What is a trickling filter in wastewater treatment?

Trickling filters, commonly referred to as biological trickling filters, are used to remove organic compounds from wastewater.

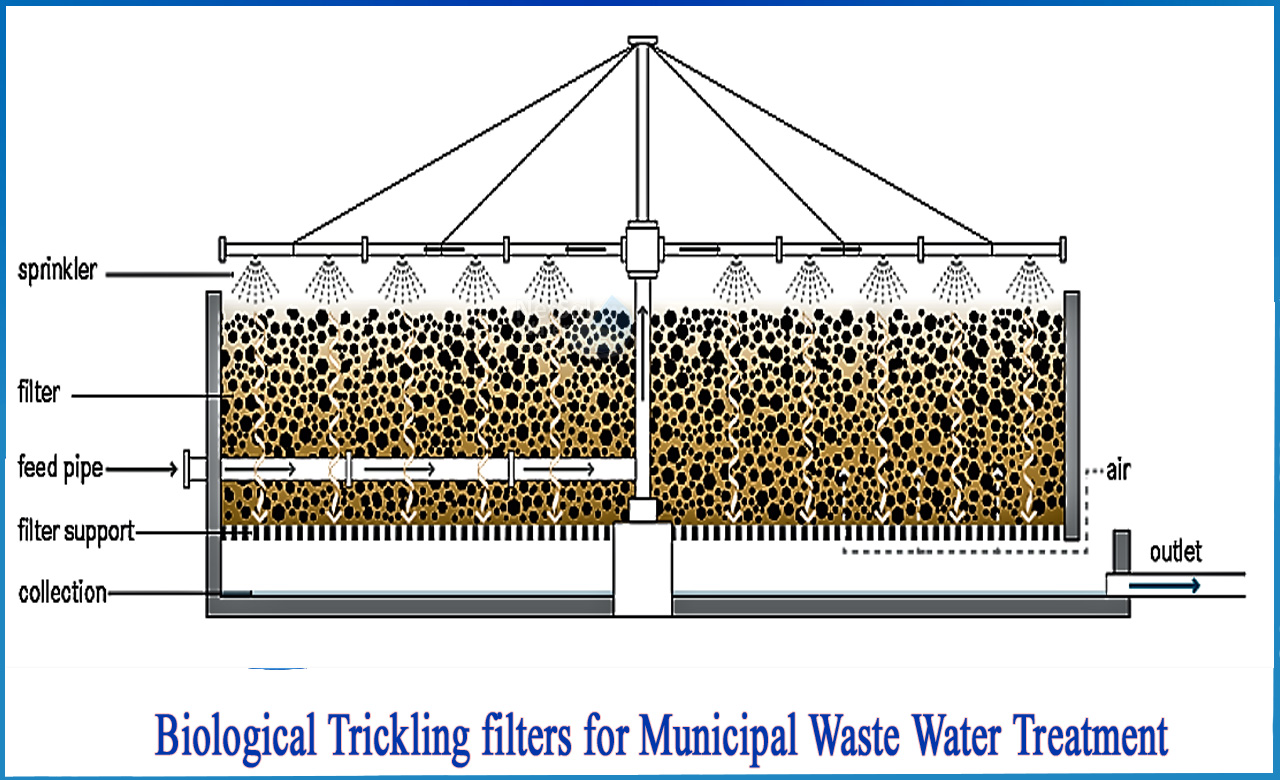

Biological Trickling filters are an aerobic treatment device that removes organic material from wastewater by using microorganisms attached to a media. This mechanism is employed in many different technologies, including rotating biological contactors and packed bed reactors. These processes are known as attached-growth processes. Suspended-growth techniques, on the other hand, are systems that keep microorganisms alive in a solution.

How municipalities uses trickling filters?

In many circumstances, settled sewage reaches a high level and flows into the basic settlement tank. The supernatant from the tank flows into a dosing device, which is often a tipping bucket that distributes flow to the filter's arms. The water flush goes through the arms and exits via a series of downward-pointing holes. This rotates the arms, distributing the liquid uniformly across the surface of the filter material. Most are open to the elements and easily vented to the atmosphere.

Pollutant removal from the waste water stream involves both absorption and adsorption of organic molecules as well as certain inorganic species such as nitrite and nitrate ions by the layer of microbial bio film. Typically, the filter material is designed to have a very high surface area to volume ratio. Typical materials are porous and have a large interior surface area in addition to the medium's outward surface.

The passage of waste water through the medium supplies dissolved oxygen, which the bio-film layer requires for biochemical oxidation of organic molecules, as well as carbon dioxide gas, water, and other oxidised end products. As the secondary sludge develops, the bio film layer sloughs off into the liquid flow and becomes part of it.

To separate and remove the sloughed film, a trickling filter is frequently followed by a clarifier or sedimentation tank. Other filters that employ higher-density media like as sand, foam, and peat moss do not produce sludge and must be cleaned, but they do require forced air blowers, backwashing, or an enclosed anaerobic environment.

Types of biological trickling filters:

Modest home septic tank outputs and extremely small rural sewage treatment systems can be treated using single trickling filters. Many trickling filters are often used in tandem in larger centralised sewage treatment plants.Structure is configured for single-pass operation, in which treated water is applied to the trickling filter once before being discharged, or for multi-pass operation, in which a part of the treated water is cycled back and re-treated via a closed loop.

Multi-pass systems improve treatment quality and help to reduce Total Nitrogen (TN) levels by encouraging nitrification in the aerobic media bed and denitrification in the anaerobic septic tank. Some systems operate the filters in two banks in series, allowing the wastewater to pass through the filter twice, with a sedimentation step in between. To equalise the load, the filters are rotated every few days. Because much of the carbonaceous oxidative material is eliminated on the first pass through the filters, this kind of treatment can enhance nitrification and de-nitrification.

Treatment of industrial wastewater:

Industrial wastewater treatment may entail the use of specialised trickling filters with plastic media and high flow rates. Trickling filters have been used to cleanse wastewater from a range of industrial operations.

There are two kinds of industrial wastewater trickling filters:

· Large concrete cages or tanks filled with plastic packing or other material.

· Vertical towers containing plastic packaging or other media.

For more information on trickling filters, contact Netsol water.