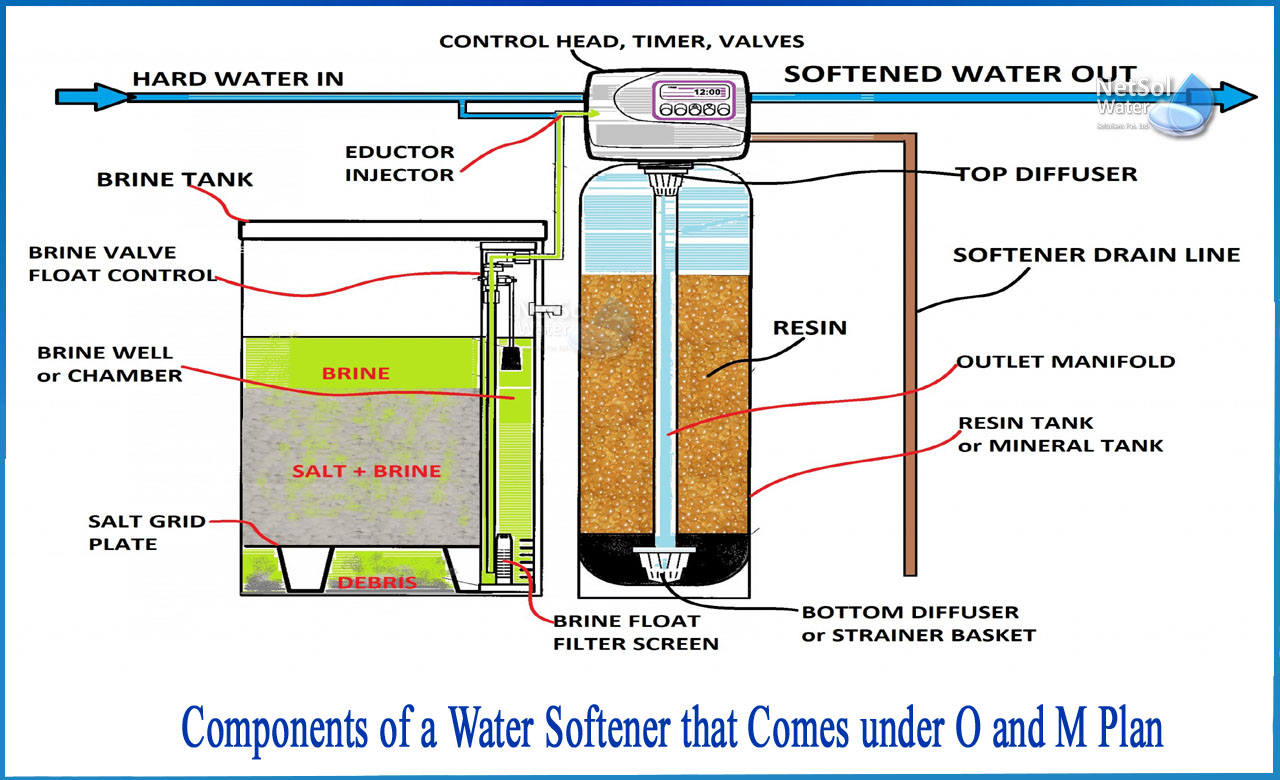

What are the components of a water softener under O and M Plan?

Most Softener failures can be avoided with a strong preventative maintenance strategy!

Softener systems are now used for a variety of purposes, ranging from basic water conditioning to industrial ingredient water. The softening function is controlled by a few valve manufacturers, and many agree that having a preventative maintenance plan in place can assist minimize unplanned failures or downtime.

The majority of institutions test their softener systems once a shift or on a daily basis. That's a good technique for determining if your softener system is working or not, but it doesn't necessarily reveal all potential issues.

A comprehensive preventative maintenance plan can aid in the prevention of problems. While this service can be done in-house, having an experienced technician on hand can be incredibly beneficial.

Water softener components covered by the O&M Plan-

1: Valve Wear and Tear Evaluation

The condition of your Water Softener's valves will be inspected during preventative maintenance by your skilled Water System experts. Internal parts are removed to check for wear and tear and, if necessary, are replaced.

The faulty valve may be replaced by an experienced professional to get your commercial water softener back up and running.

2: Study of Brine

A brine study on your facility's water is generally performed by the expert who comes to inspect your Water Softener to determine how much salt is being introduced into the water. A brine study can tell you whether or not your softener is working properly. The technician can make adjustments to improve the brine concentration and provide effective softening if not enough salt is getting into the water.

3: Replacement or rebuild of the solenoid

The Water Softener's solenoid valve doubles as a water metre and a flow restrictor. It controls the flow of water by turning it on and off in accordance to predetermined flow rates. To provide proper water flow regulation, a technician can repair or rebuild solenoids.

4: Pilot Screens that need cleaning

Industrial Water Softeners pilot screens might become blocked with build-up or valve corrosion chips over time. The blockage of the pilot line and the multiport valve can cause problems. It's possible that the brine tank will overflow, making the cycles appear shorter.

5: Lubrication

Many moving parts, such as softening pistons and valve shafts, are included in the industrial Water Softener design. Lubrication on these critical components keeps them moving smoothly, allowing the softener to work at its best. It decreases friction to reduce wear and tear on these components, extending the life of the pistons or shafts and reducing the need for maintenance and replacement.

6: Inspections by sight

Your water system specialist will most likely undertake a thorough visual assessment of the softener as part of routine maintenance. The technician can assess the status of important components to spot problems and upgrade opportunities.

Several evaluative aspects are commonly included in a visual inspection of a Water Softener:

Checking for leaks in components: The technician can repair or replace broken parts before minor leaks turn into severe problems needing extensive repairs.

Checking the brine tank level: A high water level in the brine tank usually indicates a leaking brine valve. Before the brine valve malfunctions and overfills the tank, producing extra salt dissolving and waste outflow, a technician should remedy this issue.

Checking pressure gauges: The technician should inspect the pressure gauges on the input and outflow of the industrial water softener.

Evaluating the control valves: An industrial Water Softener's electronic controllers provide a plethora of relevant system information. The technician should also look for signs of wear and tear on the control valves.

Examining the drain: The drain can reveal leaks and resin degradation.

7: Testing of Resin

Hiring an expert to test your resin will help you establish how long it has left to live, as well as discover any foulants.

8: Backwash Flow Controllers Inspection

Backwash flow controllers should be checked and cleaned to ensure that there is enough flow for backwash and no limits for brine.

9: Measuring Resin Concentration

Checking the resin level in the softener might help you figure out if you have enough resin.

10: Pressure gauges for monitoring

The pressure gauges in your industrial water softener must be checked on a regular basis as part of routine maintenance.

11: Installing a Compound Gauge

Installing a compound pressure gauge that shows both pressure and vacuum helps ensure that your commercial water softener is operating properly.

12: The Brine Tank needs cleaning

Cleaning the brine tank once a year can assist with adequate brine injection.

What do we have to offer?

If you want to know more about the components of Water Softener that comes under O&M, then you are at the right place!

You can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.