What is the Applications and use of Rim Flow Suction Clarifiers?

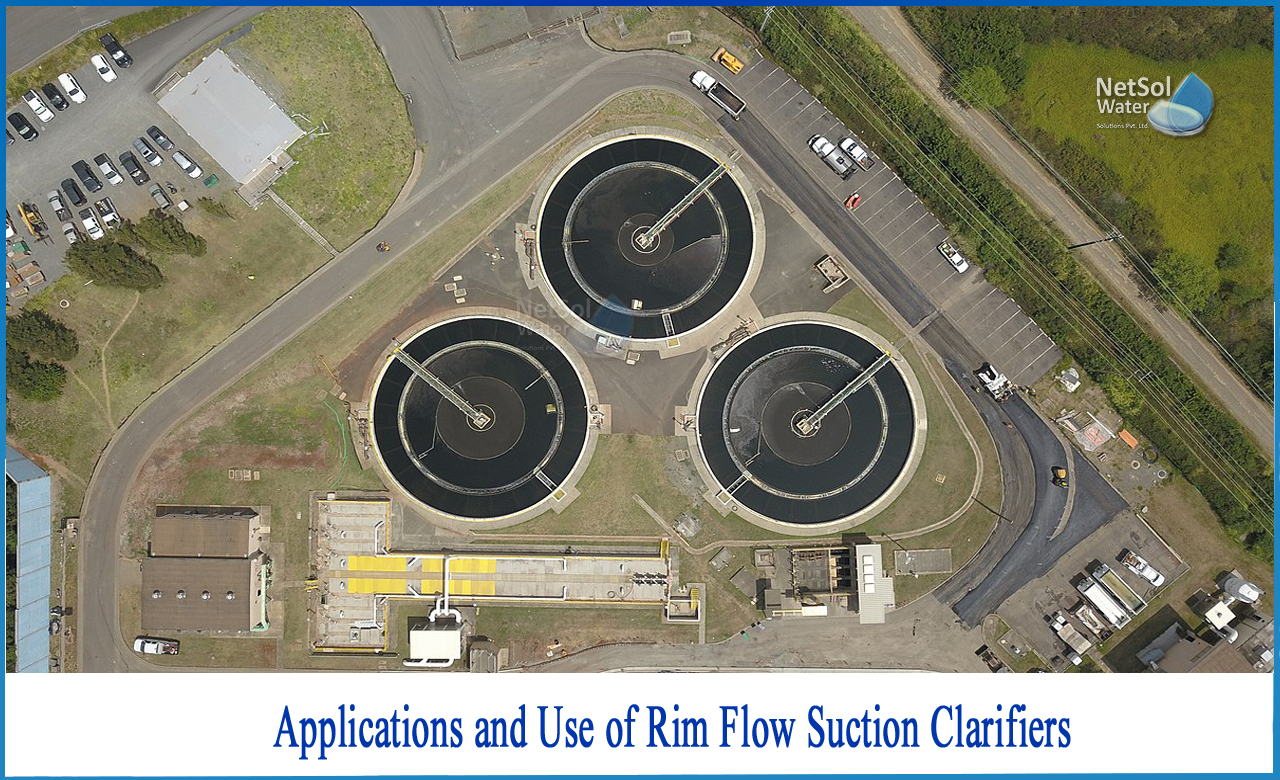

Rim flow suction clarifiers are clarifiers with an input along the rim and sludge sucked out at the floor using suction boxed arms instead of scrappers, which are said to reduce space and result in denser sludge’s, as well as a faster return to the aeration tank without the need for live sludge analysis.

Rim-Flow (influent/effluent) system encourages mixed liquor flow "away" from the effluent take-off. A big input area and modest entrance velocities help sludge flocculate well. It is possible to achieve a SOR (Surface Overflow Rate) of 800 to 1000 gal/day/ft2.

What happens in these clarifiers?

The microorganisms are separated using a secondary clarifier, leaving just clean water. The surplus (waste activated sludge) is sent to another site in the plant for further treatment, while some of the particles recovered in the secondary clarifier (return activated sludge) are delivered back to the aeration tank to treat more wastewater. The disinfection process begins with the clean water that runs from the top of the clarifier.

The channel's varying cross section aids in maintaining a consistent velocity in the channel, preventing sediments from settling out. A positive uniform distribution across the perimeter is provided by the limited influent.

Use of Rim-Flow Suction Clarifiers

1: With both the influent and effluent channels on the tank perimeter, the Rim-Flow Clarifier allows for excellent skimming of the whole tank surface as well as the influent raceway.

2: A scum barrier added to the effluent launder prevents accumulated surface scum from entering the effluent channel in the Rim-Flow Clarifier. A hinged wiper component ensures continual contact with the blade, scum baffle, and beach as it goes up the beach.

3: A blade installed on an extension of the skimmer arm provides influence channel skimming, which guides scum in the channel to a weir gate for disposal. The design of this skimmer prevents scum from spanning the channel.

Because hydraulic loadings vary so much, it's critical to know the exact link between channel profile, orifice size and placement, tank size, and overflow rates. All of these calculations are made using a computer model that has been proven by years of successful field experience with the Rim-Flow Clarifier.

Applications of Rim-Flow Clarifiers

Skimming on the Surface and in the Channel is one of the proven applications of rim flow suction clarifier. With both influent and effluent channels on the tank edge, the Rim-Flow system allows for excellent skimming of the whole tank surface as well as the influent raceway. Scum and grease particles are discharged during the aeration process and end up in final clarifiers, therefore this is a must in final clarifier design.

It also finds its application for diffusion that is complete and rapid.A baffle on the underside of the feed channel deflects the regulated flow as it enters the tank through the orifices. This barrier, together with the orifice length (which should never exceed the channel floor thickness), prevents "jetting" into the basin.

Why should you chose us for water and wastewater Treatment?

Netsol Water, based in Greater Noida, India, is a well-known industrial and commercial water and wastewater treatment plant manufacturer. We provide experienced treatment solutions for all of your needs. In accordance with industry standards, our treatment plants employ top quality raw materials and the most up-to-date equipment’s.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.