When the untreated edible oil refinery effluent is released into the environment, it is regarded as the most dangerous waste. The effluent from edible oils is a yellowish liquid with high levels of dissolved solids, oil and grease, high COD and BOD values, low pH, and high levels of total phosphorus, ammonia nitrogen, and kjeldahl nitrogen.

High organic loading and biodegradable chemical waste streams are treated, using the activated sludge technique. The biological treatment of wastewater, from edible oil refineries, is the most popular method for the treatment of wastewater. Sequencing batch reactor is also a successful adaptation of the activated sludge method, for the treatment of wastewater from edible oil refineries.

Sources of wastewater from edible oil refineries

Wastewaters from degumming, de-acidification, deodorization, and neutralisation processes, are the main sources of wastewater in the edible oil sector. The neutralisation process involves the production of sodium salts of free fatty acids (soap stocks), whose breakdown with H2SO4 results in extremely acidic and greasy wastewaters. Its features are mostly determined by the type of oil treated and the process used, which are high in COD, oil and grease, sulphate, and phosphate content, resulting in both high inorganic and organic loading of the necessary wastewater treatment.

Characteristics of the influent and standard values of the wastewater generated, in edible oil refineries

|

S. No. |

Parameter |

Influent |

|

1. |

Color |

Yellowish |

|

2. |

pH |

2.0±0.8 |

|

3. |

Temperature, 0C |

35±1 |

|

4. |

Total Dissolved solids |

4800±2.0 |

|

5. |

Oil and Grease, mg/l |

150±1.0 |

|

6. |

BOD5 (20 0C) , mg/l |

359±11.0 |

|

7. |

COD, mg/l |

7000±8.0 |

|

8. |

TKN mg/l |

6.08±0.5 |

|

9. |

Phosphate, mg/l |

57.4±0.8 |

|

10. |

Sulphate, mg/l |

2.0±0.2 |

|

Parameter |

Guideline Value |

|

pH |

6-9 |

|

Temperature increase, 0C |

<3° |

|

Total Suspended solids, mg/l |

50 |

|

Oil and Grease, mg/l |

10 |

|

BOD5 (20 0C) , mg/l |

50 |

|

COD, mg/l |

250 |

|

Total Nitrogen mg/l |

10 |

|

Total Phosphorus, mg/l |

2 |

|

Total coliform bacteria, MPN/100ml |

400 |

Biological treatment of wastewater from edible oil refineries

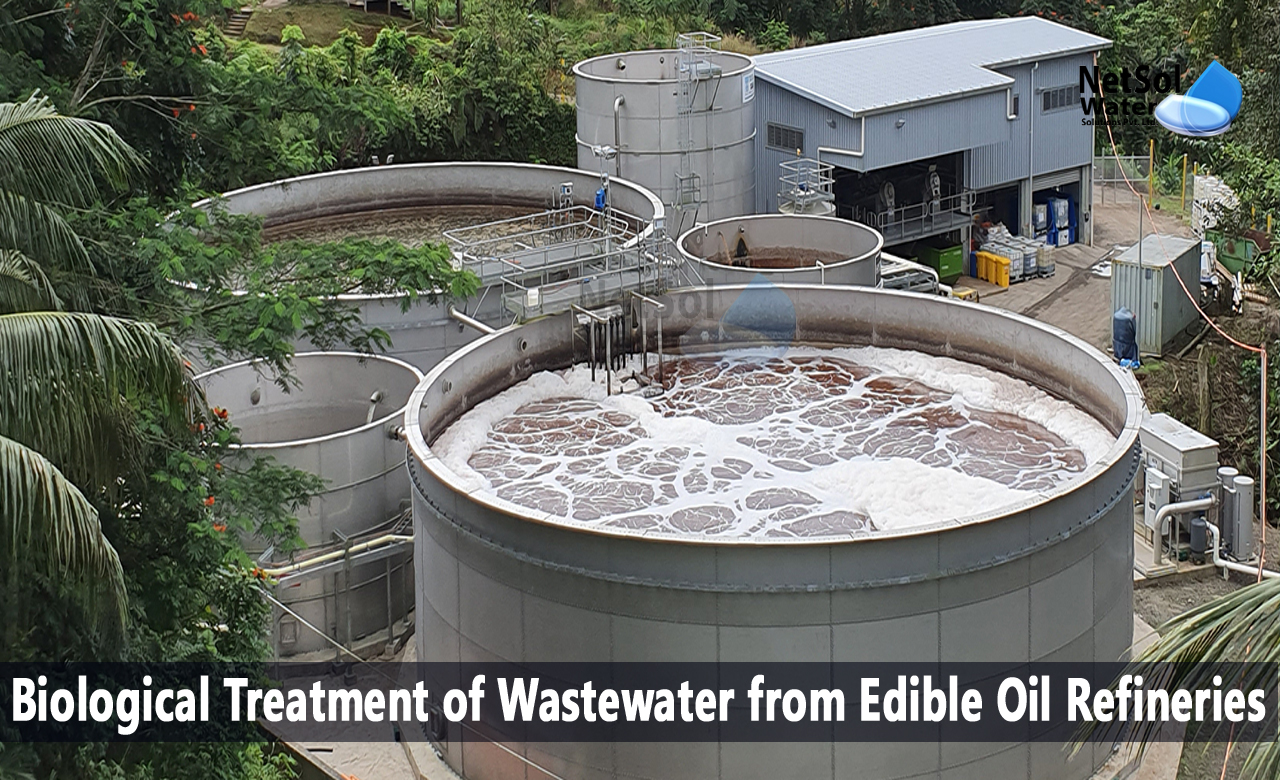

The effluents from edible oils can be handled chemically or biologically, separately or together. Chemical treatment issues include rising chemical handling expenses, and the creation of difficult-to-treat and-dispose-of chemical sludge. In the treatment of edible oil effluent, biological treatment methods provide a quick and affordable alternative. Wastewater from edible oil production could be biologically treated, using a sequencing batch reactor and the conventional activated sludge process.

Process of Activated Sludge

High organic loading and biodegradable chemical waste streams are treated using the activated sludge technique. Historically, the study of fills and draws reactors marked the beginning of activated sludge technology. The original activated sludge plant was actually a sequencing batch reactor, where sewage was added to the reactor in batches over the course of a set amount of time. Following a certain amount of time spent aerating the reactor's contents, the sludge flocs were allowed to settle and the supernatant liquor was decanted.

Components of ASP in an edible oil refinery

The edible oil refinery effluent treatment plant (ETP) in the typical activated sludge process, is made up of the following units: an equalisation basin, a neutralisation unit, a clariflocculator, a primary clarifier, an aeration basin, a secondary clarifier, and a filter press.

For the unit processes of biological reaction (aeration of mixed liquor) and solids-liquid separation (clarification), conventional activated sludge systems call for separate tanks. They also mandate that process mixed liquor solids (return activated sludge), be returned from the final clarification stage to the aeration tanks.

Only the removal of COD, BOD, TSS, and faecal coliforms as well as an improvement in pH, DO recovery, and TKN and phosphate up to a certain limit, make the activated sludge process possibly viable for treating edible oil refinery wastewater.

Sequencing Batch Reactor Process

It is the mixed-culture, suspended growth activated sludge treatment technology. SBR technology is a technique for treating wastewater, in which each stage of the treatment process happens in turn inside the same tank. Less civil infrastructure, connecting piping, process equipment, and resulting reductions in capital and operational expenses, are hence the key advantages of SBR systems.

Components of SBR System

A single or a number of reactor tanks that operate in tandem may make up an SBR system. A SBR reactor's operational cycle is divided into five separate phases: FILL, REACT, SETTLE, DRAW, and IDLE.

Benefits of Activated Sludge Process or ASP

Firstly, for the biological treatment of wastewater from edible oil production, conventional ASP is appropriate. Industrial wastewater is treated using the activated sludge technique, although, it is only used to remove COD, BOD, TSS, Fecal coliforms, and to improve pH and DO recovery, as well as to some extent reduce TKN and phosphate.

Secondly, reducing the number of running cycles can cut operational costs by 3%. By using a smaller capacity air blower for the traditional activated sludge wastewater treatment system, operational expenses might be reduced by 12%.

Finally, BOD removal efficiency is found to be 94.56%, and TSS removal efficiency is found to be 93.72%.

Benefits of Sequencing Batch Reactor or SBR

Firstly, the benefits of SBR technology include control over the microbial population, flexibility in operation, ease of expansion, viability of operation at low retention times, and a variety of reactor configurations. A very high percentage of BOD, COD, total dissolved solids, and suspended solids are removed.

Secondly, the control and flexibility of the SBR process are two important benefits. The "respond" time can be changed to suit process goals, because it is not flow dependant. Alternative aerobic and anoxic reactor conditions can be produced, for the removal of nitrogen and phosphorus, by adjusting the oxygen supply and mixing regime.

Thirdly, one reactor vessel may achieve equalisation, primary clarity, biological treatment, and secondary clarification, with little need for additional space thanks to the SBR process.

Finally, utilizing an internal carbon source has the main benefit of utilizing fewer chemicals. The plant's running costs are greatly reduced as a result of this.

The treatment of edible oil refinery wastewater has proven difficult over the years, due to the chemical and physical features of the influent and strict discharge regulations. The type of oil being refined and the refining process used, both have a significant impact on the effluent properties. As an internal pretreatment procedure, wastewater from edible oil refineries can be successfully treated utilizing biological techniques.

Conclusion

For efficient organic matter and nutrient removal from edible oil refinery wastewater, ASP and SBR are well suited. To avoid shocking the receiving wastewater treatment plants, additional phosphate removal may be needed via chemical addition.

All these factors are encouraging edible oil refineries to convert from traditional water treatment to mixed and advanced systems, along with corporate responsibility initiatives to reduce water usage.

Effluent treatment plant manufacturer for edible oil refineries

Netsol Water offer a wide range of specialized services, including design, installation, and commissioning, for the effluent treatment plants. In order to assist you satisfy quality standards in crucial refinery processes, and deliver the greatest output, our engineering team collaborates with your team. We offer practical solutions at very affordable prices, whether cooling tower water treatment, boiler water treatment, zero discharge, or other types of filtrations.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.