Why is industrial wastewater treatment a basic requirement?

With expanding population, urbanization, and industrialisation, along with river basin closures, India is left with extremely water stressed regions and the inability to manage its water resources properly. As a result, by 2025, the average per capita freshwater availability is anticipated to fall to 1241 m3. It is also anticipated that by 2025, about 29.3 billion cubic meters of water would be required for home and industrial reasons. As a result, efficient and cost-effective biological treatment of industrial wastewater and reuse have emerged as a promising alternative for meeting future water demands.

In India, industries create roughly 13,368 MLD of wastewater, of which only 60%, primarily from large-scale industry, is treated every day.Small-scale enterprises' industrial effluent is frequently not treated to the specified requirements. Thus, urgent novel solutions are required to improve India's industrial wastewater treatment process.

Industrial Wastewater Components

The content of effluents might vary depending on the kind of industrial business. Ammonia, acids, heavy metals, calcium ions, detergents, paints, organic matter, solvents, lipids, cellulose, food wastes, and other contaminants are commonly present in industrial effluent that requires treatment.

Because a substantial amount of industrial wastewater ends up in the environment, enterprises must effectively treat effluents to fulfil the mandated criteria.

The following are the primary industries that require treatment:

1)Food and Beverage: Wastewater created in the food and beverage sectors comprises significant levels of nutrients, organic carbon, and organic particle matter. Wastewater from dairy enterprises may contain significant levels of fats, oils, and grease, as well as whey liquid, which must be properly separated and treated.

2) Pulp and paper: The bleaching step generates approximately 85 percent of the total effluent from this industry, with effluent loadings varying depending on the raw materials. It is made up of variable amounts of organic and inorganic components. The most prevalent wastewater treatment techniques used in the paper industry are activated sludge treatment and aerated ponds.

3)Oil and Gas and Petrochemicals: Pollutants in wastewater created by the petroleum sector include a wide range of substances including hydrocarbons, mercaptans, oil and grease, phenol, ammonia, and sulphides.

4)Healthcare (Hospitals): Most hospital effluents are discharged into sewer systems or processed at an on-site sewage treatment facility before being released into the environment. However, poor treatment of this effluent might impair human health since it contains pharmaceutically active substances, antibiotic-resistant genes, viruses, and a high BOD and COD concentration.

5)Chemical Manufacturers: Wastewater from this business comprises extremely harmful contaminants as well as organic and inorganic wastes in various concentrations.Materials emitted can be poisonous, carcinogenic, and mutagenic, necessitating extensive treatment prior to release.

6)Drugs and Pharmaceuticals: Wastewater from these businesses may include pharmaceutically active chemicals that have inherent biological activity. Without adequate management, its presence in the environment can lead to the growth of antibiotic-resistant bacteria, increased toxicity of chemicals, and negative impacts on human and aquatic health. Individual API or drug recovery, aerobic/anaerobic biological treatment, inactivation of active compounds by UV oxidation, or basic physical-chemical treatment procedures are common options for wastewater treatment.

7)Distilleries and Breweries: The majority of breweries release around 70% of their entering water as effluent.Brewery effluent has a high moisture content and high BOD and COD levels owing to organic components such as sugar, starch, and fatty acids.

Conclusion

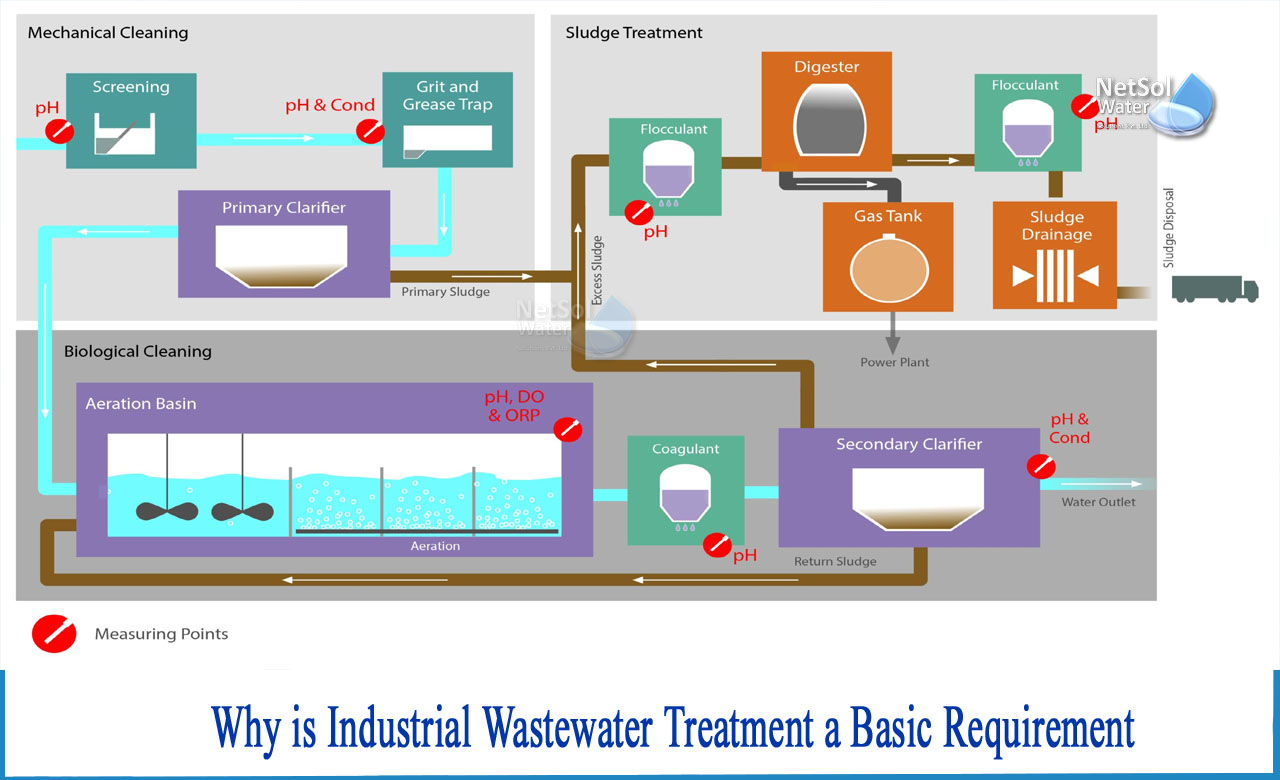

The wastewater treatment solutions offered by Netsol Water are a tried-and-true solution for successful sewage and industrial wastewater treatment. Our wastewater treatment systems are specially developed to successfully and significantly decompose organic waste and are aimed at a wide range of industry and municipal authorities. Netsol may drastically reduce sludge volume, operational expenses, bad odour, and COD and BOD levels in industrial wastewater, as well as enhance the treatment process.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.