Our country's economic and technological advancement is typically credited to the iron and steel sector, as one of the main drivers. It has historically expanded significantly as a result of globalisation and industrialization. Both the usage of steel and water is rising throughout India.

Unfortunately, extensive contamination is also linked to the production of steel. Many procedures, such as cooling, descaling, and dust cleansing, involve the usage of water. The majority of the water is reused or released, so very little of it is really consumed. In contrast to seawater, fresh water is typically used for processing and cooling.

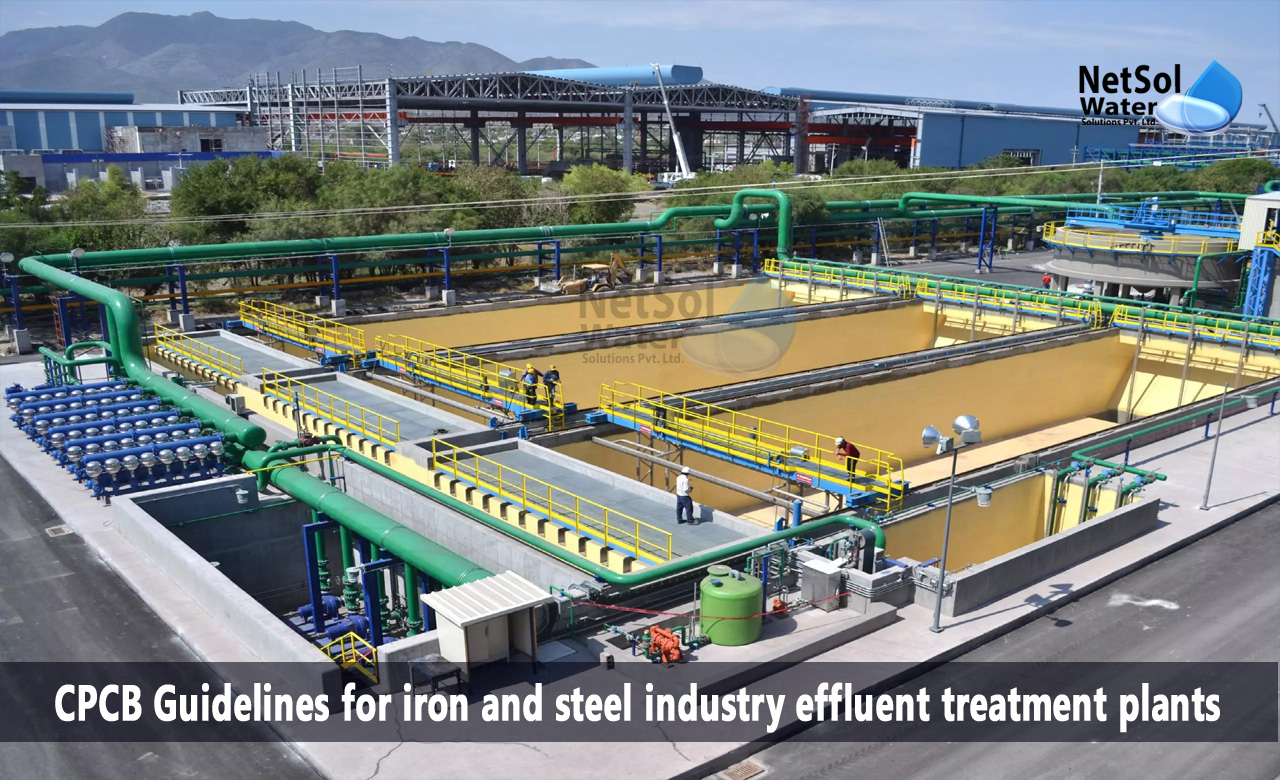

Let's understand the CPCB guidelines for the effluent treatment plants, in the iron and steel manufacturing industries.

Manufacturing Operations

The production processes used in the iron and steel industry can be divided into four categories: rolling mill activities, finishing operations, and the production of pig iron. It is unlikely that a single mill will use all of the various conceivable pairings, and modifications of these activities. Most steel mills produce a wide range of steel products; however, a large mill produces a wide range of products.

The blast furnace serves as the production facility for pig iron. Pneumatic, open-hearth, and electric furnace techniques are all used in the production of steel. Rolling mill processes include rolling blooms, slabs, and billets, scarfing and other semi-finished steel preparations, rolling forms, bars, and plates, drawing wire, drawing tubes, and shaping pipes, as well as pickling and other oxide removal processes. Tin plating, galvanising, cold reduction, and coating are examples of finishing operations.

Use of Water in Industry

Steel factories have a wide range of water needs, which mostly depend on the quantity and quality of the supply. In one situation where water recirculation is widely used, attention has been focused on the usage of as little as 1500 gal of water per tonne of goods, primarily due to a lack of water.

Characteristics of Steel Mill Wastes

In a typical steel mill complex, wastes from the various processes used to make steel differ greatly in terms of their volume and water pollution. These characteristics include TSS, pH, BOD, COD, and others. These wastes typically have distinct physical and chemical effects on receiving streams, than municipal sewage and organic industrial wastes, which tend to consume oxygen.

CPCB Guidelines for iron and steel industry ETP Plants

Composite impacts are of minimal consequence since the waste streams differ so greatly, and are typically separated by the distances between the various operations; treatment and disposal normally need to be taken into account, for the individual wastes.

|

S. No. |

Parameters |

Standards Limiting Concentration in mg/l, except for pH |

|

1. |

pH |

6.0-8.50 |

|

2. |

TSS |

100 |

|

3. |

BOD |

30 |

|

4. |

COD |

250 |

|

5. |

O&G |

10 |

|

6. |

Ammonical Nitrogen as N |

50 |

|

7. |

Cyanide as CN |

0.2 |

|

8. |

Phenol |

1.0 |

How can we assist?

Netsol Water offers a wide range of sophisticated wastewater treatment solutions, such as water softeners, wastewater treatment plants, sewage treatment plants, RO Plants, as well as effluent treatment plants for various industries, including steel mills.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.