What is anaerobic wastewater treatment?

Anaerobic wastewater treatment is a biological process of degradation of organic contaminants by microorganisms in the absence of oxygen.

In anaerobic treatment cycle, wastewater enters a bioreactor receptacle which contains a thick, semi-solid substance known as sludge, comprising of anaerobic bacteria and other microorganisms. These microorganisms, or “anaerobes,” digest the biodegradable matter present in the wastewater, resulting in a wastewater with lower biological oxygen demand (BOD), chemical oxygen demand (COD), and/or total suspended solids (TSS), as well as biogas byproducts.

Anaerobic treatment is used for treatment of industrial effluent streams from agricultural, food and beverage, pulp and paper, and textile industries, as well as municipal wastewater. Anaerobic technologies are specifically deployed for wastewater with high concentrations of organic content.

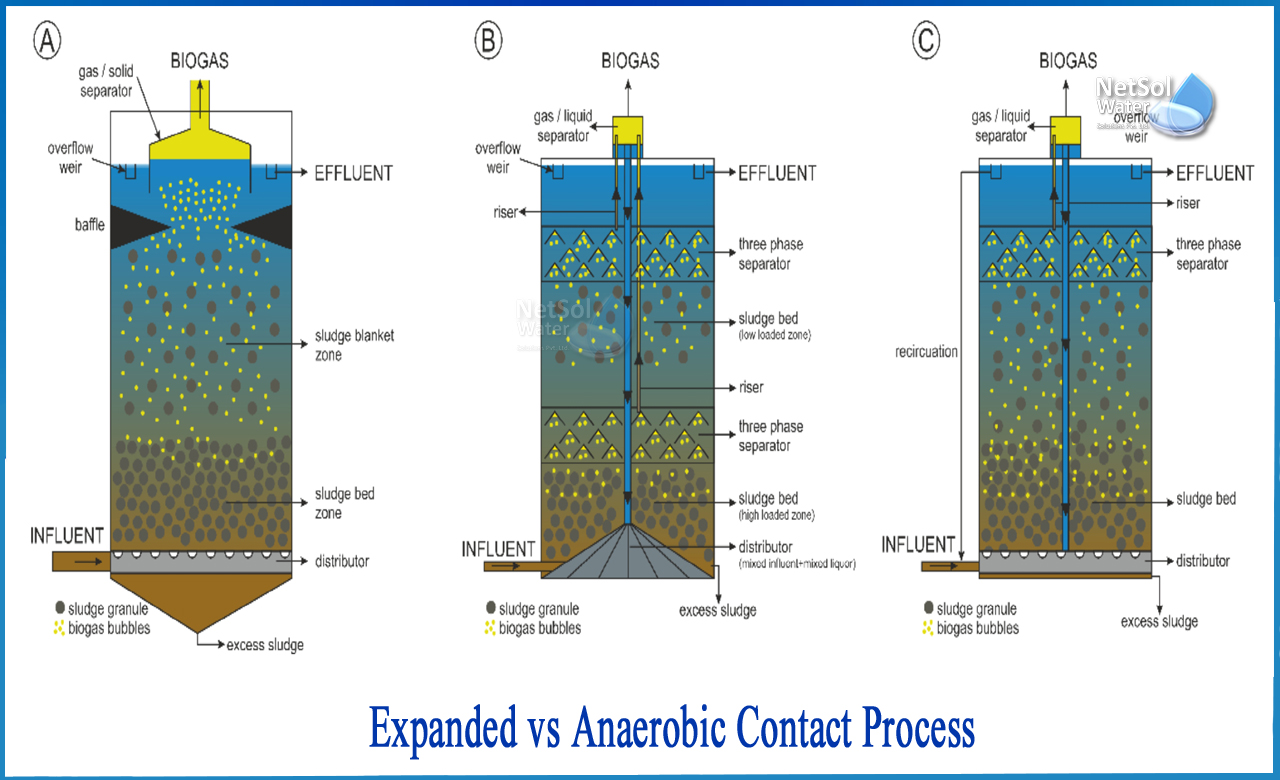

What are the difference between Expanded and Anaerobic process?

Depending upon application needs and facility requirements, anaerobic digester systems can be designed as single- or multi-stage units, i.e., they can be configured with a separate acidification tank and bioreactor unit.

Improved understanding of mixing and mass transfer, and anaerobic reactor design, led to advances of high rate anaerobic processes like:

Anaerobic Filters (AF), Anaerobic Expanded bed reactors, lagoon, Plug-flow anaerobic digester, Two-stage anaerobic digester, anaerobic contact process, Upflow anaerobic sludge blanket digestion (UASB) and Upflow and down-flow anaerobic attached growth systems.

This article will provide an approachable introduction to expanded bed process and anaerobic contact process.

What is Expanded Bed Process?

The development of expanded bed anaerobic reactors eliminates the problems inherent to the stationary bed processes. In the expanded bed process, the biomass grows into reduced thickness films, attached to small sized particles. The expansion of medium eliminates blockage problems, besides increasing the biomass retention and its contact with the substrate, thereby significantly reducing the hydraulic retention times in the reactors.

In the expanded bed process, the wastewater to be treated is pumped upward through a bed of appropriate support medium including sand, coal, gravel, expanded aggregate, PVC etc., on which a biological growth has been developed.

Expanded bed reactors consists of a cylindrical structure packed with inert support medium. Effluent is recycled to dilute the entering wastewater and to maintain a sufficient flow to keep the bed extended. The biofilm grows on to the particles that are expanded by the liquid's upward movement. It is possible to get biomass concentrations of 15,000 to 40,000 mg/L. Since more biomass can be maintained, the expanded bed process can also be used for the treatment of low concentration sewage, with minimum hydraulic retention times. Organic loading in the range of 5 to 10 kg COD/ m3.d can be applied with COD removal efficiencies of about 80 to 85 %. The hydraulic retention time generally is in the range of 5 to 10 hours.

What is Anaerobic Contact Process?

The washout of the active anaerobic bacterial mass from the reactor is regulated by a sludge separation and recycling system, which is a key aspect of the anaerobic contact process. The separation (and concentration) of the sludge from the effluent solution has always been a major issue in the practical implementation of the contact process.

Several procedures, such as plain sedimentation, settling mixed with chemical flocculation, vacuum degasification, flotation, and centrifugation, have been employed or advised for this purpose. The contact process is based on the premise that completely mixing the digester contents is required, such as by gas-recirculation, sludge-recirculation, or continuous or intermittent mechanical agitation. This is commonly used to treat concentrated wastewater, such as that from distilleries.

How can Netsol help?

Netsol Water have expertise in wide range of waste water treatment technologies. We can customize wastewater treatment plants that will cater to all your needs and at the same time, effectively treat different types of wastewater. We are dedicated to provide hands on service, expert counselling and training to our valuable customers.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.