What are steps involved in the industrial waste water treatment?

The procedures used to treat wastewater produced as an unwanted by-product by industry are referred to as industrial wastewater treatment. The treated industrial wastewater (or effluent) can be reused or discharged into a sanitary sewer or surface water in the environment after treatment. Sewage treatment plants can treat wastewater generated by some industrial facilities.

Most industrial processes, such as petroleum refineries, chemical and petrochemical plants, have their own specialised facilities for treating their wastewaters so that pollutant concentrations in the treated wastewater meet the regulations for wastewater disposal into sewers, rivers, lakes, or oceans. This is true for enterprises that produce wastewater containing large levels of organic matter (e.g., oil and grease), hazardous pollutants (e.g., heavy metals, volatile organic compounds), or nutrients (e.g., ammonia). Some businesses use a pre-treatment system to remove some contaminants (such as hazardous chemicals) before discharging the partially treated waste.

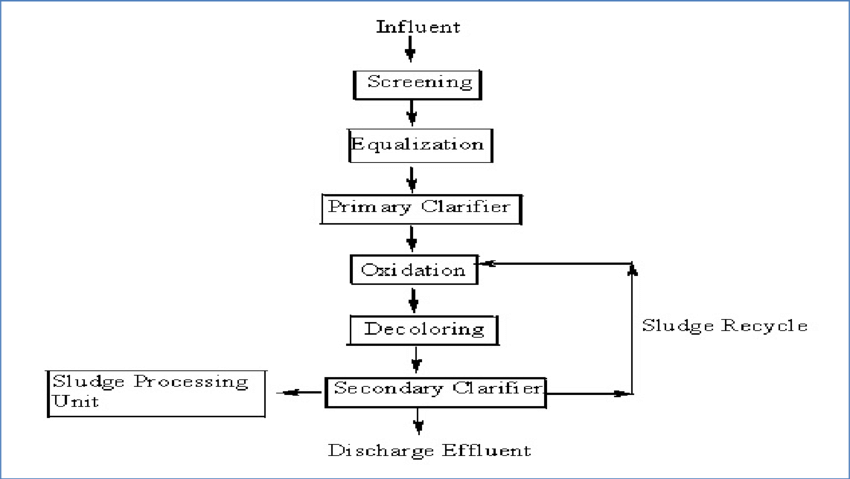

Following are the stepwise procedures employed along with the flowchart:

Step 1: Screening and pumping

Objects such as rags, wood bits, plastics, and grease are removed from the incoming wastewater by screening machinery. The extracted material is washed and pressed before being disposed of in a landfill. The grit-removal phase is next performed on the screened wastewater.

Step 2: Getting Rid of the Grit

Heavy yet fine debris like sand and gravel is removed from the effluent in this step. This waste is also thrown away at a landfill.

Step 3: Primary Settling

Large circular tanks called clarifiers are used to remove the material, which will settle but at a slower rate than in step two. The settled material, referred to as primary sludge, is pushed out of the bottom of the tank, while the wastewater exits from the top. Floating debris, such as grease, is skimmed off the top and transported to digesters together with the settled material. Chemicals are also applied at this point to eliminate phosphorus.

Step 4: Aeration / Activated Sludge

The wastewater receives the majority of its treatment in this step. The contaminants are absorbed by microorganisms and turned into cell tissue, water, and nitrogen through biological breakdown. The biological activity that occurs in this step is quite similar to that which occurs at the bottom of lakes and rivers, but the degradation takes years in these locations.

Step 5: Subsequent Settling

At this step, large circular tanks known as secondary clarifiers allow the treated wastewater to separate from the biological waste in the aeration tanks, resulting in an effluent that is now over 90% treated. Step four involves continuously pumping the biology (activated sludge) from the bottom of the clarifiers and returning it to the aeration tanks.

Step 6: Filtration

This process polishes the cleared effluent by filtering it through 10 micron polyester medium. The material gathered on the disc filters' surfaces is backwashed and returned to the plant's head for treatment on a regular basis.

Step 7: Disinfection

After the filtration phase, UV disinfection is employed to ensure that the treated wastewater is virtually bacteria-free. The ultraviolet treatment process destroys any germs left over, bringing us back into compliance with our discharge permit.

Step 8: Oxygen uptake:

If necessary, the treated water is aerated to bring the dissolved oxygen content up to the permissible level. After this, the treated water is discharged into the river via the effluent outfall.

Step 9: Treatment of Sludge:

The waste activated sludge from the aeration/activated sludge process in step four, as well as the primary sludge pumped from the bottom of the primary clarifiers in step three, must be treated to reduce volume and generate an useful end product.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.