How to Design a mobile STP?

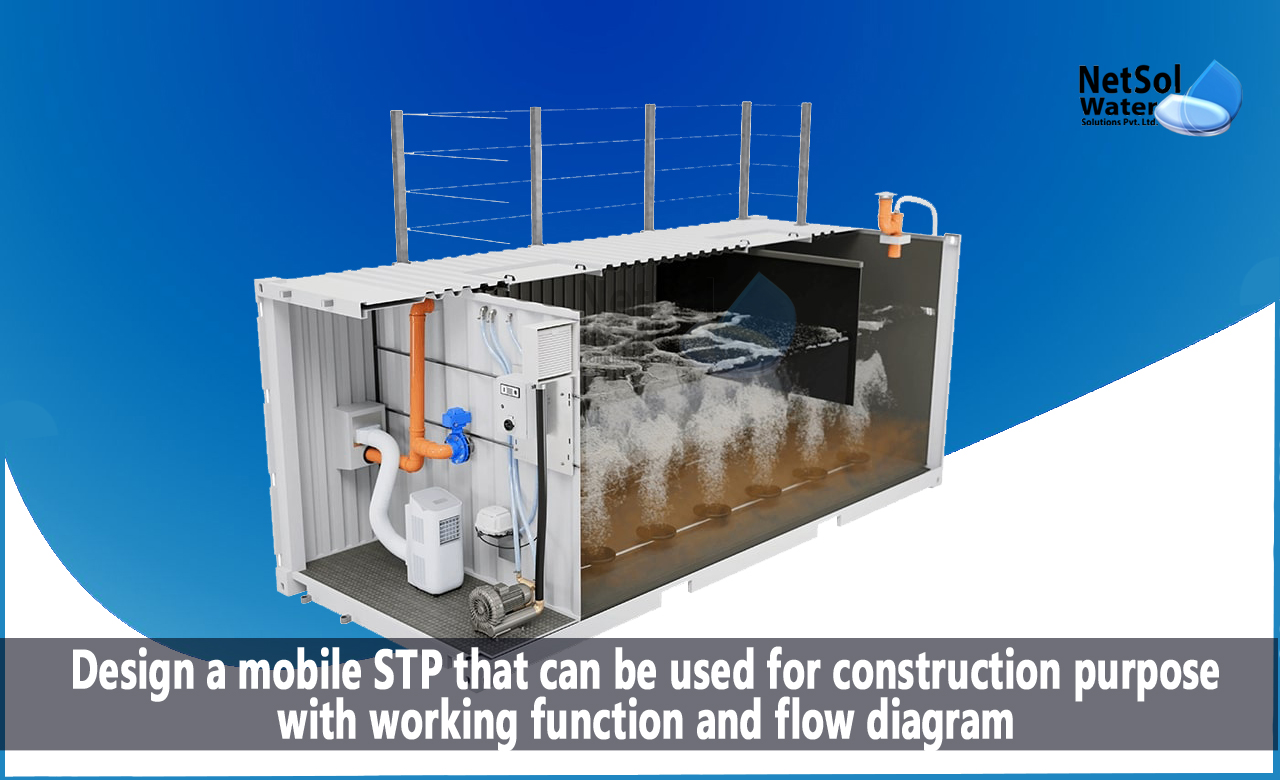

Sewage treatment plants (STPs) are essential infrastructures that help remove pollutants and contaminants from wastewater, making it safe to discharge into the environment. In construction sites, it is essential to treat the sewage water and reuse it for construction purposes. The design of a mobile STP that can treat sewage water and can be used for construction purposes requires careful planning, engineering, and execution to ensure that the plant operates efficiently and effectively.

In this blog, we will discuss how to design a mobile STP that can be used for construction purposes. The STP should treat the sewage water, and the treated water can be used for construction purposes. The same STP can be moved from one place to another if required. We will also provide a detailed process flow diagram and working function for this mobile STP.

Understanding the project requirements:

The first step in designing a mobile STP is to understand the project requirements. This includes determining the expected influent flow rate, quality of the influent wastewater, required effluent quality, and discharge standards set by regulatory bodies. For this mobile STP, the design requirement is to treat 5,000 liters of sewage water per day.

Preliminary design:

The preliminary design involves selecting the appropriate treatment technology and determining the plant layout. For this mobile STP, we have selected a package plant that utilizes a Sequential Batch Reactor (SBR) process. The package plant is designed to fit into a standard shipping container for easy transportation. The layout of the plant is designed to optimize space utilization and provide easy access for maintenance and operation.

Detailed design:

The detailed design involves developing detailed engineering drawings, equipment specifications, and process flow diagrams. The process flow diagram (PFD) for the mobile STP includes the following treatment stages:

![]()

![]()

![]() Screening -> Equalization -> SBR -> Clarification -> Disinfection -> Storage

Screening -> Equalization -> SBR -> Clarification -> Disinfection -> Storage

- Screening: Removal of large solids using a mechanical screen

- Equalization: Balancing the flow rate and organic loading

- SBR: Sequential Batch Reactor (SBR) process where wastewater is treated in a batch process in a single tank

- Clarification: Settling of biological solids using a clarification tank

- Disinfection: Disinfection of treated effluent using UV light

- Storage: Treated water is stored in a tank for reuse in construction purposes

Equipment selection:

The selection of equipment is crucial in ensuring the efficient operation of the STP. For this mobile STP, we have selected high-quality equipment that is compatible with the selected treatment technology and meets the project requirements. Equipment selected for the mobile STP includes a mechanical screen, equalization tank, SBR tank, clarification tank, UV disinfection unit, and storage tank.

Installati?on and commissioning:

The installation and commissioning of the STP require meticulous planning and execution. The mobile STP can be easily transported to the construction site using a standard shipping container. The STP can be connected to the influent sewage line, and the treated water can be reused for construction purposes. Commissioning of the STP involves ensuring that the plant operates as per design specifications.

Conclusion:

In conclusion, designing a mobile STP that can be used for construction purposes requires careful planning, engineering, and execution to ensure that the plant operates efficiently and effectively. A package plant that utilizes an SBR process is an ideal choice for this purpose. The mobile STP can be easily transported, connected to the influent sewage line, and the treated water can be reused for construction purposes. By following these steps, a mobile STP can be designed and executed successfully, meeting the project requirements and regulatory standards.

You may reach us by phone at +91-9650608473 or by email at enquiry@netsolwater.com if you have any questions about our products, services, or support.