinfection, and chemical treatment.

· Sludge Treatment:

The sludge generated in the primary and secondary treatment stages requires further treatment before disposal. In hilly areas, the most common method of sludge treatment is anaerobic digestion, which involves the use of bacteria to break down the organic matter in the sludge, producing biogas as a by-product.

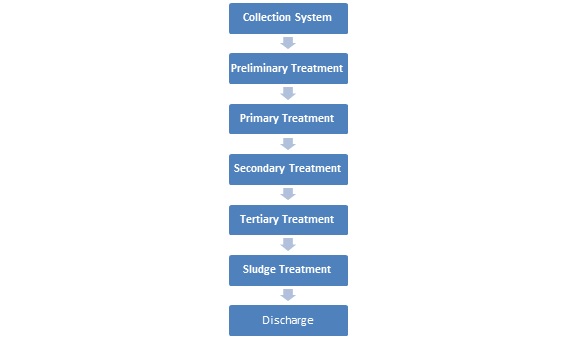

Process Flow Diagram:

The following process flow diagram illustrates the design process for a sewage treatment plant in hilly areas:

Summary:

Designing a sewage treatment plant in hilly areas requires a systematic and efficient approach to overcome the challenges posed by the terrain and variable flow rates. The design process involves several stages, including collection, preliminary, primary, secondary, tertiary, and sludge treatment. The process flow diagram and working function provided in this blog offer a comprehensive overview of the design process, and the formulas used in the design process help to ensure optimal performance of the STP. By following the guidelines and best practices outlined here, we can create an effective sewage treatment plant that can perform better in hilly areas while protecting the natural water bodies from contamination.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.