Common Maintenance Activities and Troubleshooting for MBBR Systems

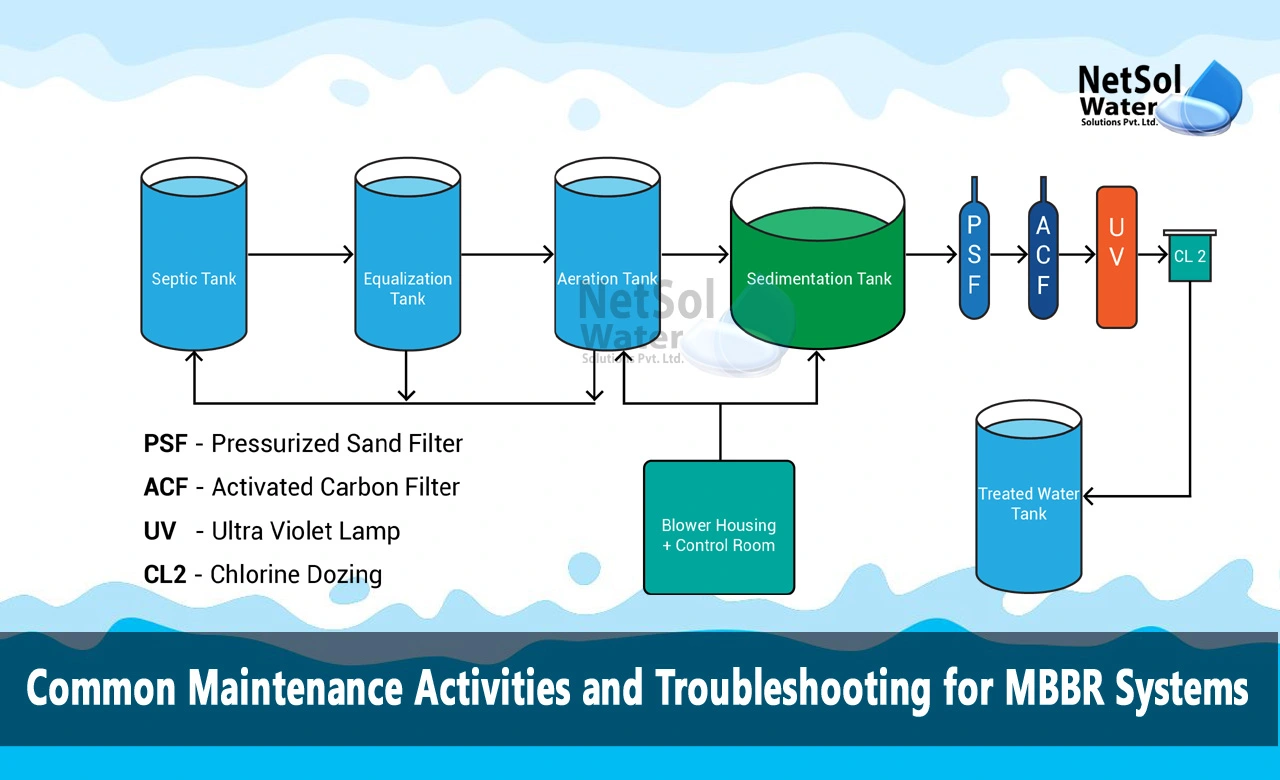

Moving Bed Biofilm Reactors (MBBRs) have become an increasingly popular wastewater treatment technology in recent years. MBBRs utilize specialized plastic carrier media on which a biofilm grows to treat organic matter and other contaminants in wastewater through a robust biological process. The small carrier elements are continuously mixed and aerated to provide optimal conditions for the biofilm to thrive. Compared to conventional activated sludge systems, MBBRs provide efficient treatment, compact footprint, and lower sludge production.

However, like any complex treatment system, MBBRs require diligent maintenance and monitoring to sustain optimal performance. Regular upkeep activities along with prompt troubleshooting of any emerging issues are essential to the longevity and effectiveness of these systems. Skilled operators who implement the necessary preventative maintenance steps and respond appropriately to upsets are invaluable to smooth and reliable MBBR operation. This blog provides an overview of common maintenance activities and troubleshooting for MBBR systems.

Regular Maintenance

1- Media replacement: The plastic carrier media in MBBRs needs to be replaced periodically as it degrades over time. Typical media replacement frequency is every 5-10 years.

2- Aeration system maintenance: Diffusers, blowers, and other aeration components should be inspected and serviced regularly to ensure proper oxygen transfer to the wastewater.

3- Foaming control: Excessive foaming can be an issue in MBBRs. Chemical anti-foaming agents or foam breakers may need to be added periodically.

4- Removal of excess biomass: Excess biofilm can slough off and accumulate in the MBBR requiring periodic wasting of biomass.

5- Monitoring/testing: Regular monitoring of parameters like BOD, COD, nutrients, pH, etc. is necessary to ensure the MBBR is working optimally.

Troubleshooting Common Issues

1- Poor treatment performance: This may be due to insufficient aeration, media clogging, excessive biomass growth, or hydraulic issues. Troubleshooting involves checking aeration system, monitoring biofilm thickness, and inspecting for solids accumulation or plugging.

2- Odor/Air issues: Excessive odors coming from the MBBR may indicate septic conditions, insufficient aeration, or build up of sulfur compounds. Ensure proper aeration and monitor dissolved oxygen levels.

3- Media floating: Excess gas production can cause media to float. Reduce Organic Loading Rate (OLR) and ensure proper solids management. Increase aeration if needed.

4- Foaming: As mentioned earlier, anti-foams can treat excess foaming. Identify and reduce causes of high foam like high grease content.

5- Mechanical issues: Malfunctioning mechanical parts like blowers, pumps, mixers, etc. need immediate troubleshooting and repair

Conclusion

Proper maintenance and troubleshooting are critical to ensuring efficient and effective operation of Moving Bed Biofilm Reactors. Routine maintenance activities like replacing the plastic media on a 5-10 year cycle, inspecting and servicing aeration components, controlling foaming with chemical additions, and wasting excess biomass are essential preventative measures. Additionally, regularly monitoring and testing key parameters provides important insight into the health and performance of the MBBR system.

When issues do arise, timely troubleshooting and problem-solving can get the system back on track quickly. Common problems like poor treatment performance resulting from insufficient aeration, hydraulic problems, or excessive growth need immediate attention. Similarly, operational issues like odor, floating media, and excessive foaming must be addressed through corrective actions like increasing oxygen levels, reducing organic loading, and anti-foam additions. Mechanical malfunctions in blowers, pumps, mixers, and other equipment necessitate urgent troubleshooting and repairs as well.

By staying vigilant through routine maintenance and monitoring, potential issues can be caught early before they escalate. When problems occur, methodical and thorough troubleshooting is needed to identify the root causes and implement targeted solutions. Well-trained operators who understand the MBBR system and respond appropriately are essential.

Do you need an advice or assistance on selecting the best water and wastewater treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com