Commercial RO (reverse osmosis) filters are water filtration systems designed for use in commercial and industrial settings. These systems are capable of treating large volumes of water and are used in a variety of applications, including drinking water production, food and beverage processing, pharmaceutical production, and more.

In this blog, we will discuss in detail the working of RO filters in army camps.

Why do army camps need RO filters systems?

Army camps require RO (reverse osmosis) filter systems for several reasons:

1. Safety: Clean and safe drinking water is essential for the health and well-being of military personnel. RO systems can remove contaminants, bacteria, viruses, and other impurities from water, making it safe for consumption.

2. Mobility: Army camps are often situated in remote areas where access to clean drinking water is limited. RO systems can be easily transported and set up in these locations, providing a reliable source of clean water.

3. Dependability: RO systems can operate in a variety of environmental conditions and are highly reliable, ensuring a constant supply of clean drinking water.

4. Cost-effective: RO systems can provide a cost-effective solution for providing clean drinking water, especially in areas where the cost of transporting bottled water is high.

5. Sustainability: RO systems can be used to treat and reuse wastewater, reducing the need for freshwater sources and promoting sustainability.

Commercial RO filter for army camps with flow chart and working:

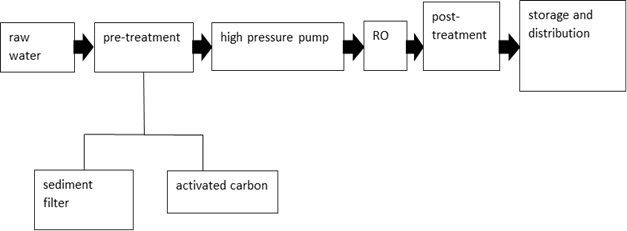

Commercial RO filter systems for army camps are designed to provide clean and safe drinking water for military personnel. Here is a flow chart and working of a typical commercial RO filter system for army camps:

1. Raw water: The first step in the process is to obtain water from a source such as a well, river, or municipal supply.

2. Pre-treatment: The water is pre-treated to remove any large particles, sediment, or debris that may be present. This can involve using a series of filters such as sediment filters, activated carbon filters, and other pre-treatment equipment.

3. High-Pressure Pump: The pre-treated water is then pumped at high pressure using a high-pressure pump. The pressure helps to force the water through the RO membrane.

4. Reverse Osmosis: The water is passed through a semipermeable RO membrane, which removes impurities and dissolved solids from the water. The RO process involves a series of stages, including the feed stage, concentrate stage, and permeate stage.

5. Post-treatment: After the RO process, the water is passed through a series of post-treatment steps, which can include disinfection using UV light, mineralization, pH adjustment, and other treatments to improve the quality and taste of the water.

6. Storage and Distribution: The treated water is then stored in a clean, disinfected tank and distributed to various points of use throughout the army camp.

Conclusion:

The working of a commercial RO filter system for army camps involves multiple steps to ensure the safety and quality of the treated water. The pre-treatment step removes large particles and sediment, while the RO process removes dissolved solids and impurities. Post-treatment is then used to further purify and improve the taste of the water. Finally, the treated water is stored and distributed for use throughout the army camp.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com