Sugar is a necessary component of human life and one of the most significant dietary substrates. Due to its predominantly seasonal nature, the sugar industry only operates 150–210 days a year (November to May).

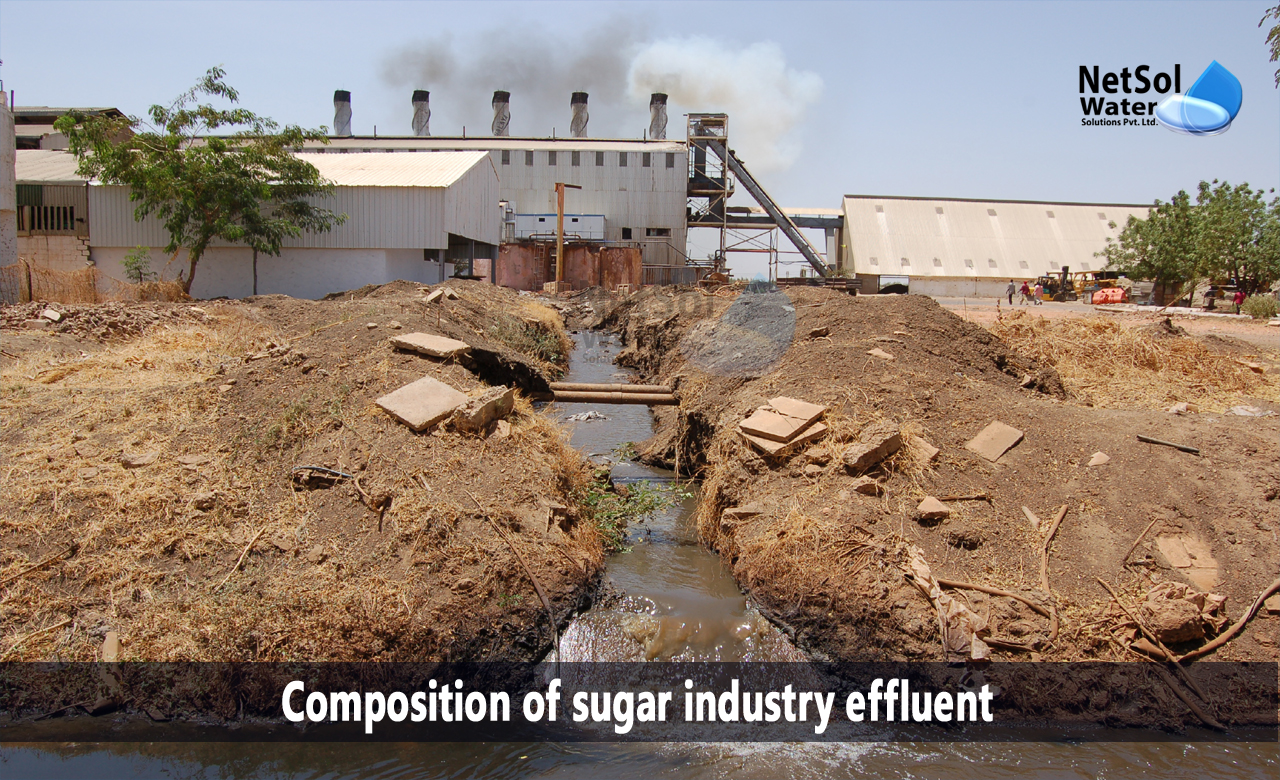

A substantial amount of wastewater is produced during the sugar-making process, and this wastewater is highly polluted, especially in terms of suspended particles, organic matter, press mud, bagasse, and air pollutants.

Wastewater generation in the sugar manufacturing industry

Wastewater is produced in the sugar business when water is utilized for cleaning various parts of the production. Wastewater is created by a number of different processes, including washing on the floor of the milling house, boiling house equipment such as evaporators, clarifiers, vacuum pumps, and centrifugation, among others.

The large volume of wastewater is also as a result of the routine cleaning of homes, which produce lime water and SO2, as well as the routine descaling of heat exchangers and evaporators, utilizing NaOH, Na2CO3, and HCl for heater descaling and neutralization.

Let's examine the makeup/ composition of the effluent from the sugar industry sector, and how it is effectively treated.

What are the Composition of sugar industry effluent?

It is brown in color, have a high temperature, a low pH, a high BOD and COD, a problem with odour, a high level of total solids, and a high level of dissolved organic and inorganic waste.

Untreated wastewater might therefore put the ecology in danger. For every tonne of crushed sugar cane produced by the industry, wastewater production amounts to about 1,000 liters. Wastewater that is not treated pollutes both the terrestrial and aquatic habitats.

Effects of wastewater produced by the sugar manufacturing industry

Industrial wastewater discharges that have not been treated are known to have detrimental effects. Untreated melanoidins, in especially those found in used wash water, can prevent sunlight from reaching water bodies. This reduces photosynthetic activity and oxygen concentrations, which makes it harder for aquatic life to survive.

Additionally, untreated waste water can lower soil alkalinity and dissolved oxygen levels in water bodies, which prevents seed germination in contaminated locations. Therefore, the direct dumping of such wasted wash into water bodies runs the risk of eutrophicating tainted water sources.

Parameters of effluent from sugar industries

The following are the standard metrics for treated wastewater produced by the sugar industry:

|

Before Treatment |

After treatment |

|

|

pH |

4-6.5 |

6.5-8.5 |

|

Colour |

Brownish |

Nil |

|

Odour |

Present |

Nil |

|

TSS |

500-600 mg/l |

<300 mg/l |

|

Oil and grease |

10-50 mg/l |

<10 mg/l |

|

Total solids |

5000-6000 mg/l |

<2000 mg/l |

|

COD |

2000-3000 mg/l |

<250 mg/l |

|

BOD |

1000-1200 mg/l |

<100 mg/l |

Conclusion

Environmental engineers find it difficult to clean and make use of the complicated, effluent from the sugar sector. Prior to treatment and recycling, it is vital to determine the physicochemical parameters.

What do we offer?

One of India's top producers of wastewater treatment systems for the sugar industry is Netsol Water. Contaminants are present in high concentrations of effluent from the production of sugar. In order to dispose of sugar mill effluent into water bodies safely and securely, or to reuse it in compliance with legal requirements, it must be treated.

Together with our customers, we develop a specialized water treatment solution that satisfies their individual needs, as well as an ongoing service plan to fully maintain their system.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.